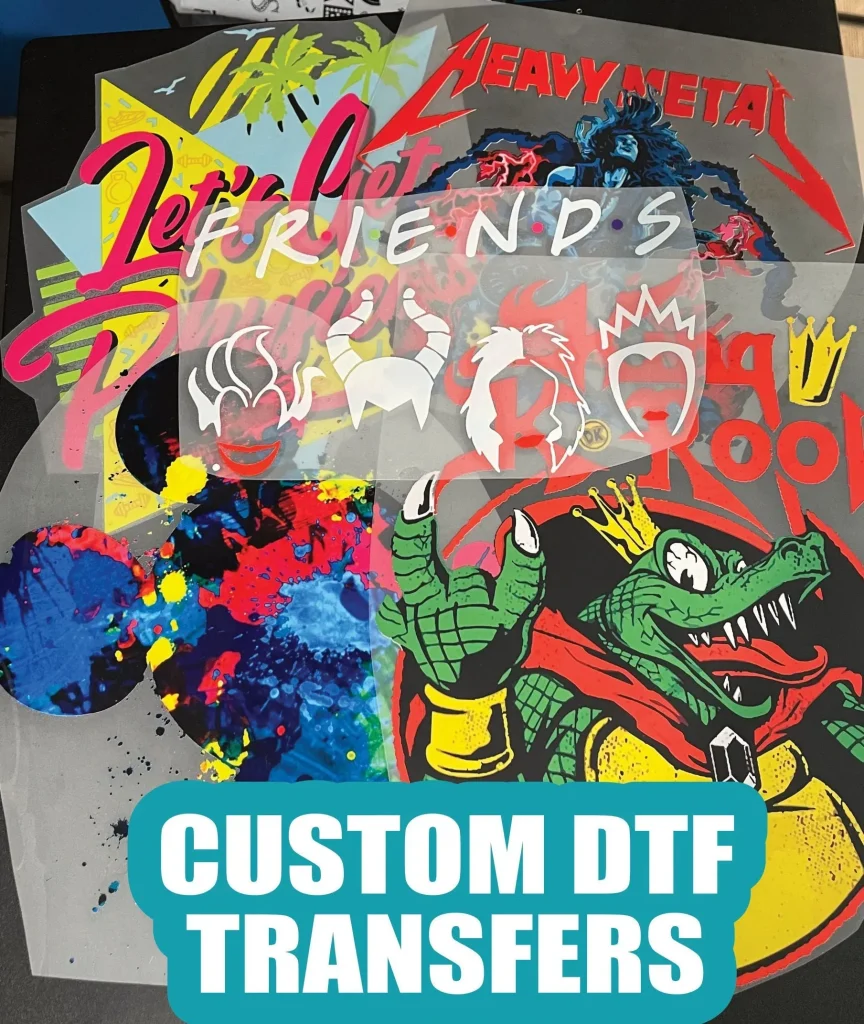

DTF transfers, or Direct to Film transfers, represent a groundbreaking leap in the world of custom apparel. This innovative printing technique allows creators to transfer stunning designs onto various fabrics with impressive ease and precision. For beginners venturing into the realm of heat transfer printing, understanding the DTF printing process is paramount for delivering high-quality results. Whether you’re seeking a unique way to express your creativity or considering a business opportunity in custom apparel, DTF transfers can elevate your crafting journey. Join us as we delve deeper into the fundamentals of this exciting method, providing you with a comprehensive beginner DTF guide to unlock your potential!

Direct to Film printing employs advanced technology to achieve remarkable results in the customization of fabrics. This technique is becoming increasingly popular among DIY enthusiasts and professional printers alike, as it provides a user-friendly approach to heat transfer applications. With its ability to produce vibrant, durable prints, it holds significant advantages for those looking to create personalized clothing or other textile products. Understanding this innovative printing method is essential for anyone interested in enhancing their skills in apparel customization. In this exploration of DTF transfers, we’ll uncover the steps, tools, and tips necessary to successfully implement this process.

Understanding DTF Transfers: The Basics

DTF transfers, or Direct to Film printing, represent an innovative approach to fabric customization that combines high-quality image reproduction with user-friendly techniques. Understanding the basics of DTF printing is crucial for anyone interested in venturing into custom apparel or garment decoration. This technique employs a unique printer that applies pigment inks directly onto a specially coated film that serves as the medium for your design. After being printed, a hot melt adhesive powder is applied, which helps bond the image to the fabric during heat transfer.

The appeal of DTF transfers lies in their ability to create detailed and vibrant designs that are durable and long-lasting. Unlike traditional printing methods, DTF allows for the printing of intricate designs with multiple colors, making it an ideal choice for custom apparel projects. As a beginner, becoming familiar with the DTF process not only enhances your skills but also equips you with the knowledge needed for various fabric types, as DTF works effectively on cotton, polyester, and blends alike.

The DTF Printing Process Explained

To truly master DTF transfers, understanding the detailed steps in the DTF printing process is essential. It begins with the creation of your design, which can be done using graphic software like Adobe Illustrator. Once the design has been finalized, it is printed onto DTF film using a specialized DTF printer. The next critical step involves applying the adhesive powder onto the wet printed design, where it is then cured under heat to bond properly with the ink.

After curing, the final phase consists of using a heat press to transfer the printed design onto your fabric. This combination of heat and pressure activates the adhesive properties and ensures a solid bond. Knowledge of this process helps beginners troubleshoot common issues such as adhesive application and heat settings, which can significantly impact the final output of their custom apparel.

The Key Benefits of DTF Transfers

DTF transfers come with a plethora of advantages that make them a preferred choice for many designers and small businesses looking to create custom apparel. The versatility of DTF printing is one of its standout features; it can be used on a wide range of fabrics, from t-shirts to bags, allowing for limitless creativity in product offerings. This flexibility opens up new markets for your designs, moving beyond just clothing to various promotional items.

Another remarkable benefit of DTF transfers is the color vibrancy achieved through this process. The pigments used in DTF ink are often brighter and more resilient, maintaining their brilliance even after numerous washes. For businesses that emphasize quality and customer satisfaction, this durability ensures that products remain appealing and professional long after they’ve been produced.

Essential Equipment for DTF Printing

Starting your DTF printing journey requires specific equipment to ensure high-quality outputs. A specialized DTF printer is essential, as it must be capable of printing with pigment inks that adhere appropriately to the transfer film. Brands like Epson and Brother are known for their reliable printers suited for this niche. Alongside a printer, investing in a good heat press machine is vital; this tool is necessary for achieving the correct temperature and pressure needed to transfer your designs effectively.

Additionally, you will need hot melt adhesive powder, which is a key component in the DTF process. This adhesive acts as the binding agent between the ink and fabric, making it an important supplier item for any user. Understanding which brands to trust for these components can streamline the setup process and significantly improve your quality of work.

Getting Started with DTF Transfers: Tips for Beginners

For those new to DTF transfers, starting out may seem daunting. However, by following a few straightforward steps, you can ease into the process. Initially, take the time to learn about your equipment and conduct a few test runs on various fabrics to get accustomed to how the DTF printing process works. Experimenting with different fabrics will help you refine your pressure and temperature settings, which are crucial for achieving optimal results.

Joining online communities and forums dedicated to DTF printing is another excellent strategy for beginners. Engaging with experienced users can provide valuable insights into troubleshooting common problems and learning from others’ successes. As you navigate your journey in DTF printing, remember that practice and patience are key, allowing you to grow and improve your custom apparel designs.

Exploring Market Trends in DTF Printing

The landscape of DTF printing is evolving rapidly, and it’s essential to stay updated with current market trends. The demand for DTF transfers has surged as businesses recognize the need for quick turnaround times and the ability to create personalized designs on demand. As a beginner in the custom apparel space, leveraging this trend can help propel your business forward, catering to niche markets that prioritize unique and vibrant designs.

Moreover, the shift toward eco-friendly options within the DTF printing industry is noteworthy. As sustainability becomes a priority, manufacturers are increasingly developing eco-friendly inks and films. This transition offers a dual advantage: reducing environmental impact and appealing to a conscientious consumer base that values sustainable practices. Embracing these trends will not only enhance your brand image but can also help you attract a broader audience.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve printing high-quality designs onto a specially coated film, which is then adhered to fabrics using heat and pressure. The process includes creating a digital design, printing it on film with a DTF printer, applying adhesive powder, and finally transferring the design onto the fabric with a heat press.

What equipment do I need for the DTF printing process?

To begin with DTF transfers, you will need a specialized DTF printer compatible with pigment inks, a heat press machine to transfer the design onto fabric, and hot melt adhesive powder that bonds the prints to the fabric during the heat transfer process.

Is DTF printing suitable for custom apparel production?

Yes, DTF printing is highly suitable for custom apparel as it offers versatility across various materials, including cotton, polyester, and blended fabrics. This makes it ideal for t-shirts, hoodies, bags, and other clothing items, allowing for vibrant and durable designs.

What advantages do DTF transfers offer for beginners in printing?

DTF transfers are beginner-friendly due to their straightforward process and reduced setup time compared to traditional methods like screen printing. They also allow for cost-effective smaller batch production, making them ideal for newcomers looking to experiment with custom designs.

Can I produce eco-friendly custom apparel with DTF transfers?

Absolutely! Many manufacturers are now offering eco-friendly inks and films for DTF printing. This allows you to produce sustainable custom apparel while still benefiting from the vibrant output and versatility that DTF transfers provide.

Where can I find resources to learn more about the DTF printing process?

There are various resources available for learning about DTF printing, including YouTube tutorials, online courses on platforms like Udemy, and community forums on sites like Reddit. These resources can help you gain insights and improve your skills in DTF transfers.

| Feature | Details |

|---|---|

| What Are DTF Transfers? | A printing technique where high-quality images are printed onto a film for transfer to fabric. |

| Process Overview | 1. Design creation 2. Printing on film 3. Adhesive application 4. Heat transfer |

| Advantages | Versatile for various materials, vibrant colors, easy to use, and cost-effective for small batches. |

| Required Equipment | Specialized DTF printer, heat press machine, adhesive powder. |

| Market Trends | Growing popularity; increasing availability of eco-friendly options. |

| Tips for Beginners | Invest time in learning, conduct test runs, join online communities. |

Summary

DTF Transfers are revolutionizing the custom printing industry, providing an efficient, vibrant, and user-friendly method for creating personalized apparel. This innovative process not only caters to a variety of fabric types but also allows users to achieve professional-quality designs with minimal startup costs. As the popularity of DTF printing continues to rise, it opens up numerous opportunities for both hobbyists and entrepreneurs, making it an essential topic for anyone looking to dive into the world of custom apparel. Embracing DTF Transfers today means unlocking a future of endless creative potential.