DTF Transfers, or Direct to Film transfers, are transforming the landscape of custom apparel by delivering vibrant, high-quality designs that resonate with consumers. In an era where personalization is key, this innovative print technology stands out as a versatile solution for garment decoration. Through DTF printing, businesses can produce intricate graphics on various fabric types, ensuring a match for every creative vision. This heat transfer printing method not only exceeds traditional printing possibilities but also offers durability that withstands the test of time. In this article, we’ll explore the myriad benefits of DTF transfers and why they may be the game-changing addition your apparel design needs.

In the realm of personalized clothing, Direct to Film printing represents a groundbreaking advancement that allows for impressive customization options. Often referred to as DTF technology, this innovative approach to textile decoration combines precision with creativity, enabling detailed and colorful designs that appeal to a broad market. By utilizing state-of-the-art heat transfer techniques, this method elevates the quality of custom apparel, making it suitable for various fabrics. As we delve deeper into this revolutionary print method, we’ll uncover how its unique attributes can elevate your apparel design strategies while meeting modern consumer demands.

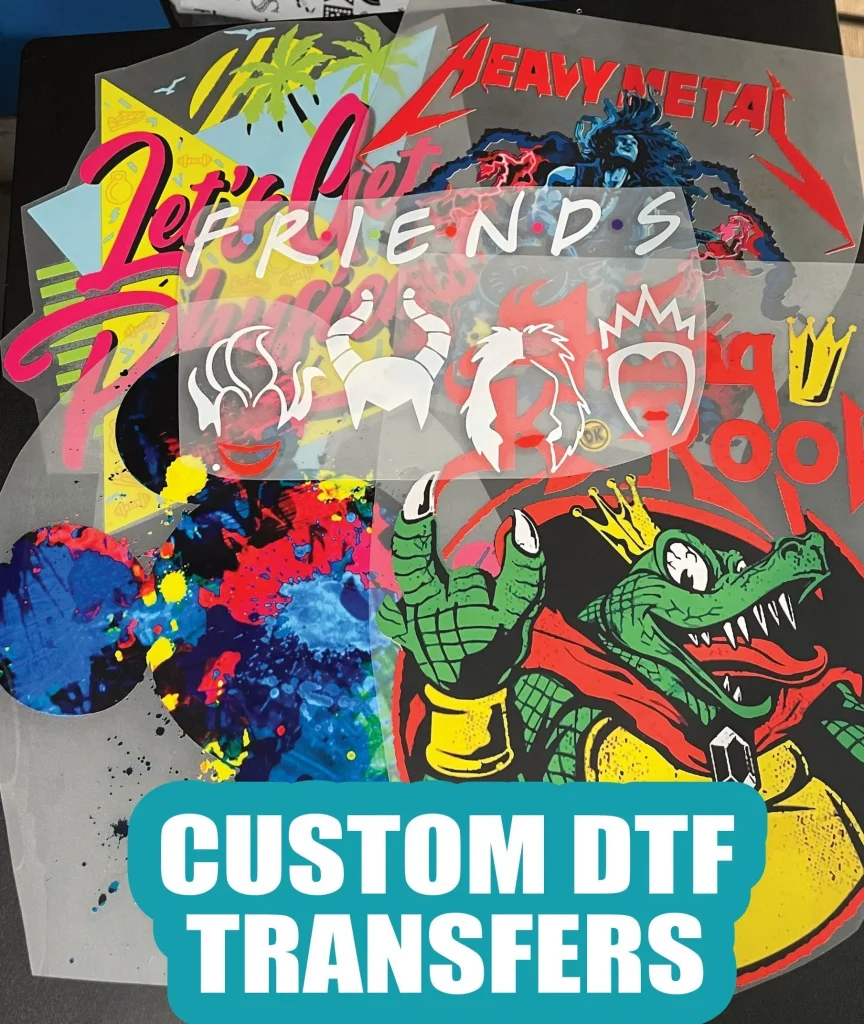

What Makes DTF Transfers Unique?

DTF Transfers, or Direct to Film transfers, stand out in the printing landscape due to their ability to produce vibrant colors and intricate designs effortlessly. This innovative print technology allows detailed graphics to be created that can seamlessly adhere to a variety of fabrics including cotton, polyester, and blends. Unlike traditional methods like screen or vinyl printing, DTF provides a more versatile approach, enabling designers to experiment with colors and patterns without worrying about the limitations of fabric types.

Furthermore, the process of applying DTF Transfers is user-friendly and efficient, reducing the time from design conception to final product. The use of a specific type of film to carry the adhesive means that businesses can work with lower inventory levels and offer customizations on-demand. As a result, the possibilities for unique apparel designs skyrocket, making DTF an attractive option for custom apparel businesses looking to elevate their offerings.

Advantages of DTF Printing Over Other Methods

When considering print technology, DTF printing offers several advantages over traditional methods such as screen printing and heat transfer vinyl. First, the durability of DTF images cannot be overstated; prints resist cracking and fading, thus maintaining the vibrancy of colors even after multiple washes. This feature is crucial for businesses that aim to sell apparel that withstands the test of time, thereby enhancing their brand reputation.

Additionally, DTF Transfers eliminate the need for high minimum order quantities, which means smaller companies can produce custom designs without a substantial financial burden. This cost-effective solution opens the doors for creative entrepreneurs who want to explore their stylish ideas without committing to large batches they might not sell. Overall, the accessibility and performance of DTF printing distinguish it as a leader in custom apparel design.

Innovations in DTF Technology

Recent innovations in DTF technology showcase how the industry evolves to meet the needs of modern businesses. Companies like Eazydtf have made significant investments in expanding the capabilities of their DTF printing technology, resulting in sharper images and richer colors. This advancement means that apparel designers can create more complex and visually stunning graphics that attract customers looking for standout pieces in their wardrobes.

Moreover, firms like Insta Graphic Systems have introduced new DTF heat transfers designed specifically for improved durability and vibrancy. These innovations not only enhance the quality of the final product but also contribute to better customer satisfaction. As DTF technology continues to advance, businesses can expect to see even more capabilities that solidify the technique as the go-to choice for custom apparel design.

Implementing DTF Transfers in Your Apparel Business

For business owners eager to incorporate DTF Transfers into their product offerings, knowing where to start is crucial. The first step is investing in quality DTF printing equipment, which includes printers optimized for printing on film as well as reliable transfer films and adhesives. Proper equipment ensures that print quality meets industry standards, paving the way for impressive end-products that catch consumers’ eyes.

Next, seeking out trustworthy suppliers of materials is essential. With reputable partners, businesses will have access to the latest innovations in DTF printing films and inks, essential for producing high-quality designs. Additionally, taking the time to learn and master the DTF transfer process will empower individuals to make the most of this versatile printing method, helping them stand out in the crowded custom apparel market.

Marketing Your DTF Custom Apparel

Once you have integrated DTF Transfers into your apparel offerings, effective marketing strategies will be vital to attracting customers. Utilizing social media platforms to showcase vibrant images of custom designs can help create buzz around new product lines. Engaging in community events or fashion shows that highlight your DTF capabilities can also enhance visibility and allow potential customers to see the quality firsthand.

Incorporating customer feedback into marketing efforts will help refine your offerings. Collecting testimonials from satisfied customers can strengthen your brand’s credibility and promote word-of-mouth marketing. By continuously interacting with your audience online and highlighting unique aspects of your DTF apparel, you can establish a dedicated customer base that appreciates your stylish, custom designs.

The Future of Custom Apparel with DTF Technology

As technology advances, the future of custom apparel seems poised for exciting transformations, particularly with DTF printing at the forefront. As businesses adopt these innovative techniques, we anticipate a shift towards greater personalization in fashion, allowing consumers to express their individuality through tailored products. The increased accessibility of DTF transfers may encourage more entrepreneurs to enter the apparel market, thus fostering a creative environment rich with unique styles.

Furthermore, the environmental impact of print technology will likely drive innovations in the DTF space, with a focus on eco-friendly materials and processes. This can resonate well with modern consumers who are increasingly aware of sustainability issues in fashion. Companies that embrace these advancements in DTF transfers while prioritizing environmentally conscious practices will likely thrive in this evolving apparel landscape.

Frequently Asked Questions

What are DTF Transfers and how do they differ from other printing methods?

DTF Transfers, or Direct to Film transfers, are a modern print technology that allows colorful, high-definition designs to be transferred onto a variety of textiles. Unlike traditional methods like screen printing or sublimation, DTF printing uses a film coated with adhesive, enabling intricate designs on fabrics such as cotton and polyester blends. This innovative approach provides a wider range of colors and exceptional detail, making it ideal for custom apparel.

What fabrics can be used with DTF printing for custom apparel?

DTF printing is highly versatile and compatible with a broad range of fabric types. You can use it efficiently on materials such as cotton, polyester, blends, and even certain synthetic fabrics. This flexibility allows businesses to offer custom apparel that meets diverse customer needs and preferences.

What are the key benefits of using DTF Transfers for custom apparel design?

The benefits of DTF Transfers include vibrant color output, intricate design capabilities, durability, and cost-effectiveness. DTF printing allows for highly detailed graphics that resist cracking and fading over time, making them ideal for frequent wear. Additionally, with no minimum order requirements, small businesses can cater to small batches or unique designs without high upfront costs.

How can I start using DTF Transfers in my apparel business?

To start using DTF Transfers, invest in a printer that supports DTF technology, along with high-quality transfer films and adhesives. Find reliable suppliers to provide quality materials and resources, practice the printing process to perfect your technique, and promote your new DTF products through marketing channels. Customer feedback will also help refine your offerings for better engagement.

Are there any recent advancements in DTF printing technology?

Yes, recent advancements in DTF printing technology have made it more accessible for small businesses. Innovations such as premium services from companies like Sam’s DTF Transfers and expanded large-format printing capabilities by Eazydtf have increased the potential for vibrant color and detail. New DTF heat transfer products are also being launched to improve durability and enhance consumer appeal.

What makes DTF Transfers a game-changer for custom apparel businesses?

DTF Transfers represent a significant evolution in print technology, offering exceptional versatility and quality for custom apparel. With their ability to produce detailed, colorful designs on various fabrics, combined with durability and cost-efficiency, DTF printing allows businesses to stand out in a competitive market while appealing to consumer demand for unique, personalized fashion.

| Key Features | Details |

|---|---|

| What is DTF Transfers? | Direct to Film (DTF) printing is a method that allows intricate designs to be transferred onto various fabrics with vibrant colors and detail utilizing a film coated with adhesive. |

| Recent Innovations | Notable advancements include services by Sam’s DTF Transfers, capabilities expansion by Eazydtf, and new product launches by Insta Graphic Systems, which are making DTF technology more accessible. |

| Advantages of DTF Printing | DTF printing offers versatility across fabric types, vibrant color options, durability against fading, and cost-efficiency with no minimum order requirements. |

| Implementation Tips | Invest in compatible equipment, find reliable suppliers, practice the process, market your offerings, and gather customer feedback to enhance your DTF printing experience. |

Summary

DTF Transfers are transforming the custom apparel market by providing businesses with innovative methods to express creativity while ensuring quality and durability. With the ability to handle a variety of fabrics and produce high-resolution designs, the DTF process stands out as a practical solution for modern garment decoration. As technology continues to evolve, so too does the efficiency and effectiveness of DTF printing, making it an appealing choice for entrepreneurs and established businesses alike. Companies that adopt DTF Transfers benefit from lower production costs, enhanced design capabilities, and ultimately, a better connection with their target audience, embodying the next generation of apparel customization.