DTF Transfers, or Direct-to-Film printing, is revolutionizing the apparel printing industry with its innovative approach to design transfer. This method stands out among traditional techniques such as Direct-to-Garment (DTG) and screen printing, offering a unique blend of efficiency and versatility that businesses can leverage. As the demand for high-quality, durable prints increases, DTF printing provides exceptional results on a variety of fabric types, including cotton and polyester, catering to diverse market needs. Moreover, it addresses modern sustainability concerns, significantly reducing waste output and aligning with eco-friendly practices. In this detailed exploration, we will dive deeper into DTF Transfers, assessing its benefits and comparing it against other popular printing methods.

Referred to by various names such as Direct-to-Film printing and innovative fabric transfer techniques, DTF Transfers are making significant waves in the garment decoration sector. This cutting-edge approach is reshaping how businesses think about printing options, distinguishing itself from established methods like Direct-to-Garment and conventional screen printing. With an increasing focus on sustainable printing solutions, DTF technology not only delivers high-quality results but also minimizes waste, making it an attractive choice for eco-conscious brands. As we analyze the advantages of DTF and how it squares off against other printing methods, it becomes evident that this technique is opening up new avenues for creativity and operational efficiency in the printing landscape.

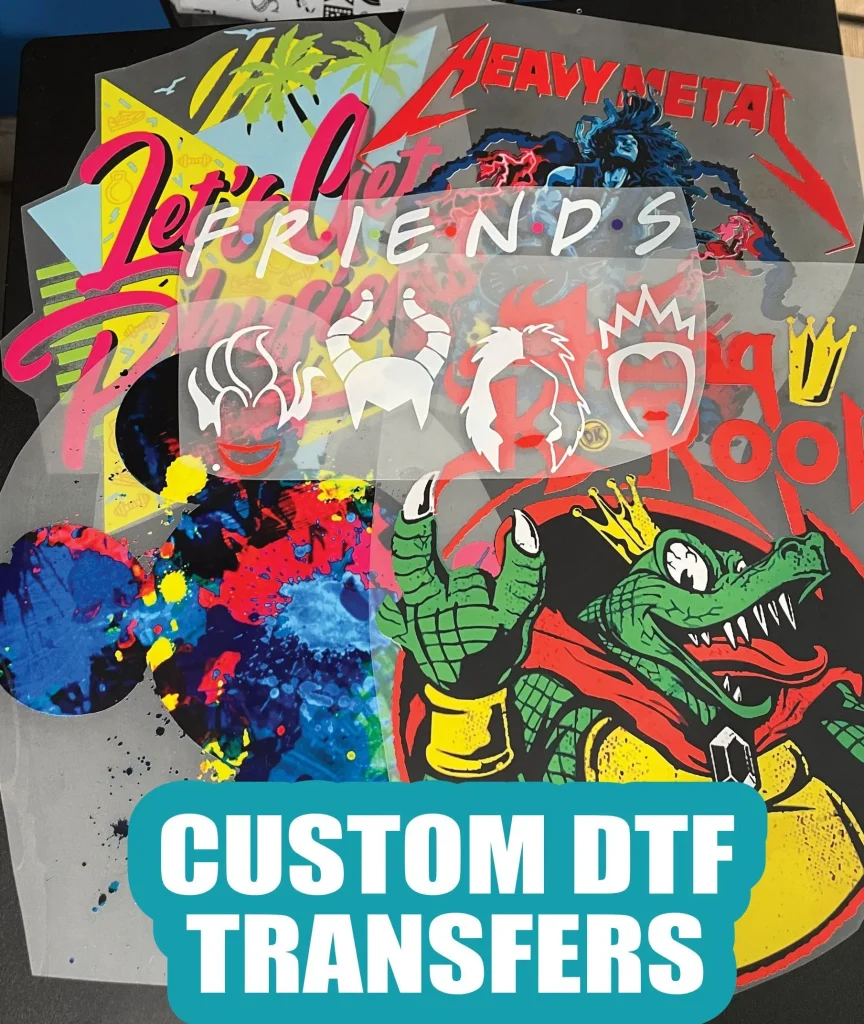

Exploring the Mechanisms of DTF Printing

Direct-to-Film (DTF) printing is a method designed to create high-quality transfers for printing on fabrics. By utilizing advanced technology, DTF allows designs to be printed onto a special film, which is then heat-pressed onto the fabric. This process provides a vibrant finish, with a soft hand feel that remains breathable. The versatility of DTF makes it optimal for varying fabric types, such as cotton, polyester, and blends, hence broadening your design possibilities and expanding market reach.

Moreover, one significant aspect of DTF printing is its ability to replicate intricate designs with precision. Whether you are creating detailed graphics or complex text, DTF technology ensures that every element of your design is captured in clarity and color fidelity. This attribute sets DTF apart from more traditional methods, such as screen printing, where achieving fine details can be challenging and time-consuming. As a growing technology, DTF presents a compelling case for those looking to produce high-quality prints efficiently.

Advantages of DTF Transfers Over Traditional Methods

When comparing DTF transfers to more traditional printing methods like Direct-to-Garment (DTG) and screen printing, several key advantages stand out. For starters, DTF printing enables quick setup times and shorter production runs, making it an attractive option for custom orders and smaller businesses. In contrast, screen printing often requires extensive preparation, making it less favorable for small-scale projects. With DTF, the ease of use translates to increased production efficiency, allowing businesses to respond swiftly to customer demands.

Additionally, DTF printing is economical for high-volume productions. Unlike DTG, which can accumulate high ink and maintenance costs, DTF technology is designed to lower operational costs while maintaining quality. The ability to print vibrant colors on dark fabrics without requiring pretreatments showcases DTF’s efficiency. As sustainability becomes increasingly relevant in modern merchandising, DTF’s reduction in material waste and eco-friendly production practices further solidify its position as a superior choice.

The Eco-Friendly Nature of DTF Printing

Sustainable printing practices have surged in importance as businesses strive to minimize their carbon footprint. DTF printing exemplifies this approach by reducing waste and promoting eco-friendly materials throughout the printing process. Unlike traditional screen printing, which often entails chemical-laden inks and treats, DTF uses water-based inks, aligning better with sustainable practices. This choice not only enhances the environmental outlook but also appeals to the growing demographic of eco-conscious consumers.

Furthermore, DTF’s efficient material use means less ink is wasted, creating a more sustainable production cycle. By capitalizing on techniques that minimize waste, businesses not only save costs but also demonstrate a commitment to environmental stewardship. This focus on sustainability resonates well with today’s consumers who increasingly favor brands that prioritize eco-friendly practices in their product sourcing and manufacturing processes.

DTF Transfers: A Versatile Solution for Businesses

DTF transfers are versatile, making them suitable for a broad range of applications in the apparel industry. From custom t-shirts to promotional merchandise, DTF printing can accommodate various designs, sizes, and fabric types. This adaptability is instrumental for businesses aiming to cater to diverse customer preferences and seasonal trends. Furthermore, the ability to print on both light and dark fabrics without additional steps places DTF ahead in the competition.

As consumer demand continues to evolve, versatility in product offerings becomes a significant advantage. Businesses utilizing DTF printing can quickly pivot between designs and fulfill varying order sizes without extensive lead times. This capability not only boosts customer satisfaction but also positions companies to capitalize on the trending market shifts efficiently. By embracing DTF technology, businesses can ensure they remain responsive and agile in an interconnected marketplace.

DTF Printing vs. Screen Printing: A Comparative Analysis

While screen printing has long been a staple in the garment printing industry, DTF printing offers clear benefits that merit serious consideration. One of the main distinctions between these methodologies is setup and production time. Screen printing’s labor-intensive setup makes it less viable for smaller orders; however, DTF requires minimal initial adjustments, allowing for rapid processing of custom designs. This efficiency translates to faster turnaround times for consumers and increased profitability for businesses.

In terms of print quality, DTF can produce sharp, intricate designs with a soft-touch feel on fabrics, ingraining it deeper into the textile than typical screen prints. This feature enhances garment longevity while delivering vibrant colors not easily replicated by conventional screen printing methods. For businesses aiming to deliver high-quality products swiftly, understanding these differences is pivotal when choosing the correct method for their printing needs.

Future Trends in DTF Printing Technology

As the landscape of printing technology continues to evolve, DTF printing stands at the forefront of innovation. With advancements in the equipment and materials used, future iterations of DTF printing are expected to enhance capabilities, including increased speed and improved sustainability features. As manufacturers innovate, DTF printing will likely incorporate more eco-friendly and cost-effective inks, appealing to businesses striving for an environmentally responsible approach in their production.”},{

Moreover, the integration of advanced digital technologies, such as artificial intelligence and automated systems, may redefine application techniques in DTF printing. These enhancements could allow businesses to achieve unprecedented levels of detail and customization. As consumers demand more personalized experiences, DTF printing is poised to meet these expectations efficiently, setting new benchmarks for quality and operational excellence in the printing industry.

Frequently Asked Questions

What are DTF Transfers and how do they work?

Direct-to-Film (DTF) Transfers are a modern printing method that involves printing designs onto a special film, which is then heat-transferred to fabric. This innovative technique is designed to work on various materials, including cotton and polyester, providing vibrant and durable prints.

How does DTF printing compare to Direct-to-Garment printing?

DTF printing offers greater fabric compatibility compared to Direct-to-Garment (DTG) printing, which is mainly effective on cotton. DTF is more economical for larger production runs and allows for faster setup and printing times, making it ideal for custom orders.

Is DTF printing more sustainable than traditional screen printing?

Yes, DTF printing is often considered more sustainable than traditional screen printing because it generates less waste and uses fewer resources. This eco-friendly approach aligns well with the growing demand for sustainable printing practices in the industry.

What are the advantages of using DTF Transfers for small businesses?

DTF Transfers provide small businesses with unparalleled flexibility, allowing them to produce high-quality prints on various fabric types without extensive setup. This method is cost-effective for small runs and custom orders, which is essential for niche markets.

Can DTF Transfers achieve intricate designs better than screen printing?

Absolutely! DTF Transfers excel at producing intricate designs with vibrant colors and softer finishes, making them a superior choice compared to screen printing, which may not capture fine details or complex color gradients as effectively.

What should I consider when choosing between DTF printing and other methods?

When deciding on a printing method, consider factors such as your target market, the types of garments you print, budget constraints, and the desired turnaround time. DTF printing is an excellent choice for businesses seeking versatility and quick responses to varying customer demands.

| Comparison Aspect | DTF Printing | Direct-to-Garment (DTG) | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | Works on various fabrics (cotton, polyester, dark textiles) | Best for cotton and lighter fabrics | Most cost-effective for large runs only |

| Cost | More economical for high-volume production | Higher ink costs and maintenance | Cost-effective for bulk due to setup costs |

| Speed & Flexibility | Faster production times for large orders | Slower due to setup time | Long setup, effective for bulk only |

| Print Quality | Supports high-resolution, vibrant colors | High quality but limited to fabric types | Durable prints but less vibrant for complex designs |

Summary

DTF Transfers are revolutionizing the apparel printing sector by offering a hybrid of efficiency, versatility, and eco-friendliness that traditional methods like Direct-to-Garment and screen printing often fail to match. This innovative printing technology is quickly becoming the go-to choice for both small businesses and larger manufacturers, thanks to its ability to handle a variety of fabric types while delivering high-quality designs. As consumer preferences increasingly shift towards sustainable practices, DTF’s minimal waste production aligns seamlessly with this demand, making it not only a practical printing solution but also an environmentally responsible option. By exploring the benefits and applications of DTF Transfers, businesses can optimize their operations and stay competitive in a rapidly evolving market.