DTF transfers, or Direct to Film transfers, have revolutionized the way designers create custom apparel in the textile printing sector. This groundbreaking technique merges the efficiency of Direct to Garment (DTG) printing with the reliability of traditional heat transfer methods, providing an exceptional solution for vibrant, high-quality prints. As we delve deeper into the world of DTF printing, we’ll uncover its myriad advantages, including versatility across various fabrics and ease of use for both novices and professionals. What sets DTF transfers apart is not just their visual appeal; they also cater to the growing demand for sustainable printing practices, making them an eco-friendly alternative in an industry striving for greener solutions. Join us as we unlock the power of DTF transfers and explore how this technology is reshaping custom apparel production.

Direct to Film printing, often referred to as DTF transfers, is a modern and innovative approach to textile printing that has gained significant traction. This technique is paving the way for unique designs on various materials, allowing businesses and individuals alike to create personalized clothing with ease. By utilizing advanced printing technologies, this method provides remarkable detail and vibrant colors, setting a new standard in the custom apparel market. With an eye towards sustainability, DTF printing employs environmentally friendly practices, aligning with contemporary consumer preferences. Discovering the ins and outs of this method will equip you with the knowledge to harness its potential for your own textile projects.

Understanding DTF Transfers and Their Impact on Textile Printing

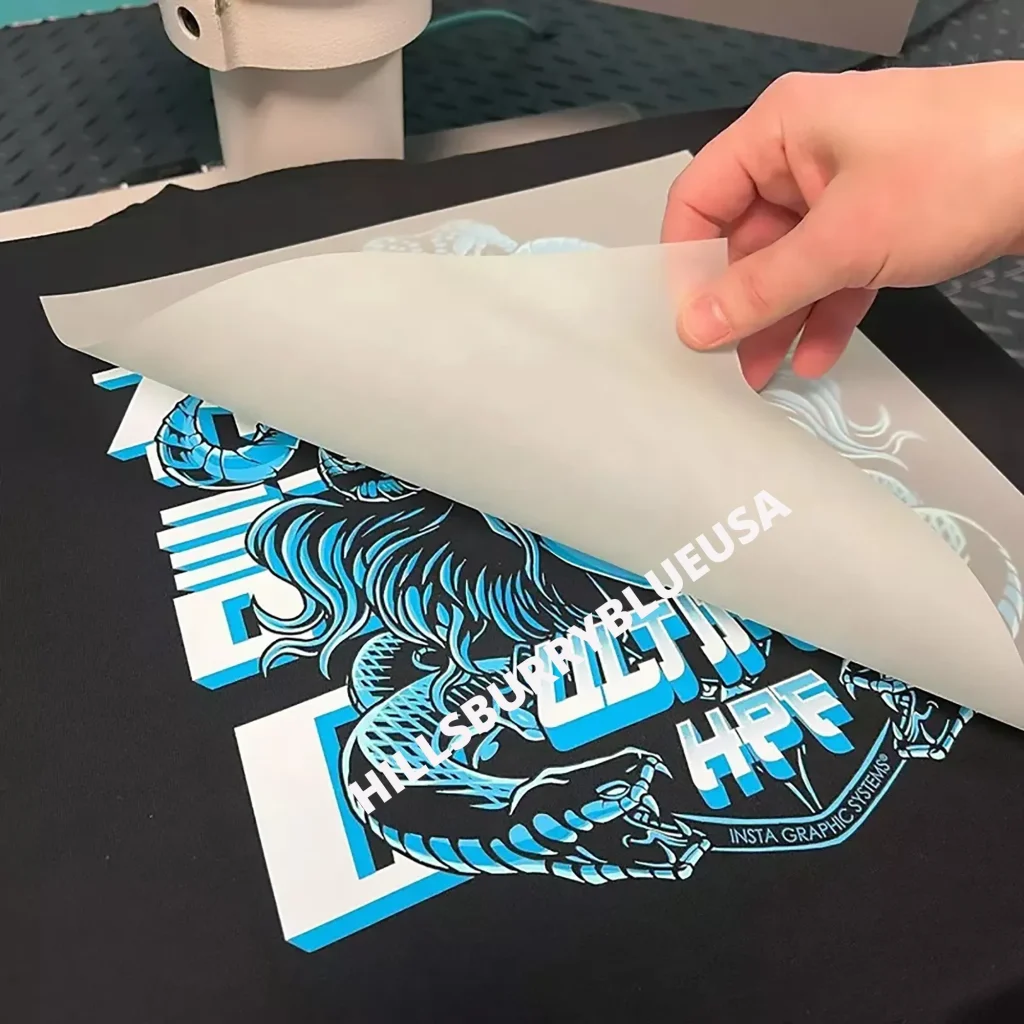

DTF transfers represent a significant advancement in textile printing technology. They allow for vibrant and intricate designs to be duplicated onto a wide variety of fabrics, making them an ideal choice for custom apparel production. This flexibility is particularly appealing to designers who seek to deliver unique and personalized clothing items that cater to modern consumer preferences. The DTF printing process is straightforward: designs are printed on a special film that is then heat-pressed onto the fabric, creating a beautiful and lasting imprint. As such, DTF has become a preferred method for those looking to combine quality with efficiency.

The impact of DTF transfers on the textile industry cannot be overstated. Not only do they simplify the printing process, but they also reduce the need for extensive setups typical of traditional methods such as screen printing. This innovation caters to both small businesses looking to minimize startup costs and larger enterprises aiming for quick turnaround times without sacrificing print quality. Moreover, DTF’s ease of use and adaptability to different fabric types has encouraged a broader range of applications, from fashion to promotional items, further transforming the landscape of textile printing.

The Benefits of DTF Transfers for Custom Apparel

One primary advantage of DTF transfers is their ability to produce high-quality prints with exceptional detail and vibrancy. The process is capable of reproducing complex graphics that are often challenging with traditional printing techniques. This capability is essential for garment personalization, allowing businesses to cater to niche markets that demand standout designs. Custom apparel created with DTF printing not only satisfies aesthetic appeals but also ensures that the finished products boast durability and resilience against wear and tear.

In the realm of custom apparel, DTF transfers offer unmatched versatility, enabling the printing of designs on various fabric types, including cotton, polyester, and blends. This characteristic is particularly advantageous for brands that want to diversify their product offerings without investing in multiple printing techniques. The compatibility with various textiles expands the creative possibilities for designers while also meeting the practical needs of consumers. Consequently, businesses can maintain a competitive edge by producing a wide range of high-quality, customized clothing.

Sustainability Considerations in DTF Printing

With growing global concerns about environmental sustainability, DTF printing presents an eco-friendly alternative to traditional textile printing methods. Many manufacturers are adopting sustainable practices within their DTF processes, using inks that are free from harmful chemicals and utilizing recyclable films. This shift aligns with the increasing consumer demand for green products and helps brands attract environmentally conscious buyers. By choosing DTF printing, companies not only reduce their carbon footprint but also position themselves as leaders in sustainable fashion.

Moreover, the sustainability aspect of DTF transfers extends beyond materials and inks. The ability to produce high-quality prints with minimal waste is another benefit that aligns with sustainable printing practices. DTF printing leads to fewer off-cuts and excess products, resulting in less waste during production. As the fashion industry continues to grapple with its impact on the environment, adopting approaches like DTF that prioritize sustainability will be critical for long-term viability.

Cost Efficiency of DTF Transfers in Textile Production

Cost efficiency is a deciding factor for many startups and small businesses entering the custom apparel market. DTF transfers stand out as a budget-friendly solution as the initial investment in required equipment is relatively low compared to other printing methods such as screen printing. This affordability allows budding entrepreneurs to experiment with various designs and production processes without the financial burden that higher costs typically impose. DTF provides an accessible entry point, enabling more players to partake in the competitive world of customized fashion.

Furthermore, DTF transfers offer substantial savings in material usage and energy consumption. The quick setup time and reduced need for screens help businesses maximize profitability by decreasing production delays. Since the DTF process is streamlined, brands can take on more orders and fulfill customer demands efficiently. Overall, the economic benefits associated with DTF printing empower businesses to scale their operations while delivering quality products at competitive prices.

Technological Innovations Shaping DTF Transfers

The DTF printing landscape is continuously evolving, thanks to technological innovations that enhance speed, print quality, and user-friendliness. Advances in printing technology have led to specialized DTF printers being introduced to the market, designed to optimize the DTF process while producing consistent high-quality outputs. Brands like Epson are at the forefront of this transformation, providing improved ink systems that increase the vibrancy and adhesion of prints on textiles.

In addition to printer advancements, software technologies have also improved design creation and file management for DTF printing. Users now have access to powerful design tools that facilitate intricate graphics creation, making it easier to take concepts from imagination to reality. These technological innovations not only bolster the capabilities of DTF transfers but also redefine industry standards for quality and creativity in textile printing.

Future Trends of DTF Transfers in the Apparel Industry

As the textile printing industry evolves, so too does the role of DTF transfers in shaping future trends. One of the most significant movements is the increasing focus on customization, with consumers seeking more personalized and unique products. DTF printing’s capabilities allow brands to respond quickly to this trend, offering custom designs in small to medium batch sizes without compromising on quality. This agility positions DTF as a crucial player in the growing demand for individualized merchandise.

Additionally, the rise of e-commerce and online marketplaces has accelerated the need for flexible printing methods like DTF. As online shopping continues to dominate, businesses must adapt to provide rapid product offerings and tailored options for their customers. With its efficient production process and high-quality output, DTF transfers will undoubtedly play a pivotal role in meeting these market demands, paving the way for the future of custom apparel and textile printing.

Frequently Asked Questions

What are DTF transfers in textile printing?

DTF transfers, or Direct to Film transfers, are a cutting-edge printing technique that involves printing designs onto a specialized film, which is then heat-pressed onto fabrics. This method allows for vibrant, high-quality prints that are durable and suitable for various custom apparel applications.

How do DTF transfers compare to other printing methods?

DTF printing stands out for its ability to produce detailed and colorful designs with less complexity than traditional methods like screen printing. Unlike Direct to Garment (DTG) printing, DTF transfers can be used on a wider range of fabrics, making them a versatile choice for custom apparel.

What are the benefits of using DTF transfers for custom apparel?

The benefits of DTF transfers include vibrant color reproduction, high detail retention, and adaptability across different fabric types. Additionally, DTF transfers are user-friendly, making them accessible for both small businesses and large printing operations, while also being cost-effective.

Are DTF transfers a sustainable printing option?

Yes, DTF printing can be considered a sustainable printing option as it often utilizes eco-friendly inks and films. This aligns with the growing consumer demand for environmentally conscious products, helping companies reduce their ecological footprint while still producing vibrant custom apparel.

What equipment is needed for DTF printing?

To start DTF printing, you’ll need a DTF printer, specialized transfer film, adhesive powder, and a heat press. These essential components allow you to create high-quality prints that can be applied to various textiles, making DTF a versatile and efficient option in the textile printing industry.

How durable are prints made with DTF transfers?

DTF transfers are known for their durability, standing up well against fading and cracking over time. This resilience makes them an excellent choice for custom apparel, as they help maintain a brand’s quality and appeal in the competitive clothing market.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers print designs onto a special film to transfer direct to fabrics using heat. |

| Market Demand | The demand for customized apparel is driving DTF market growth as consumers seek personalized clothing. |

| Technological Advances | Innovations have made DTF systems more efficient with specialized printers and better ink formulations. |

| Sustainability Efforts | DTF incorporates eco-friendly inks and materials, appealing to environmentally conscious buyers. |

| Cost Efficiency | Declining equipment costs make DTF more accessible for small businesses. |

| Advantages of DTF Transfers | Vibrant prints, versatility on various fabrics, ease of use, and durability are key benefits. |

| The Process of DTF Transfers | The DTF process includes design creation, film printing, powder application, and fabric transfer. |

Summary

DTF transfers represent a transformative breakthrough in the textile printing industry. By utilizing this innovative approach, businesses can achieve high-quality, vibrant designs with remarkable durability on a variety of fabrics. This growing method not only meets the increasing consumer demand for customized apparel but also prioritizes sustainability and cost efficiency, making it an attractive option for both small-startups and large enterprises. As this printing technique continues to evolve, DTF transfers are set to redefine the future of garment printing.