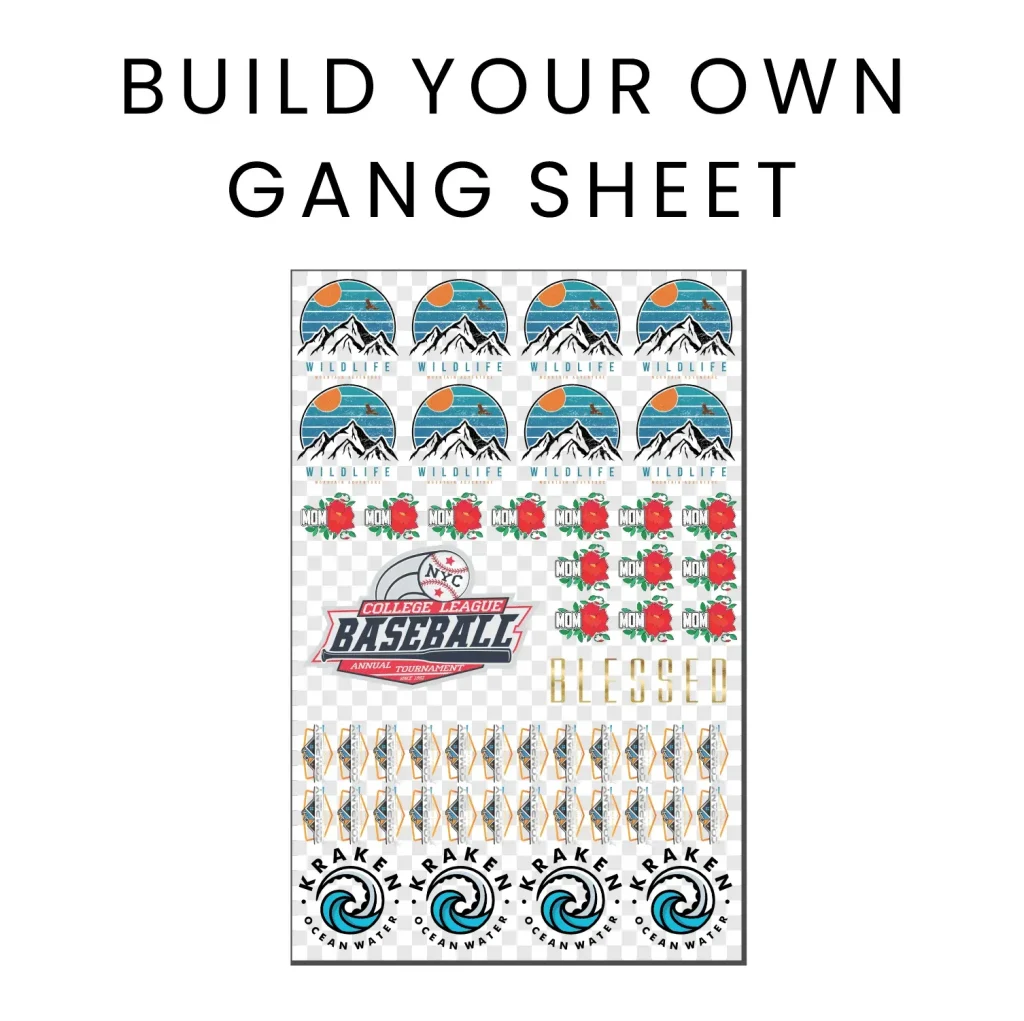

DTF gangsheet builder reshapes how studios plan and print multiple designs on transfer sheets, delivering faster setup, reduced waste, and more consistent results across hundreds of transfers per day, whether you run a cozy shop or a bustling production floor, enabling scalable growth without sacrificing color fidelity or reliability; this seamless scalability is particularly valuable for teams deploying new designs across multiple garment families. Its DTF printing gang sheet software integration lets teams automate sheet generation from a design library, implement batch operations, and enforce consistent color handling across jobs, dramatically reducing manual steps and ensuring repeatable results; workflows can be customized by user roles, and assets are versioned to keep teams aligned. This capability complements your existing DTF garment printing software stack, aligning asset management, file export formats, and printer compatibility so you can move from design to production with minimal rework. As a gangsheet design tool for DTF, it offers intelligent layout planning, collision detection, bleed margins, and per-design color options to minimize errors and help operators maximize transfer yield; it also scales across diverse teams, from design studios to large print houses, with cloud or local deployment options. Beyond these essentials, DTF workflow optimization tools monitor throughput, color consistency, and material waste, and integrate smoothly with your broader DTF ecosystem to support faster turnarounds, more efficient production, and happier customers.

In broader terms, teams seeking efficient transfer printing workflows often talk about transfer sheet planning platforms, sheet nesting software, and color-safe output engines that serve the same end goal across multiple garments. These systems act as production hubs, harmonizing templates, color profiles, asset libraries, and printer settings while integrating with RIP software and shop management ecosystems. From an LS I perspective, semantic associations around color management, asset management, collaboration, and scalable production help search engines and users recognize the topic as a cohesive, repeatable process for apparel decoration.

Key DTF gangsheet builder features for efficient production

DTF gangsheet builder features vary, but leading tools combine an intuitive grid-based workspace with drag-and-drop placement, built-in templates for standard sheet sizes, visible rulers, snap-to-grid, alignment guides, and color-coded layers. This setup accelerates adoption, reduces placement errors, and empowers designers to experiment with layouts without sacrificing accuracy.

Automation and batch processing are essential facets of the workflow. When evaluating DTF gangsheet builder features, look for auto nesting, automatic sheet generation from a design library, and bulk operations like applying a color profile across multiple designs. Compared with other solutions like DTF printing gang sheet software, top performers deliver reliable batch queuing, template-driven repeat jobs, and seamless asset flow from concept to print.

Color management and print accuracy for reliable DTF results

In the world of DTF garment printing software, color management is a core capability. A strong tool provides ICC profile support, soft proofing, and accurate previews that translate closely to the final print, helping you preserve brand color throughout the job stream.

Integration with printer profiles and RIP software keeps color data consistent across machines and fabrics. The ability to manage per-sheet or per-design color options and reliable color separation minimizes surprises at press, while proactive warnings about potential color conflicts save time and material costs.

Advanced nesting and layout optimization for high-throughput DTF workflows

Beyond simple placement, intelligent auto nesting analyzes design shapes and sizes to maximize transfer area while preserving margins and bleed requirements. Collision detection alerts you when designs would overlap in a way that would ruin a sheet, allowing adjustments before printing.

These capabilities shine when you work with diverse product lines or changing seasonal graphics. By optimizing layouts automatically, you reduce waste, speed up setup, and maintain consistency across dozens or hundreds of transfers per day, aligning with modern DTF workflow optimization tools.

Automation, batch processing, and file management in a DTF gangsheet builder

Automation and batch processing streamline repetitive tasks, translating time saved into higher throughput. Features like bulk color profile application, design variations for different sizes, and job queuing remove manual steps and lower the risk of human error.

Robust file management and flexible export options keep assets organized as catalogs grow. Look for clean library management for fonts, artwork, and templates, version control, and ready-to-print exports in formats like PNG, SVG, or PDF, all integral to scalable DTF production and the broader DTF gangsheet builder features.

Printer compatibility and ecosystem integration for seamless DTF production

A top-tier solution integrates smoothly with your printers, RIP software, and color management stack. Native support for bleed, margins, and alignment markers reduces guesswork and ensures daily reliability, while ecosystem integrations enable data to flow from design to print with minimal manual conversions.

Evaluating printer compatibility and vendor integrations helps prevent last-minute surprises. When the tool can push directly to your exact DTF printers and fit your existing software stack, it becomes a true command center for sheet planning, color, and job sequencing within a cohesive production workflow.

Collaboration, cloud options, and asset scalability in gangsheet design for DTF

On busy production floors, collaboration features and clear permission controls are essential. Cloud-based or local-network options with role-based access, change tracking, and secure project sharing enable real-time or asynchronous teamwork, boosting throughput and reducing miscommunication.

Font management and asset scalability ensure large catalogs stay performant. A strong gangsheet design tool for DTF supports a robust font library, licensing compliance, easy embedding of text, and scalable performance that handles thousands of designs with predictable export results. This aligns with broader needs in DTF garment printing software ecosystems and supports long-term growth.

Frequently Asked Questions

What is a DTF gangsheet builder and how do its features improve production?

A DTF gangsheet builder is a tool that plans, lays out, and prints multiple designs on transfer sheets, acting as a command center for sheet planning, color management, and job sequencing. Its features include a clear, grid-based UI with drag-and-drop placement, automation and batch processing to handle many designs, robust color management with ICC profiles and soft proofing, advanced nesting with collision detection, and seamless printer integration. By optimizing setup, reducing waste, and ensuring consistent placement across orders, it speeds production and improves accuracy in high-volume contexts. These DTF gangsheet builder features help teams scale catalogs, printers, and staff.

How does color management in a DTF printing gang sheet software ensure print accuracy?

Color management in a DTF printing gang sheet software centers on ICC profiles, soft proofing, and reliable color separations that translate to the actual print. Expect tight printer and RIP integration, per-sheet color options, and consistent previews that minimize surprises on press. When color data remains aligned across machines and materials, proofs match the final transfers, reducing rework and material waste.

What should I look for in DTF workflow optimization tools within a gangsheet design tool for DTF?

Key considerations include automation and batch processing, auto nesting that maximizes transfer space, templates for common sheet sizes, and bulk operations such as applying the same color profile to a batch. Look for file format compatibility (AI, PSD, SVG, PNG), easy queuing of multiple jobs, and flexible export options to printer-ready formats. Strong DTF workflow optimization tools should integrate smoothly with your existing design stack and production workflow.

How do advanced layout and nesting capabilities in a DTF gangsheet builder improve efficiency?

Advanced layout and nesting capabilities enable intelligent auto nesting, collision detection, reusable templates, and guides for margins and bleed. Auto nesting arranges designs to maximize transfer area while respecting spacing, and collision detection prevents overlaps before printing. These features save material, reduce setup time, and help designers adapt layouts quickly for new products.

Can a DTF garment printing software with a gangsheet builder integrate with my printers and RIP software?

Yes, look for native printer compatibility and seamless RIP integration in a DTF garment printing software. The tool should push job data directly to your DTG/RIP workflow, generate proper bleed and alignment markers, and support your fabric types. Smooth data flow minimizes conversions and rework and reduces downtime during peak periods.

What ROI and training resources should I expect from DTF gangsheet builder features?

When evaluating DTF gangsheet builder features, consider total cost of ownership (license, maintenance, hardware) and potential savings from reduced setup times and material waste. Estimate ROI based on time saved per job, increased production capacity, and improved order consistency. Look for onboarding materials, tutorials, and vendor-backed training resources to accelerate value realization.

| Feature | What it does | Why it matters | Keywords |

|---|---|---|---|

| Clear and intuitive user interface | Grid-based workspace with drag-and-drop placement, templates for standard sheet sizes, rulers, snap-to-grid, alignment guides, color-coded layers, onboarding tour | Speeds adoption, reduces errors, and accelerates layout work | UI, onboarding, templates, drag-and-drop, grid, guides |

| Automation and batch processing | Batch processing, automatic sheet generation from a design library, auto nesting, templates for common sheet sizes; bulk operations and multi-job queuing; supports AI/PSD/SVG/PNG | Increases throughput, ensures consistency, reduces manual steps; enables scalable production | batch processing, auto nesting, templates, bulk operations |

| Color management and print accuracy | ICC profiles, soft proofing, accurate previews, printer/RIP integration; per-sheet or per-design color options; color separation | Ensures color fidelity and reduces waste across machines and materials | ICC, color management, soft proofing, RIP |

| Advanced layout and nesting capabilities | Intelligent auto nesting, collision detection, reusable templates | Maximizes transfer area, avoids overlaps, supports frequent layout changes | nesting, collision detection, templates |

| File management and export options | Asset/library management, version control, export to PNG/SVG/PDF/print-ready formats; naming conventions and metadata; project tracking | Keeps catalogs organized and scalable; simplifies handoffs and audits | asset management, version control, export |

| Printer compatibility and ecosystem integration | Integrates with printers, RIPs, supports bleed/margins/markers; ecosystem interoperability | Reliable daily operation with minimal workarounds; data flows through design to print | printer integration, RIP, workflow |

| Font management and asset scalability | Robust font library, licensing compliance, easy embedding; scalable asset handling for thousands of designs | Maintains typography quality and supports large catalogs | font management, licensing |

| Collaboration, permissions, and cloud options | Cloud or local network options with role-based access, change tracking, secure sharing; real-time or asynchronous collaboration | Improves throughput and reduces miscommunications | collaboration, cloud, permissions |

| Reliability, performance, and updates | System requirements, platforms, regular updates/roadmap, vendor support | Reduces downtime; ensures long-term value and compatibility | reliability, performance, updates |

| Cost, ROI, and training resources | Total cost of ownership, ROI estimates, training resources | Balances price with value; faster time-to-value | cost, ROI, training |

Summary

DTF gangsheet builder is a powerful tool for planning and printing multiple designs on transfer sheets. The right solution aligns with your production realities, supports color and layout needs, and scales with your business, reducing setup time, material waste, and variation across orders. By prioritizing intuitive design, automation, color accuracy, advanced nesting, file management, printer integration, asset scalability, collaboration, reliability, and cost awareness, you position your operation for faster setup, reduced waste, and more consistent results. A well-chosen DTF gangsheet builder helps designers work confidently and operators run more jobs per shift with fewer errors.