In the dynamic realm of modern printing, DTF transfers have emerged as a remarkable eco-friendly alternative that businesses should consider. This innovative Direct-to-Film (DTF) printing technique utilizes water-based inks, contributing to a more sustainable printing process compared to traditional methods. DTF transfers not only reduce waste but also enable a diverse range of fabric applications, effectively meeting the needs of environmentally conscientious consumers. As advancements in printing technology continue to unfold, the appeal of DTF transfers grows stronger, offering a powerful solution for brands prioritizing sustainability. Join us as we delve into the world of DTF printing and explore its numerous benefits that align with eco-friendly printing practices.

Also referred to as direct-to-film printing, DTF transfers denote a cutting-edge approach to textile printing that emphasizes sustainability and resource efficiency. This technique leverages innovative printing technologies to achieve vibrant and durable designs on various materials, while maintaining a commitment to eco-friendly standards. By harnessing water-based inks and reducing waste production, this method presents a compelling option for eco-conscious brands looking to enhance their product offerings. As the printing industry evolves, the importance of such sustainable practices becomes increasingly vital for businesses aiming to minimize their environmental impact. In this discussion, we highlight the advantages of using DTF transfers and their role in shaping the future of sustainable printing.

Understanding the DTF Printing Technique

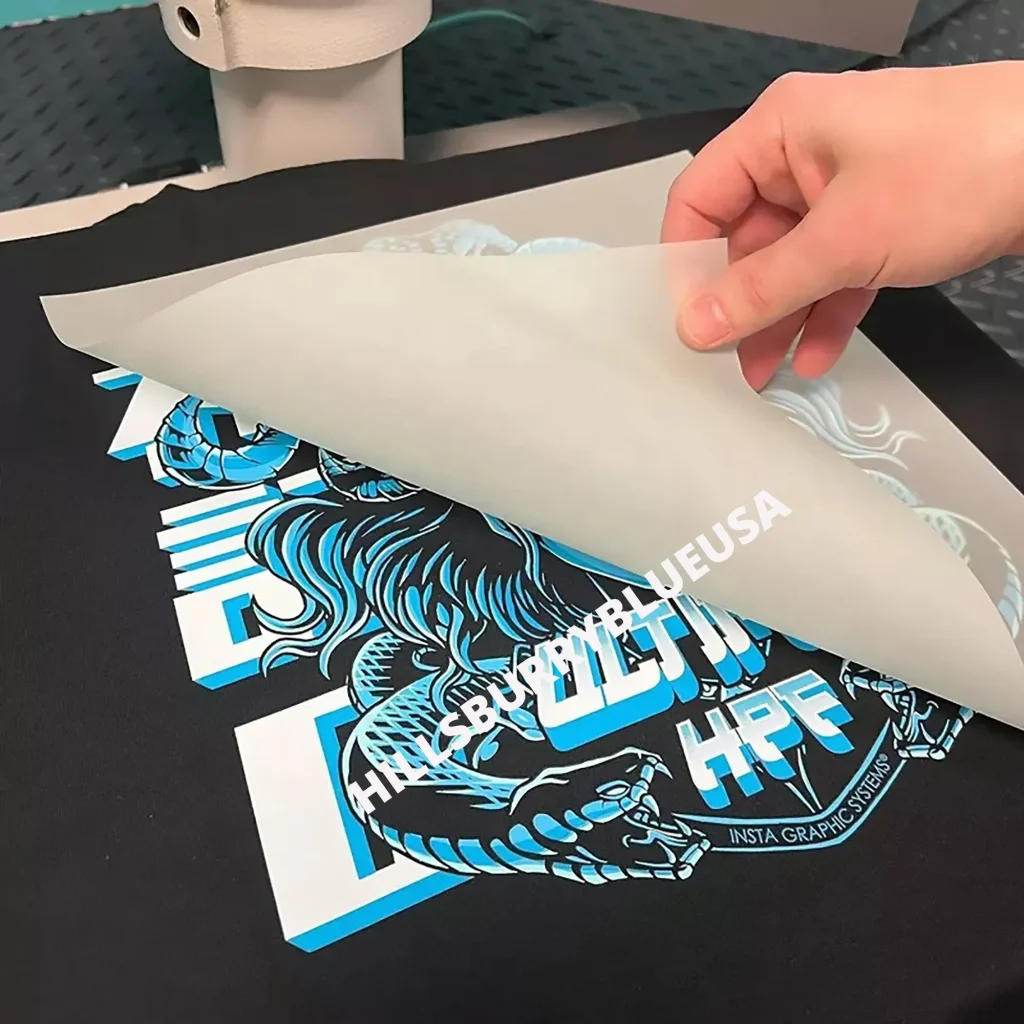

Direct-to-Film (DTF) printing has emerged as a groundbreaking technique offering numerous advantages for modern print businesses. This method revolutionizes how designs are applied to fabrics, allowing for easy transfer of vibrant colors and intricate graphics. Unlike traditional printing methods that may involve extensive setup and resources, DTF printing simplifies the process by using specially coated films to achieve high-quality results without the waste associated with excess inks or materials.

The DTF process begins with the creation of a digital design, which is then printed onto a transfer film. After applying a hot-melt adhesive powder, the film is ready to be transferred to various fabrics using heat. This unique approach not only ensures durability and versatility but also supports eco-friendly initiatives by minimizing material waste and reducing harmful emissions, making it an attractive choice for sustainable printing efforts.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, use a specialized printing technique to apply designs on a film that can be transferred to various fabrics using heat. This process involves printing a design on a film, applying a hot-melt adhesive, and then using heat to transfer the design onto textiles. The versatility and efficiency of this process enhance its appeal in eco-friendly printing.

How are DTF Transfers environmentally friendly?

DTF transfers are considered eco-friendly due to reduced waste, the use of water-based inks, and energy-efficient processes. By minimizing leftover materials and harmful VOC emissions associated with solvent-based inks, DTF printing helps lower the ecological footprint while delivering high-quality designs.

What advantages do water-based inks provide in DTF printing?

Water-based inks used in DTF printing are far more sustainable than traditional solvent-based inks. They reduce harmful volatile organic compound (VOC) emissions, making DTF transfers safer for both the environment and the workers involved in the printing process, thus aligning with the principles of sustainable printing.

Can DTF Transfers be applied to different fabric types?

Yes, DTF transfers are extremely versatile and can be used on a variety of fabrics, including cotton, polyester, and fabric blends. This adaptability reduces the need for multiple printing technologies, further promoting an eco-friendly approach to printing.

What recent advancements have been made in DTF printing technology?

Recent advancements in DTF printing technology include improvements in print quality and durability. These enhancements allow businesses to embrace DTF transfers as an effective means of achieving sustainability and high-quality results without compromising efficiency, reflecting ongoing innovations in printing technology.

Why is energy efficiency important in DTF printing?

Energy efficiency in DTF printing is crucial as it reduces overall energy consumption and carbon emissions. The DTF printing process requires less heat and shorter processing times compared to traditional printing methods, contributing to a lower operational carbon footprint and promoting eco-friendly practices in the industry.

| Key Point | Description |

|---|---|

| DTF Transfers | A modern printing technique that transfers designs onto fabrics using a special film and adhesive. |

| Eco-Friendly Advantages | Includes reduced waste, use of water-based inks, versatility in fabric types, and energy efficiency. |

| Recent Developments | Continuous advancements in technology which enhance print quality; increasing adoption by eco-conscious brands. |

| Considerations for Use | Importance of selecting environmentally compliant inks and adhesives for sustainable practices. |

Summary

DTF Transfers are revolutionizing the printing industry as an eco-friendly option that emphasizes sustainability and versatility. This innovative printing method minimizes waste, utilizes water-based inks, and adapts to various fabric types, appealing to businesses committed to reducing their environmental impact. As advancements in DTF technology continue to emerge, its widespread acceptance among brands focused on sustainability is also growing. By implementing DTF Transfers, companies not only enhance their product offerings but also contribute to a greener future, highlighting their dedication to eco-friendly practices.