In the ever-evolving landscape of printing technology, UV DTF printing has quickly taken center stage as a transformative force. This innovative method, which stands for Ultraviolet Direct to Film printing, provides businesses with a powerful alternative to traditional printing methods. By utilizing UV light to cure ink during the transfer process, UV DTF printing produces stunningly vibrant colors and intricate designs on a variety of substrates, from plastic and metal to wood. As we dive into a detailed comparison of printing methods, we will explore the benefits and limitations of UV DTF printing versus older techniques such as screen printing. With a keen focus on durability and versatility, this examination aims to inform businesses seeking to enhance their production capabilities with the latest advancements in printing technology.

When referring to UV DTF printing, one can also consider this printing technique as Ultra-Violet Direct to Film printing, emphasizing its reliance on UV light for the curing process. This modern approach serves as a cutting-edge replacement for conventional styles of printing, such as screen and offset methods. The conversation around printing technologies is shifting, highlighting advancements that enable superior quality and efficiency in print production. As we evaluate these emerging techniques, we will discuss how the durability and vividness of prints differ dramatically from traditional methodologies, particularly in the context of applications where material variety and intricate detail are paramount. Engaging with this topic allows us to better understand the dynamic nature of the printing industry and its continuous push towards innovation.

Understanding UV DTF Printing Technology

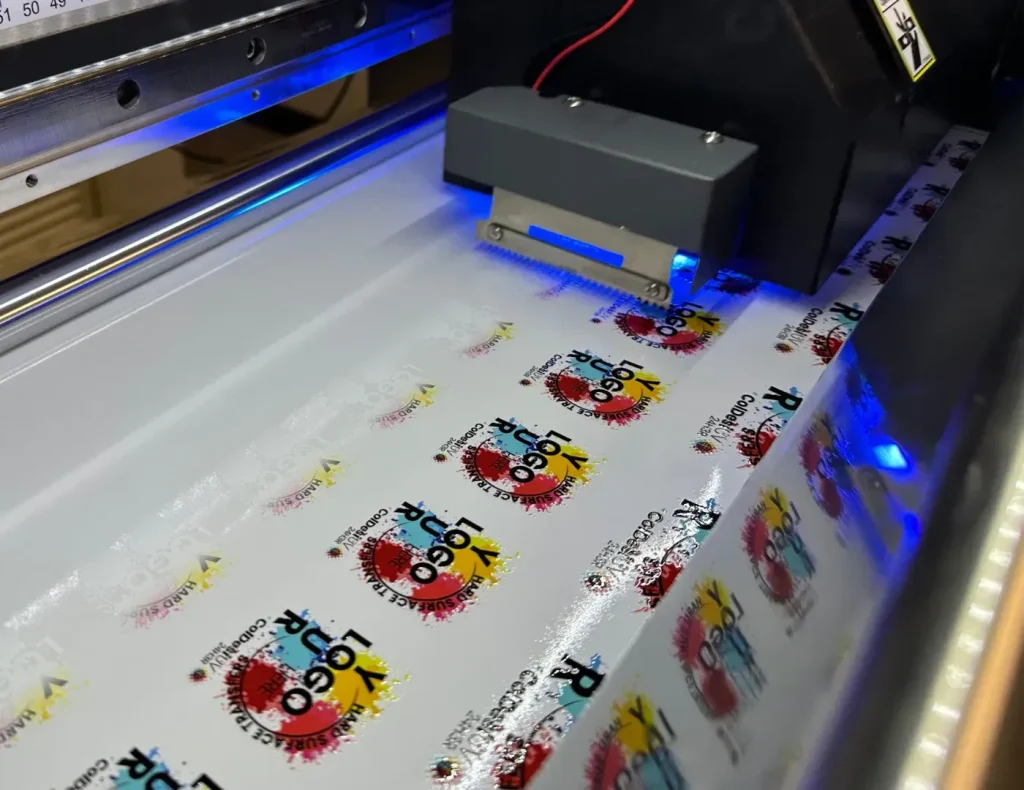

UV DTF printing, short for UV Direct to Film printing, is a cutting-edge technology that uses ultraviolet light to cure inks directly onto a substrate. This process allows for vibrant and detailed prints that can be achieved on a multitude of surfaces, including textiles, metals, and wood. Unlike traditional printing methods that may require a lengthy curing process, UV DTF printing delivers immediate results through its instant curing capabilities. Businesses can leverage this technology to produce high-quality images that are not only captivating but also boast durability under various conditions.

The versatility of UV DTF printing makes it a preferred choice among manufacturers looking to expand their printing capabilities. Unlike traditional methods like screen printing, which are often limited to specific materials and designs, UV DTF can handle intricate graphics and multiple substrates. Consequently, it opens up new avenues for customization and personalization in product offerings, which are increasingly demanded by consumers.

Comparison of UV DTF Printing and Traditional Methods

When comparing UV DTF printing to traditional methods such as screen printing and offset printing, several key differences emerge. Traditional methods often struggle with issues like color vibrancy and detail retention, especially on challenging materials. Screen printing, for instance, is effective for bulk orders but can fall short on intricate designs and varied substrates. Offset printing, while producing high-quality images, tends to be more costly and time-consuming for smaller production runs.

In contrast, UV DTF printing holds a distinct advantage due to its ability to deliver high-quality prints quickly and across a wide range of materials. The advanced technology facilitates detailed graphics and bright colors that resist fading, making it ideal for both indoor and outdoor applications. This in-depth comparison highlights UV DTF’s strengths in flexibility, speed, and quality, providing a compelling argument for businesses contemplating a transition from traditional methods.

The Durability of UV DTF Printing Compared to Traditional Techniques

Durability is a critical factor when selecting a printing method, especially for products that will be exposed to the elements. UV DTF printing excels in this area, offering prints that are resistant to scratching, fading, and environmental wear and tear. Traditional printing methods, such as digital and screen printing, often do not match this level of durability, particularly under harsh conditions. The resilience of UV DTF printed products makes them an excellent choice for signage, outdoor merchandise, and other applications requiring lasting visuals.

This durability is achieved through the unique curing process of UV inks, which solidifies the ink upon exposure to UV light. This makes it particularly advantageous for businesses aiming to produce long-lasting products without sacrificing quality or color integrity. The superior performance of UV DTF printing in durability is a significant consideration for any organization looking to ensure customer satisfaction and reduce the risk of reprinting.

Environmental Impact of UV DTF Printing

In today’s environmentally conscious market, the environmental impact of printing methods cannot be overlooked. UV DTF printing offers several eco-friendly advantages when compared to traditional printing techniques. Unlike screen printing, which may require large volumes of water and generate considerable waste, UV DTF printing consumes minimal resources and emits fewer volatile organic compounds (VOCs), making it a more sustainable option for businesses.

Using UV inks allows for less chemical waste and overall resource consumption, aligning with the goals of businesses aiming for sustainable practices. As consumers increasingly demand environmentally friendly products, adopting UV DTF printing can enhance a company’s reputation while fulfilling corporate social responsibilities associated with eco-friendliness in production.

Market Trends in Printing Technology

The printing industry is witnessing significant shifts due to technological advancements, notably the rise of UV DTF printing. As companies seek customization and shorter production runs, UV DTF offers the necessary efficiency to meet evolving market demands. This trend reflects a broader movement towards on-demand printing, which allows businesses to maximize their offerings while minimizing waste.

Incorporating UV DTF technology is not merely about enhancing production capabilities; it also positions companies strategically within the competitive landscape. As more businesses transition to this modern printing technology, it sets a new standard for quality and service in the industry, ensuring that businesses remain relevant and capable of meeting customer expectations.

Evaluating Costs: UV DTF vs Traditional Printing

While UV DTF printing presents a host of advantages, the initial cost can be a point of contention for smaller businesses. The expense associated with purchasing a UV printer and the higher cost of inks compared to traditional methods can make it challenging for organizations with limited budgets. However, it is crucial to evaluate these costs in the context of the long-term benefits that UV DTF offers, such as speed, quality, and durability.

In essence, while traditional printing methods may present lower upfront costs, the longevity and reduced need for reprints associated with UV DTF technology can lead to cost savings over time. Businesses must weigh these factors carefully, considering their production needs and projected demand in order to determine the most financially viable printing method.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional printing methods?

UV DTF printing stands for Ultraviolet Direct to Film printing, a modern technique that utilizes UV light to cure ink instantly onto various substrates. Unlike traditional printing methods such as screen printing and offset printing, which often require longer drying times and have limitations in color vibrancy and material compatibility, UV DTF printing offers faster production speeds, vibrant colors, and the ability to print on a diverse range of materials like metal, wood, and plastic.

How does the durability of UV DTF printing compare to traditional printing methods?

The durability of UV DTF printing is significantly higher than that of many traditional printing methods. UV DTF prints are resistant to scratching, fading, and harsh environmental conditions, making them ideal for outdoor and high-use applications. In contrast, traditional printing methods may struggle with longevity, especially when faced with exposure to the elements or everyday wear and tear.

What are the cost implications of adopting UV DTF printing versus traditional printing methods?

While UV DTF printing can offer high-quality results and efficiency, the initial investment in UV printing technology is generally higher than traditional printing setups. The costs of UV inks and film materials can also be more substantial. However, businesses may find that the long-term benefits, such as improved print quality and durability, justify the initial costs compared to traditional methods.

What advantages does UV DTF printing have over screen printing?

One of the key advantages of UV DTF printing compared to screen printing is its versatility and ability to achieve intricate designs with vibrant colors. While screen printing is cost-effective for large volumes, it often has limitations in terms of detail and material compatibility. UV DTF’s instant curing process allows for precise and colorful outputs that stand out more than traditional screen-printed designs.

In what ways is UV DTF printing considered more environmentally friendly than traditional printing methods?

UV DTF printing is often regarded as more environmentally friendly because it typically requires less water, generates less waste, and uses UV inks that emit minimal volatile organic compounds (VOCs). In contrast, many traditional printing methods consume more resources and may have a higher environmental impact due to chemical runoff and ink waste.

What market trends are influencing the adoption of UV DTF printing technology?

Market trends such as the increasing demand for custom products and short-run production capabilities are driving the adoption of UV DTF printing technology. As businesses look for faster turnaround times and high-quality prints that meet consumer expectations, UV DTF printing is gaining popularity across various industries, showcasing its ability to provide detailed and vibrant results efficiently.

| Aspect | UV DTF Printing | Traditional Printing Methods |

|---|---|---|

| Definition | Modern technique using UV light to cure ink on various surfaces | Includes techniques like screen, offset, and digital printing |

| Advantages | 1. Versatility across multiple substrates 2. Vibrant colors and intricate details 3. Fast production with instant curing |

1. Cost-effective for large volumes 2. High-quality outcomes (especially in offset printing) 3. Suitable for bulk runs and simple designs |

| Disadvantages | 1. Higher initial costs 2. May require additional post-processing |

1. Limited vibrancy and material compatibility 2. Time-consuming for smaller batches |

| Durability | Highly durable, resistant to scratches and fading | Generally less durable compared to UV DTF |

| Environmental Impact | More eco-friendly, using less water and reducing VOC emissions | Typically more wasteful and higher VOC emissions |

| Market Trends | Growing popularity due to demand for customization and speed | Established but challenged by the shift towards modern techniques |

Summary

UV DTF printing has become a revolutionary force in the printing industry, standing out due to its unmatched versatility and vibrant output. This modern method allows for the application of high-quality prints on a diverse range of materials, satisfying the rising consumer demand for customization and quick turnaround times. Despite the higher initial costs associated with UV DTF printing, its advantages including enhanced durability and environmental benefits make it a compelling choice for businesses aiming for excellence. As the printing landscape continues to evolve, embracing UV DTF technology may be the key to staying competitive in a fast-paced market.