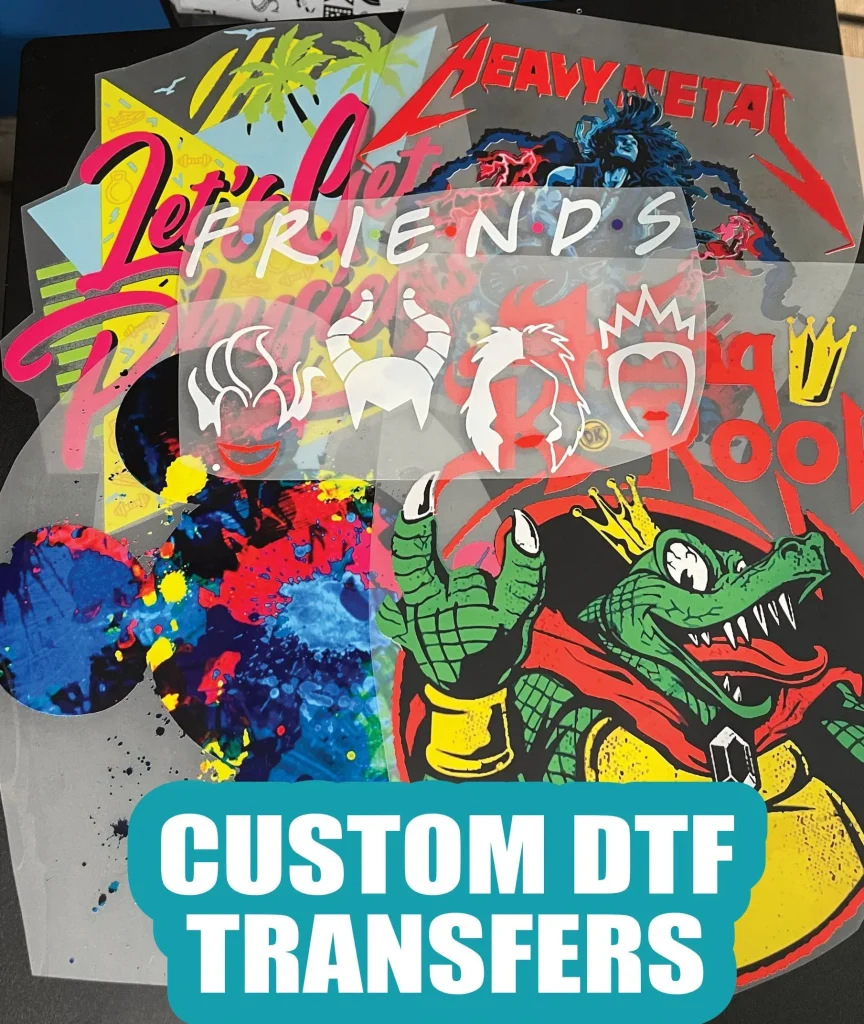

DTF transfers, or Direct to Film transfers, are revolutionizing the world of custom printing by offering vibrant and complex designs that can be easily applied to various fabrics. This innovative printing technique has gained widespread popularity among artists, designers, and small business owners seeking to elevate their products. By leveraging DTF printing techniques, you can achieve high-quality images that are not only visually striking but also durable and long-lasting. In this guide, we will share essential DTF transfer tips to help you maximize your designs and craft standout apparel. Whether you’re a seasoned professional or just starting, understanding how to use DTF transfers will open up exciting possibilities for your creative endeavors.

Exploring the realm of Direct to Film printing opens doors to diverse techniques that enhance fabric decoration. Known for its ability to produce intricate designs with stunning detail, DTF printing stands apart from traditional methods like screen printing and vinyl cutting. As we delve into the best practices for DTF, we will cover everything from essential tools to the critical aspects of application that can make or break your projects. This comprehensive insight into DTF transfer methods will equip you with the knowledge to experiment and create dynamic prints that truly engage your audience. Join us as we uncover the impact of effective DTF techniques on your artistic journey.

Understanding the Fundamentals of DTF Transfers

DTF (Direct to Film) transfers are a revolutionary method in the realm of fabric printing. By enabling intricate designs and vibrant colors, DTF transfers distinguish themselves from conventional printing methods such as screen printing or heat transfer vinyl. The technique involves printing a digital image onto a special film, which is then heat-pressed onto the desired fabric. This allows for clarity and detail in designs, even those with gradual color transitions or complex patterns, which are challenging to achieve with other techniques.

The fundamental process of DTF transfers begins with proper preparation, including selecting high-quality transfer films and inks suited for the fabric types. Understanding these materials is crucial, as the choice directly impacts how well the design adheres and withstands wear. With the right materials and techniques, DTF printing opens up a world of possibilities for artists and businesses alike, enabling them to create personalized, captivating designs that resonate with customers.

Essential Tools for Successful DTF Printing

Equipping yourself with the right tools is pivotal for maximizing the potential of DTF transfers. A reliable DTF printer is paramount since it needs to provide accurate color reproduction and maintain the necessary resolution for detailed designs. Additionally, investing in a high-quality heat press that can evenly distribute temperature and pressure will drastically improve the outcome, ensuring that your transfers adhere well and last longer.

Furthermore, selecting appropriate DTF transfer film is critical. The film should be stretchable and compatible with the types of designs you plan to create. Quality DTF inks are equally important as they affect the vividness and durability of the final transfers. By assembling the correct tools, you lay the foundation for achieving stunning results in your printing projects.

Lastly, having additional accessories like Teflon sheets can improve the transfer process by protecting both the film and fabric during heat application. Taking the time to prepare your toolkit can significantly affect not just the aesthetic quality of your prints but also their longevity and resilience.

Mastering Key Techniques for DTF Transfers

Understanding DTF transfer techniques is crucial in achieving high-quality prints. Factors such as temperature, pressure, and curing time play a significant role in determining the success of your prints. Optimal temperature settings usually fall between 320°F to 350°F, depending on the fabric and DTF film used. It’s essential to have a calibrated heat press to maintain these temperatures consistently.

In addition to temperature, even application of pressure is vital. Each fabric will respond differently, so adjusting the pressure settings on your heat press according to the specific material can lead to better adhesion and crisp finishes. On top of this, proper curing time is crucial; this will vary from 10 to 20 seconds based on the materials used. Mastering these elements will provide you with the knowledge needed to experiment confidently and achieve the results you desire.

Effective Design Creation Strategies

Creating compelling designs is an integral part of the DTF transfer process. Utilize high-resolution images to ensure that clarity is maintained once the design is printed onto the transfer film. Any blurring or pixelation in your original images will be magnified in the final print, so it is paramount to start with quality assets.

Another key factor in design creation is channeling creativity through effective layering and color separation. Whenever your designs consist of multiple colors or layers, making sure they are organized properly within your design software is critical. This manipulation directly affects the final appearance of the design post-transfer, leading to vivid yet clean results.

Best Practices for Applying DTF Transfers

Successful application of DTF transfers requires a few best practices to maximize the potential of your prints. For instance, using a Teflon sheet over your transfer during the heat press application can prevent scorching and uneven heat distribution, which can jeopardize the quality of the design. This additional layer of protection aids in maintaining a consistent temperature, ultimately improving transfer outcomes.

Furthermore, pre-pressing your garment can significantly enhance the effectiveness of your DTF transfer application. By prepping the fabric for a few seconds to eliminate moisture and wrinkles, you create a smooth surface that allows for better adhesion of the transfer. This not only offers a professional finish but also extends the longevity of the design on the fabric.

Calculating Costs for DTF Transfers in Business

For businesses looking to leverage DTF transfers, understanding the financial aspects is vital for profitability. Begin by carefully evaluating the costs associated with materials—this includes your DTF film, inks, and operational expenses for your heat press. Knowing these numbers allows for more accurate pricing of your finished goods.

Moreover, consider the ROI for acquiring DTF-specific equipment. Although there may be an initial investment, the potential for high-quality, customizable prints can significantly increase your revenue streams. By factoring in all expenses and designing a clear pricing model, you position yourself effectively within the market, ensuring sustainable growth.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs on a special transfer film that is then heat-pressed onto fabric. This method allows for vibrant, full-color prints, suitable for various types of materials.

What are some tips for achieving high-quality DTF transfers?

To ensure high-quality DTF transfers, control key factors such as temperature and pressure during the heat application. Experiment with settings between 320°F to 350°F, and ensure even pressure is applied. Additionally, use high-resolution images for designs and choose quality DTF inks for better durability.

How do I choose the right materials for DTF transfers?

When selecting materials for your DTF transfers, prioritize high-quality DTF film that is both stretchable and compatible with your design. Use DTF inks specifically designed for this printing method to achieve vibrant colors and enhance print longevity.

What are the best practices for applying DTF transfers?

Best practices for applying DTF transfers include pre-pressing the garment to eliminate moisture, using a Teflon sheet to protect the transfer during heat application, and adhering to the recommended curing times of 10 to 20 seconds for optimal results.

Can I use DTF transfers on different fabric types?

Yes, DTF transfers are versatile and can be used on various fabric types, including cotton, polyester, and blends. However, it’s essential to test your designs on scrap fabric first to determine the best settings and ensure a successful transfer.

What equipment do I need to start using DTF transfers?

To get started with DTF transfers, invest in a reliable DTF printer, a quality heat press, and high-quality DTF transfer films and inks. These tools are crucial for producing vibrant designs and ensuring successful transfers.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | Versatile printing method that uses heat to transfer designs from a film onto fabric, allowing for intricate designs. |

| Essential Tools for DTF Transfers | DTF Printer, Heat Press, DTF Transfer Film, DTF Inks |

| Tips for Stunning DTF Designs | Control temperature (320°F-350°F), pressure, and curing time; experiment with test prints; use high-resolution images; ensure proper color separation; and choose quality materials. |

| Best Practices for Application | Use a Teflon sheet to prevent scorching and pre-press garments to remove moisture and wrinkles. |

| Calculating Costs and Profit Margins | Calculate costs of materials and operational costs to set profitable pricing for products. |

Summary

DTF transfers are a remarkable way to elevate your design capabilities in the printing world. With the right equipment, techniques, and materials, you can achieve stunning outcomes that stand out. By mastering the key processes involved—such as controlling temperature, pressure, and choosing quality inks—you can create vibrant designs that last on various fabrics. The investment in high-quality tools and a willingness to experiment will lead to professional results that can benefit artists, designers, and businesses alike. DTF transfers not only expand your creative possibilities but also enable you to make a significant impact in the competitive market of custom apparel and textile design.