In the exciting realm of custom garment printing, the **DTF Gangsheet Builder** stands out as a game-changing tool for designers and businesses alike. This innovative platform allows users to create stunning, vibrant designs that can be printed directly onto fabrics with unparalleled efficiency. By simplifying the gangsheet printing process, the DTF Gangsheet Builder not only maximizes productivity but also ensures each print showcases the brilliance of direct-to-film printing technology. Whether you’re crafting intricate fabric designs or scaling up your production for bulk orders, this builder streamlines the workflow, offering an ideal solution for diverse printing needs. In this guide, we will explore the ins and outs of using the DTF Gangsheet Builder to achieve eye-catching results in your fabric design projects.

When it comes to fabric printing, utilizing advanced tools like the DTF Gangsheet Builder can significantly enhance your creative output. Also known as direct-to-film printing, this technique involves printing intricate designs onto a film before transferring them to fabric, making it a popular choice for custom garment printing. The gangsheet method allows multiple designs to be printed simultaneously, maximizing efficiency while delivering quality results on various materials. With the right setup and an understanding of the printing process, you can create eye-catching pieces that stand out in the garment industry. Dive into the world of DTF printing and discover the powerful capabilities of the Gangsheet Builder for your next fabric design project.

Understanding the Basics of DTF Printing

**Direct-to-Film (DTF) printing** is a revolutionary process that simplifies the garment printing experience. Unlike traditional methods, DTF printing allows designers to transfer intricate graphics onto various materials, including cotton and polyester. This method is particularly beneficial for small businesses that aim to provide unique and personalized apparel with vibrant colors and high detail. The DTF printing process works by printing designs onto a special film, which is then heat pressed onto the fabric, ensuring durability and vividness.

The flexibility of DTF printing extends to its compatibility with a range of fabrics, making it a versatile choice for custom garment printing. Users can achieve stunning visual effects with minimal effort, thus maximizing their production efficiency. As businesses look for innovative ways to engage their customers, understanding DTF printing’s nuances becomes essential for anyone looking to stay competitive in the textile market.

Key Features of the DTF Gangsheet Builder

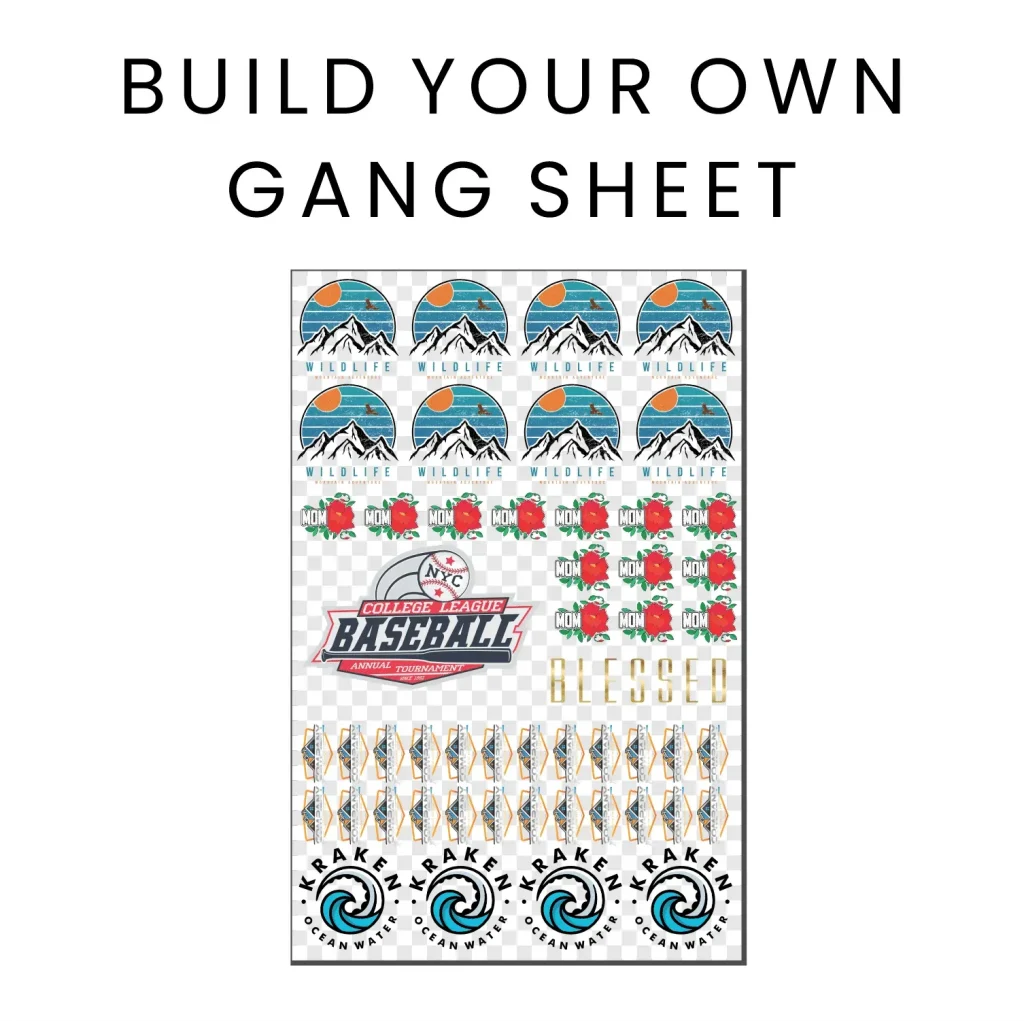

The **DTF Gangsheet Builder** is embedded with features designed to optimize the printing process, making it a must-have tool for anyone in the garment printing field. It offers an intuitive user interface that allows users to easily upload and arrange designs on a single sheet. This capability not only conserves material but also streamlines the printing workflow by reducing the number of passes needed, thereby enhancing productivity.

Another standout feature of the DTF Gangsheet Builder is its flexibility in adjusting color settings and image resolutions. Users can fine-tune their designs to match specific fabric types, which is critical for achieving the best print quality. This precision ensures that colors remain vibrant and designs as detailed as intended, allowing for an impressive output that meets customer expectations.

Maximizing Efficiency with Gangsheet Printing Techniques

Gangsheet printing allows users to print multiple designs simultaneously, significantly improving efficiency for custom garment printing. By strategically arranging designs on a single DTF film, users can minimize waste and achieve higher output rates without compromising quality. This method is particularly beneficial for businesses dealing with bulk orders, where time and material resources need careful management.

Optimizing your gang sheet layout involves considering spacing between designs to prevent overlap during the transfer process. With the right settings and proper arrangement, users can create dynamic patterns that not only save resources but also maximize visual appeal. The end result is a fabric design that stands out, showcasing the unique creativity that DTF printing permits.

Preparing Your Designs for DTF Printing

To achieve the best results from the DTF Gangsheet Builder, it is essential to prepare your designs meticulously. This includes selecting high-resolution images and ensuring that they are suitable for printing. Many users overlook the importance of DPI; however, ensuring images are set to 300 DPI will greatly impact the vibrancy and clarity of the final print on fabric. Color calibration is also a crucial aspect of this preparation, as different printers may display colors differently.

In addition, understanding how your designs interact with various fabrics can lead to improved outcomes. Testing your prints on similar materials before the final run can help identify flaws or adjustments needed for optimal results. This careful preparation phase is what differentiates high-quality prints from subpar ones, making it a critical step in utilizing the DTF Gangsheet Builder effectively.

Exploring the Benefits of DTF Printing for Business

The rise of **DTF printing** in the custom garment sector presents numerous benefits for business owners looking to diversify their offerings. One of the most notable advantages is the ability to produce vibrant and intricate designs that could easily attract customers. With DTF printing, businesses can create personalized garments on demand, catering to the growing trend of customization in fashion.

Furthermore, the overall cost-effectiveness of DTF printing streamlines operations for small businesses. By reducing the amount of material wasted and facilitating faster production processes, companies can enhance their profitability while still offering high-quality products. These aspects foster a more sustainable business model in a competitive market, aligning with consumer preferences and trends.

Staying Competitive with DTF Printing Trends

As the DTF printing landscape evolves, keeping abreast of emerging trends is vital for maintaining competitiveness in the custom garment industry. With the growing demand for personalized products, businesses that leverage DTF printing can position themselves as industry leaders. Social media platforms serve as excellent venues for showcasing unique designs and attracting potential customers, making an online presence crucial.

Additionally, participating in industry events and utilizing online communities can help businesses network and share best practices in DTF printing. Staying informed about technological advancements and market shifts allows businesses to adapt quickly, ensuring they provide the latest styles and offerings that align with consumer interests and demands.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a software tool used in DTF printing that allows users to design and arrange multiple graphics on a single film sheet. It streamlines the print process by enabling efficient use of space, which is essential in custom garment printing, helping businesses maximize productivity and minimize costs.

How do I optimize my designs using the DTF Gangsheet Builder?

To optimize your designs with the DTF Gangsheet Builder, ensure to set your canvas accurately, arrange your designs closely without overlapping, and use high-resolution images. Adjust your color settings to match your printer’s capabilities to ensure vibrant results when applying designs to fabric.

What materials are best for DTF printing with the Gangsheet Builder?

For best results using the DTF Gangsheet Builder, opt for high-quality DTF transfer films and inks. The choice of materials directly impacts the vibrancy, durability, and overall quality of your prints on various fabrics.

How can I ensure the quality of my prints with the DTF Gangsheet Builder?

Quality assurance in prints made with the DTF Gangsheet Builder involves using compatible printers, maintaining your equipment regularly, and conducting test prints before finalizing designs. This approach helps identify potential issues before production.

Is DTF printing suitable for all types of fabric designs?

Yes, DTF printing is versatile and can be used effectively on a variety of fabrics, including cotton, polyester, and blends. The DTF Gangsheet Builder allows you to create vibrant designs suitable for different garment types, making it an excellent choice for custom fabric design.

How does DTF printing compare to other garment printing methods?

DTF printing offers advantages over other methods like screen printing and heat transfer due to its ability to produce intricate designs with bright colors quickly and efficiently. The DTF Gangsheet Builder enhances this process by allowing multiple designs on one sheet, saving time and resources in custom garment printing.

| Step | Action | Details |

|---|---|---|

| 1 | Set Up Your Canvas | Open the DTF Gangsheet Builder, select canvas size for your project. |

Summary

The DTF Gangsheet Builder is a cutting-edge tool designed for efficient fabric printing, enabling users to create stunning designs with ease. By following the essential steps detailed in this guide, you’ll leverage the builder’s features to produce high-quality prints that stand out in the competitive world of garment printing. Key factors such as layout optimization, color settings, and material quality contribute to impressive results. For anyone looking to enhance their fabric printing skills, the DTF Gangsheet Builder is a must-have resource. Start your journey in creating captivating designs with unparalleled efficiency!