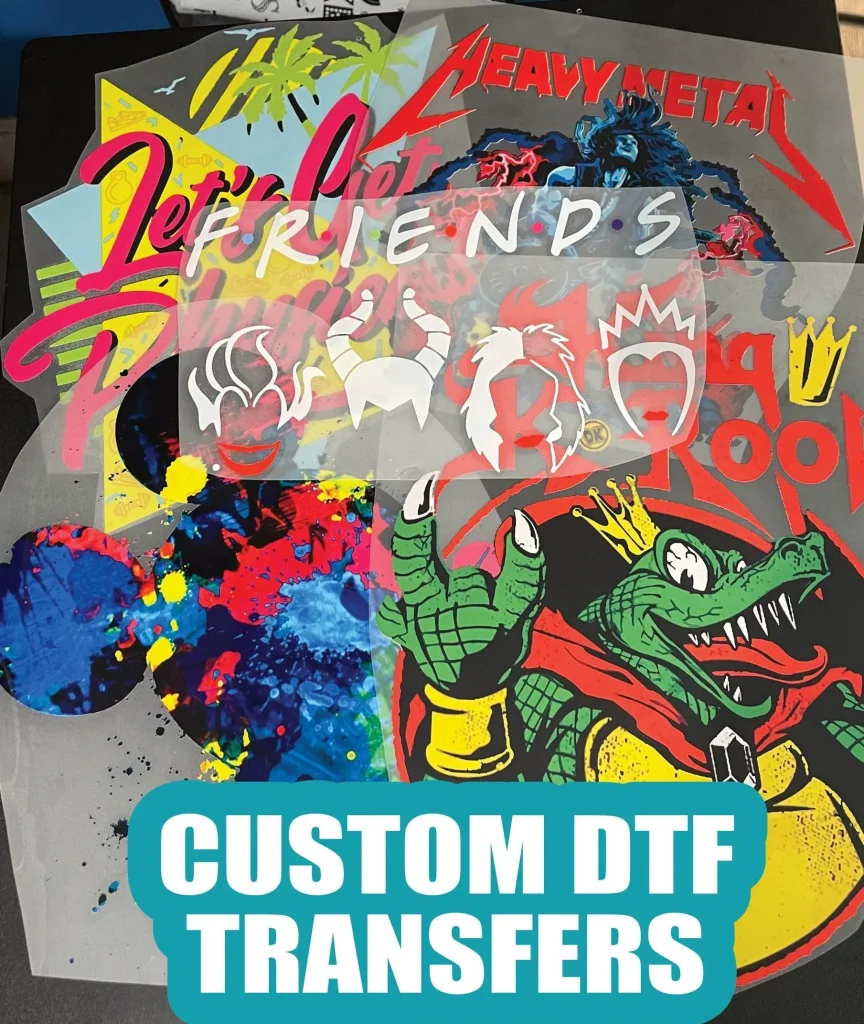

In the vibrant domain of custom apparel printing, DTF transfers (Direct-to-Film transfers) are gaining momentum, distinguished by their ability to deliver stunning graphics with unparalleled durability. Whether you’re a seasoned printer or a novice eager to explore new avenues, understanding the DTF transfer process is essential for maximizing your creative potential. This innovative printing technique utilizes advanced DTF printing technology, allowing for high-quality designs to be printed on specialized film and easily transferred onto various fabrics. By harnessing the power of gang sheets, users can optimize their print production while ensuring vivid results that captivate customers. As we dive deeper into the intricacies of DTF transfers, this guide will equip you with the essential knowledge needed to embark on your custom apparel journey with confidence.

As you navigate the ever-evolving landscape of apparel design, you’ll come across various terms like direct-to-film application, film transfer printing, and even ink transfer processes that all relate to the process of DTF transfers. These innovative techniques provide creative individuals with the tools they need to bring custom designs to life on fabric. The comparison between sublimation vs. DTF illustrates the breadth of choices available, influencing decisions based on the type of materials you wish to print on. Utilizing techniques such as gang sheets can enhance efficiency and reduce waste in production, making it an attractive option for many printers. This guide focuses on demystifying DTF printing and related concepts, guiding you in selecting the right equipment and approaches for a successful venture into custom apparel printing.

Understanding the DTF Transfer Process in Depth

The DTF transfer process involves several crucial steps that ensure high-quality prints on various fabrics. First, you begin with design creation, where you can utilize graphic design software to craft your artistic visions. It’s essential to consider the specifications for print size and resolution at this stage, as high-quality designs will significantly impact your final product. Once your design is ready, it is printed onto a special DTF film using a printer specifically designed for this printing technique, utilizing special inks that guarantee vibrant results.

Following the printing, the adhesive powder is applied to the design, bonding the inks and allowing for a successful transfer to fabric. Curing the film with heat is the next critical step, activating the adhesive and ensuring the printed design will adhere correctly during the heat transfer process. Finally, when applying the DTF transfer using a heat press, adhering to the recommended temperature and time guidelines is imperative to achieving the best possible result with durable prints that can withstand multiple washes.

The Versatility of DTF Transfers for Custom Apparel

One undeniable advantage of DTF printing is its adaptability across various textile types. Whether you’re working with cotton, polyester, or fabric blends, DTF transfers provide exceptional quality and durability. For instance, when applied to cotton garments such as T-shirts and hoodies, DTF yields vibrant, wash-resistant designs that can elevate any custom apparel project. This versatility makes DTF a favored choice among businesses looking to diversify their product offerings while maintaining high print fidelity.

Additionally, compared to other printing methods—such as sublimation, which is limited to light-colored polyester—DTF facilitates the creation of striking graphics on dark fabrics. This unique capability allows for creative freedom, enabling businesses to cater to a broad audience with varying preferences. As such, the market for custom apparel leveraging DTF technology continues to expand, highlighting its potential for growth in the custom printing industry.

Key Trends and Innovations in DTF Printing Industry

In the ever-evolving world of custom apparel printing, staying updated on the latest trends and innovations in DTF (Direct-to-Film) technology is vital for both hobbyists and businesses. One key trend is the growing popularity of gang sheets, where multiple designs are printed on a single sheet of film. This efficient practice optimizes resource use, enabling businesses to minimize costs while maximizing output. Utilizing gang sheets allows companies to increase their productivity, making DTF printing not only cost-effective but also time-efficient.

Another notable innovation is the emergence of large-scale DTF printing services, exemplified by Eazydtf’s expansion efforts. By investing in advanced printing technology and offering same-day shipping, they enhance customer satisfaction and streamline operations. Such developments not only reflect the rising demand for DTF transfers but also the industry’s commitment to improving accessibility and efficiency for businesses at all scales.

Choosing the Right Equipment for DTF Printing Success

To achieve the best results with DTF printing, selecting the right equipment is paramount. First and foremost, investing in a quality DTF printer designed specifically for this process is crucial. These printers utilize specific inks that ensure high-resolution prints capable of vibrant colors and intricate details. As you navigate the variety of options available, consider factors like printer speed and print quality to find a model that fits your needs.

Equally important is acquiring a dependable heat press machine, as this piece of equipment is essential for transferring the designs onto fabric. Look for heat presses that offer adjustable pressure and temperature settings, as different materials may require varying heat applications. Pairing your printer with a high-quality heat press will significantly improve the outcome of your custom apparel projects, ensuring that each transfer is accurately and evenly applied.

Comparative Insights: Sublimation vs. DTF Printing

When exploring the dynamic realm of custom printing, understanding the differences between sublimation and DTF printing is crucial for making informed choices. While sublimation works best on light-colored, polyester fabrics, DTF printing’s versatility allows for vibrant designs on both light and dark materials. This capability opens the door for diverse applications and customer preferences, positioning DTF as an attractive option for those wanting to print on various fabric types.

Another key difference lies in the application processes. Sublimation involves converting ink into gas, which then infuses into the fabric—a technique best suited for garments that remain light-colored. Conversely, DTF printing involves applying a transfer film and adhesive, which adheres firmly to the material when heat-pressed. Understanding these nuances helps in selecting the optimal printing technology for your specific projects, allowing you to cater better to customer needs.

Future Prospects of DTF Transfers in Custom Apparel Business

As the custom apparel industry continues to innovate, DTF transfers are poised to play a pivotal role in shaping the future of printing. The accessibility of DTF technology—combined with advances in equipment and materials—makes it an exciting option compared to traditional methods. With increased consumer demand for personalized and unique apparel, businesses that leverage DTF transfers could see significant growth opportunities. The versatility of this printing method enables creators to explore new design possibilities while maintaining high quality and durability.

Moreover, as more companies invest in DTF printing technology, the potential for new applications and services will expand. High-volume printing capabilities, as seen with businesses like Snuggle, which manages up to 15,000 prints daily, exemplify how DTF can streamline large-scale operations. Such innovations suggest that the future of DTF transfers will not only cater to burgeoning demand but may also lead to further adaptations in printing technology, enhancing the overall landscape of custom apparel.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a innovative custom apparel printing technique that involves printing designs onto a special film. This film is then transferred onto garments using heat. DTF transfers are noted for their vibrant colors and durability on various fabric types, making them a popular choice for custom apparel.

What are gang sheets in DTF transfers, and how can they benefit my printing process?

Gang sheets in DTF transfers refer to the practice of printing multiple designs on a single sheet of transfer film. This technique maximizes material usage and can significantly reduce costs by allowing more prints per sheet. Utilizing gang sheets not only improves efficiency but also enhances productivity in custom apparel printing.

How does sublimation compare to DTF printing for custom apparel?

When comparing sublimation vs DTF printing, it is essential to note that DTF is ideal for dark fabrics, while sublimation works best on light-colored polyester materials. Each method serves different needs in the custom apparel industry; choose DTF for versatility across a range of fabric types.

What essential equipment do I need to start DTF printing?

To get started with DTF printing, you’ll need a specialized DTF printer, a reliable heat press machine for transferring designs, and DTF compatible films and inks. This equipment is crucial for ensuring high-quality outputs and successful application of DTF transfers.

What steps are involved in the DTF transfer process?

The DTF transfer process involves several key steps: creating your design, printing it on transfer film, applying adhesive powder, curing the transfer with heat, and finally using a heat press to transfer the design onto your garment. Each step is vital for achieving vibrant and durable DTF prints.

What types of fabrics work best with DTF transfers?

DTF transfers are versatile and can be used on various fabrics such as cotton, polyester, and fabric blends. This adaptability makes DTF printing a suitable choice for a wide range of custom apparel items, including T-shirts, hoodies, and sportswear.

| Key Aspect | Description |

|---|---|

| What is DTF Printing? | A method where designs are printed on special film and transferred to garments using heat. It allows for high-resolution prints on various fabrics. |

| Gang Sheets | A technique of printing multiple designs on one sheet to optimize material and reduce costs, allowing for efficient printing. |

| Sublimation vs. DTF | DTF works best on dark fabrics, while sublimation is suited for light-colored polyester fabrics. Understanding both helps in choosing the right method. |

| Investment and Expansion | Eazydtf’s major investment in DTF technology allows for same-day shipping, enhancing customer experiences with quick services. |

| New Trade Services | Snuggle’s trade services can handle up to 15,000 DTF prints daily, ideal for businesses needing high-volume printing. |

| Essential Equipment | Includes a DTF printer, heat press, and DTF-specific inks and films for achieving high-quality prints. |

| DTF Transfer Process | Involves design creation, printing on film, applying adhesive, curing transfers, and heat pressing onto garments. |

| Applications | DTF transfers work well on cotton, polyester, and blends, making them versatile for various apparel types. |

Summary

DTF Transfers present a remarkable avenue for anyone venturing into custom apparel printing. This technology offers a unique combination of design versatility, quality, and an easy-to-learn process, making it ideal for both hobbyists and professionals. As you explore this innovative printing method, understanding the essentials, including the necessary equipment and the transfer process, is crucial for success. With continuous advancements in DTF technology, aspiring entrepreneurs can harness this opportunity to create stunning apparel designs and thrive in the custom printing industry. Embracing DTF Transfers could be your key to unlocking a creative and profitable enterprise!