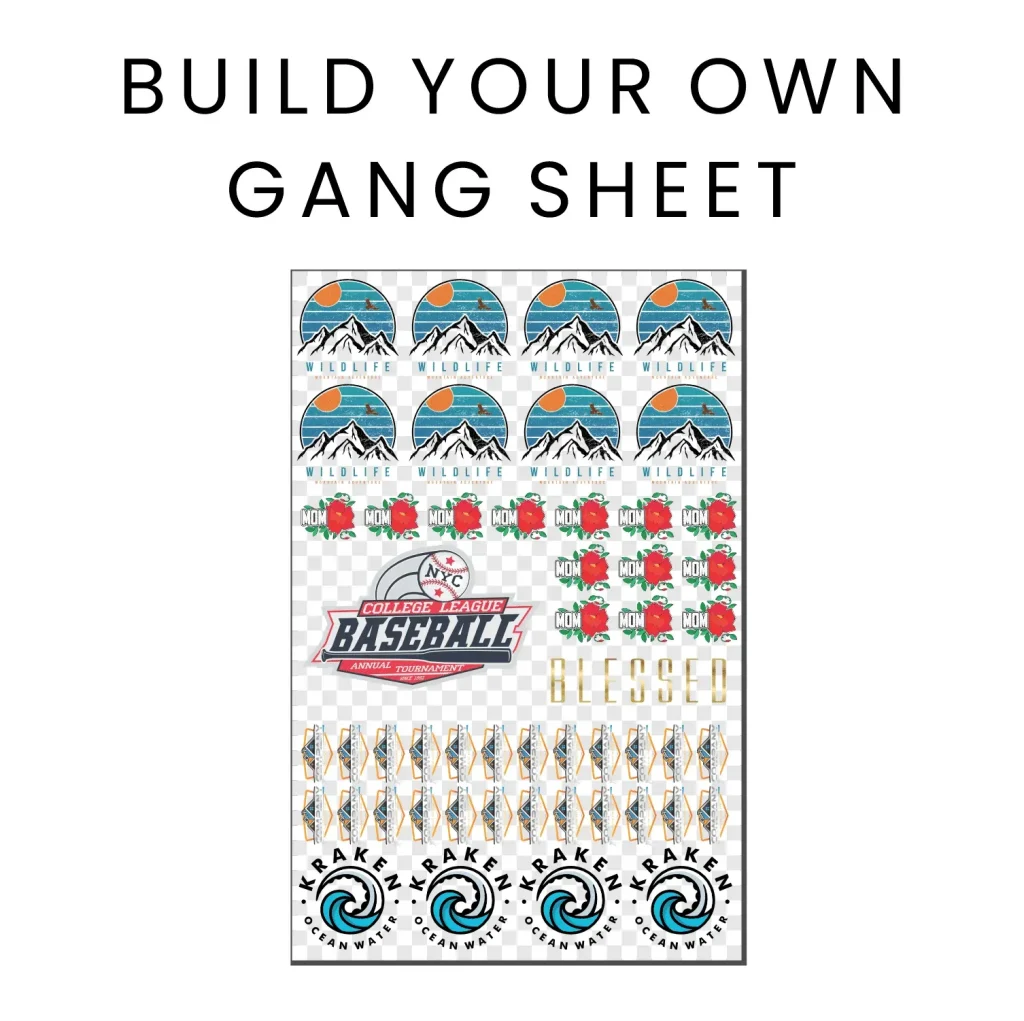

The DTF Gangsheet Builder is a game-changer in the world of Direct-to-Film printing, offering an innovative way to streamline the garment decoration process. With its ability to print multiple designs on a single sheet, this tool significantly optimizes material use and improves efficiency for businesses, allowing for stunning, vibrant prints on various fabrics. If you’re looking to master the art of DTF printing, familiarizing yourself with essential techniques and tips is crucial. This guide delves into the intricacies of DTF printing, including advice on gangsheet printing strategies, effective use of transfer films, and perfecting heat press settings. Unleashing the full potential of your DTF Gangsheet Builder can elevate your printing quality and provide a competitive edge in the industry.

Direct-to-Film (DTF) printing has rapidly become a favored method for garment decoration, particularly when utilizing innovative gangsheet builders. This technique not only enhances the efficiency of printing but also ensures high-quality results by allowing users to combine various designs onto a single transfer sheet. Understanding the fundamental aspects of DTF printing, coupled with effective techniques and careful selections of transfer materials, is essential for achieving professional outcomes. Moreover, optimizing printer settings and heat press operations plays a significant role in the quality of the final product. Whether you’re a seasoned professional or just venturing into the realm of DTF, mastering these aspects will certainly boost your print outputs.

Essential DTF Printing Tips for Beginners

When venturing into the world of Direct-to-Film (DTF) printing, beginners should prioritize understanding the basic principles that contribute to exceptional results. One vital aspect is ensuring that your artwork is generated at a high resolution, ideally 300 DPI, which will enhance clarity and detail in your prints. Additionally, it’s crucial to use the CMYK color mode throughout your design process, as this will ensure the colors printed reflect the digital artwork accurately, leading to less disappointment in the final outcome.

Moreover, utilizing vector graphics can significantly improve your printing flexibility. Unlike raster images that lose quality when resized, vector graphics maintain their integrity regardless of scaling. This means that you can create designs that fit perfectly within your DTF gangsheet without worrying about pixelation, allowing for professional-grade prints every time.

Maximizing Efficiency with DTF Gangsheet Builder

DTF gangsheet builders revolutionize the way designs are printed by maximizing the use of available space on transfer films. This method allows multiple designs to be printed simultaneously, which not only saves on material costs but also reduces the time needed for production. To achieve maximum efficiency, ensuring optimal layout arrangements is crucial; proper orientation and strategic placement of your designs can help minimize wasted film area.

By optimizing the gangsheet layout using graphic design programs, you can streamline your production process significantly. Tools such as Adobe Illustrator provide functionalities to assess and adjust the spacing and placement of each design, ensuring that as much area as possible is utilized. This focus on efficiency through a well-structured gangsheet can lead to greater output in less time while keeping production costs low.

Choosing the Right Transfer Films for DTF Printing

Selecting the right transfer film is critical in achieving high-quality DTF prints. High-quality films ensure better adhesion and durability, essential for long-lasting designs on garments. PET (Polyethylene Terephthalate) film is often recommended due to its exceptional heat resistance and capability to withstand the high temperatures during the heat transfer process. Utilizing quality transfer films not only boosts print vibrancy but also enhances the overall adhesive performance on various fabrics.

Furthermore, consider how the chosen film interacts with DTF specific inks. Not all films are created equal, and using films unsuitable for DTF applications may result in poor print quality and low adhesion. Always check the manufacturer’s specifications to ensure compatibility with the inks being used, as this will directly impact the final print outcome.

Mastering DTF Printer Settings for Optimal Results

Getting familiar with your DTF printer’s settings is indispensable for achieving optimal print results. Variations in fabric type necessitate different adjustments—parameters such as temperature, speed, and pressure all play significant roles in the final output. For instance, cotton t-shirts typically require a different heat setting than polyester blends, so it’s essential to consult your printer’s documentation for specific guidelines that correspond to your material choices.

Additionally, fine-tuning these settings based on the feedback from test prints can help in finding the sweet spot for each type of fabric. Regular calibration and testing will allow you to adapt to different projects and clients’ needs more effectively, marking a significant step towards mastering DTF printing.

Heat Press Techniques for Successful Transfers

Successful DTF printing heavily relies on mastering the heat press technique, which can ultimately make or break your project. One critical aspect involves setting the correct temperature and pressure—most DTF applications suggest a temperature of around 320°F (160°C) for 10-15 seconds. However, these factors can vary depending on the fabric type, requiring adjustments for optimal results.

Moreover, it’s essential to maintain even pressure during the application process. Uneven pressure might lead to areas that are poorly adhered, resulting in peeling or flaking designs. Familiarity with your heat press machine and consistent practice will refine your approach, ensuring that you achieve lasting and vibrant results on fabric.

Care Instructions Post-Transfer for Longevity

After successfully transferring designs onto garments, providing proper care instructions becomes paramount to extending the life of the prints. Advising clients to wash the items in cold water and to avoid harsh detergents can greatly enhance the durability of the prints. Additionally, recommending air drying over tumble drying can help preserve both the fabric and the printed design, minimizing the risk of heat damage that can cause prints to fade or peel.

Communicating these care instructions effectively ensures that end-users appreciate the quality of your DTF prints and trust in your expertise. A well-informed client is more likely to return for future business, reinforcing the importance of not only the printing process but also the longevity of the finished product.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a tool designed for Direct-to-Film (DTF) printing that allows users to print multiple designs on a single film sheet. This method enhances efficiency by maximizing the use of printing materials and reducing waste. It works by assembling various designs closely on the gangsheet, which is then printed using specialized DTF printers.

What are some essential DTF printing tips for using a gangsheet builder?

Some essential DTF printing tips include ensuring your designs are in high resolution (300 DPI) and in CMYK color mode, optimizing your print layout to minimize gaps, and using high-quality transfer films and DTF-specific inks. Additionally, mastering heat press settings and understanding adhesive application are crucial for achieving successful prints.

How do heat press settings affect DTF gangsheet printing?

Heat press settings are critical to the success of DTF gangsheet printing. For optimal adhesion, you should typically set your heat press to around 320°F (160°C) for 10-15 seconds. However, nuances depending on the fabric type may require adjustments in temperature, pressure, or time to ensure perfect transfers without damaging the material.

What type of transfer films should I use for DTF gangsheet printing?

For DTF gangsheet printing, using high-quality transfer films is vital. It’s recommended to use Polyethylene Terephthalate (PET) films, as they are specifically tailored for DTF applications, offering excellent heat resistance and adhesion properties. Choosing the right film can significantly enhance print durability and quality.

What are the key DTF printing techniques for successful gangsheet transfers?

Key DTF printing techniques include ensuring designs are vector files for scalability, applying a consistent layer of adhesive powder for proper adhesion, and allowing prints to cool completely before peeling the film. Additionally, utilizing specialized inks formulated for DTF printing will maximize vibrancy and enhance washing durability.

What recent trends are emerging in DTF gangsheet printing technology?

Recent trends in DTF gangsheet printing technology include the adoption of automated DTF gangsheet builders, which streamline the printing process and enhance efficiency. These tools often integrate seamlessly with design software, allowing for a more cohesive workflow and enabling professionals to keep pace with evolving market demands.

| Key Point | Description |

|---|---|

| Introduction | DTF printing is a revolutionary method for garment decoration, optimizing material use. |

| Design Compatibility | Ensure designs are 300 DPI, in CMYK mode, and preferably in vector format. |

| Optimizing Print Area | Use software to minimize gaps and maximize the use of the film surface. |

| Choosing the Right Film | Select high-quality, DTF-specific PET films for better adherence and results. |

| Ink and Powder Adhesives | Use DTF-specific inks and ensure a consistent application of adhesive powder. |

| Printer Settings | Adjust settings based on fabric type for optimal printing. |

| Mastering Heat Press Technique | Set heat press to 320°F for 10-15 seconds for optimal adhesion. |

| Post-Transfer Care | Allow prints to cool completely and provide care instructions to users. |

| Recent Trends | Adoption of automated DTF gangsheet builders is increasing, enhancing efficiency. |

Summary

DTF Gangsheet Builder is an essential tool in the realm of garment decoration, allowing users to optimize their printing process and produce high-quality designs with ease. By understanding the fundamentals of DTF printing, from ensuring design compatibility to mastering printer settings and heat transfer techniques, you can significantly improve the quality and efficiency of your prints. It’s vital to stay updated on recent trends, such as automated DTF gangsheet builders, which further streamline the workflow. Incorporating these techniques and insights will not only enhance your printing capabilities but also keep your business competitive in the ever-evolving market.