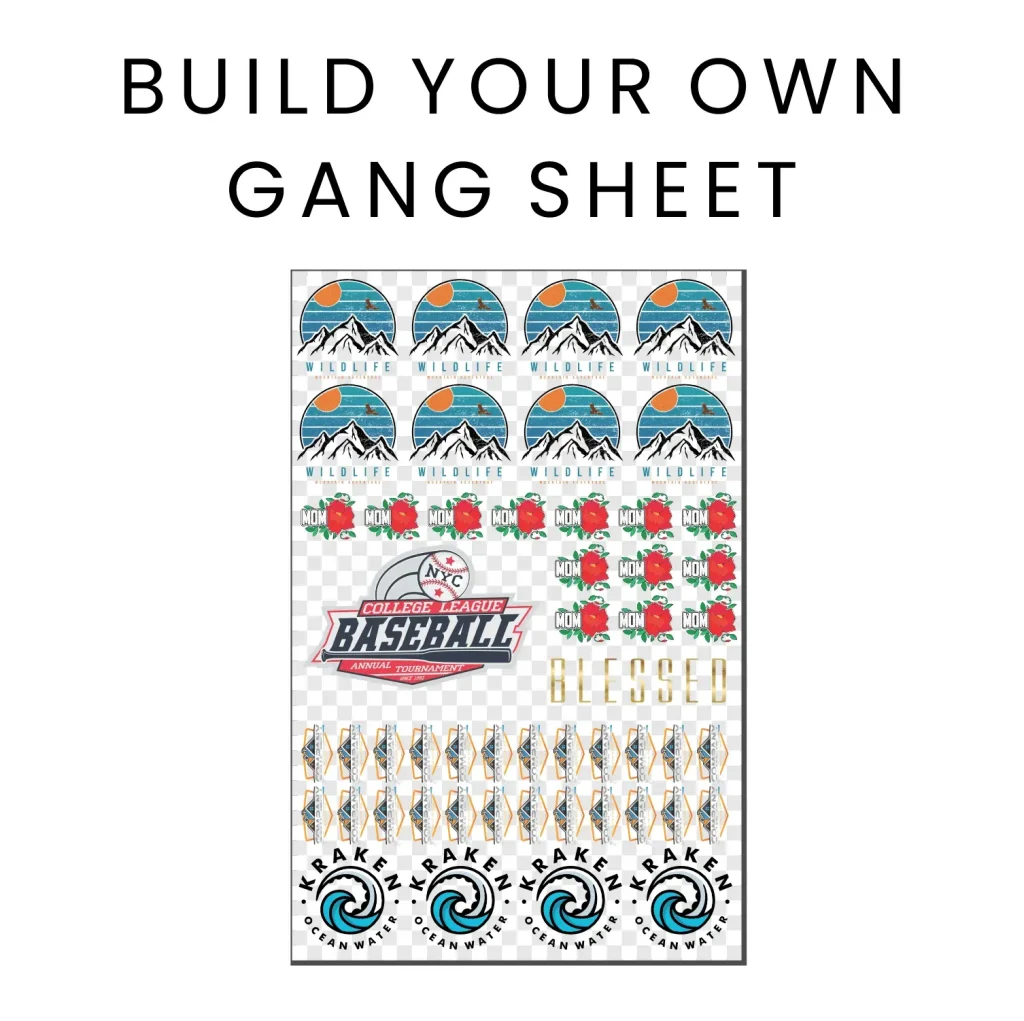

In the realm of custom apparel printing, the **DTF gangsheet builder** stands out as a transformative tool that enhances both efficiency and creativity. As Direct to Film (DTF) printing continues to redefine the landscape of garment decoration, mastering the gangsheet builder becomes essential for maximizing production capabilities. This innovative software enables users to optimize layouts, ensuring that multiple designs are printed simultaneously on a single sheet, saving time and reducing material wastage. By leveraging the advantages of DTF printing alongside the strategic capabilities of a gangsheet builder, businesses can elevate their operational efficiency while delivering vibrant, high-quality designs for their customers. Whether you’re a seasoned printer or a newcomers in DTF, understanding the functionalities of the gangsheet builder will significantly streamline your printing processes.

The process of creating custom designs for garments has evolved with the introduction of modern printing solutions like the DTF gangsheet creator. This term refers to a specialized tool designed to enhance direct film printing, efficiently arranging multiple graphics on a single sheet, often known as gang sheets. By facilitating a seamless printing workflow, this technology not only minimizes waste but also maximizes the potential of every print run. Entrepreneurs focused on custom textile decoration can experience significant gains in both productivity and creativity through the effective use of gangsheet builders. As the demand for personalized apparel grows, adopting these advanced tools becomes imperative for staying competitive in the custom printing market.

Maximizing Efficiency with DTF Printing Techniques

In the realm of custom apparel printing, maximizing efficiency is essential for sustainable growth and profitability. DTF printing technology stands out in this regard by its ability to produce vibrant, durable prints quickly and with minimal waste. Understanding the full potential of DTF means knowing how to optimize print settings, align designs strategically, and manage the printing workflow efficiently. By harnessing techniques such as utilizing optimal print resolutions and maximizing ink usage, businesses can significantly reduce operational costs and improve turnaround times.

Moreover, implementing effective workflow strategies, such as scheduling print jobs during off-peak hours or batching similar designs, can enhance output rates while maintaining high-quality standards. An efficient operation not only satisfies customer demands for quick deliveries but also creates a seamless experience in the overall production process. As the DTF printing landscape continues to evolve, staying on top of industry trends and adopting innovative practices will be critical for achieving sustained operational excellence.

Understanding the Benefits of Gang Sheets in DTF Printing

Gang sheets play a transformative role in maximizing the benefits of DTF printing by enabling several designs to be printed simultaneously on a single sheet. This strategic approach to layout not only conserves material but also optimizes the overall printing process, making it a favorite among custom apparel manufacturers. When utilizing gang sheets, businesses can meet deadlines more efficiently while decreasing production costs associated with individual print runs. This is particularly beneficial for startups and small businesses aiming to balance quality with affordability.

Incorporating gang sheets into your workflow further enhances flexibility in design choices, allowing for varied and intricate patterns to be applied concurrently. This efficiency lends itself to the production of unique custom products that cater to diverse customer preferences. By understanding and leveraging the advantages of gang sheets within the framework of DTF printing, entrepreneurs can create a competitive edge in a saturated market, responding to customer needs without compromising on quality or turnaround time.

Effective Design Arrangement on DTF Gang Sheet Builders

One of the crucial aspects of using a DTF gangsheet builder effectively is the arrangement of designs. Proper design placement on the gang sheet can significantly affect the quality and efficiency of the printing process. Ensuring adequate spacing between each design is vital to avoid overlap, which can lead to printing errors and wasted materials. Additionally, strategically grouping designs of similar sizes and shapes helps optimize the sheet’s space, allowing the printer to maximize the output from each run.

Furthermore, understanding how to utilize the dimensions of the gang sheet to your advantage is essential for creating profitable designs. Experimenting with different layouts and utilizing software that offers flexibility in design adjustments can greatly enhance the overall output quality. As application methods improve, employing smart arrangements can also lead to better post-printing processes, such as heat transfers, where mistakes are minimized, thus boosting overall production reliability.

Color Management Strategies for DTF Printing

Effective color management is a cornerstone of successful DTF printing, ensuring that the colors seen on the design mockups translate accurately to the final product. By incorporating specific color profiles tailored for DTF printing into the workflow, creators can achieve greater consistency and vibrancy in their printed designs. It is essential for printers to regularly calibrate their equipment and perform test prints, allowing adjustments to be made before committing to larger production runs.

In addition to color calibration, utilizing software that supports advanced color management features can significantly improve results. Adjusting color settings according to the specific fabrics being used can help achieve deeper blacks, brighter tones, and a wider color gamut. By mastering these color management techniques alongside the unique capabilities of DTF printing, businesses can elevate their product quality, resulting in customer satisfaction and repeat business.

Leveraging Technology in DTF Printing

The advancements in printing technology are pivotal in enhancing the quality and efficiency of DTF printing. Modern printers come equipped with high-speed capabilities and enhanced ink formulations that contribute to a more streamlined production process. The development of eco-friendly inks is also reshaping the industry, appealing to a modern consumer base that values sustainability without compromising quality. Integrating these advanced technologies into daily operations allows businesses to not only keep up with demand but also to set higher standards for performance.

Moreover, utilizing the latest software innovations provides new opportunities for designers and printers alike. Tools that offer features such as automated color adjustments, template layouts, and production planning can reduce the likelihood of human error and improve overall efficiency. To stay competitive, print businesses should invest in emerging technologies and continuously explore ways to implement these advancements into their workflow strategies.

Community Engagement in DTF Printing Practices

Engaging with community resources can be incredibly beneficial for entrepreneurs in the DTF printing space. Online forums, social media groups, and industry associations host invaluable discussions where users share techniques, challenges, and success stories. Actively participating in these communities allows printers to learn from peers, explore innovative design strategies, and stay informed about the latest trends and technologies shaping the DTF printing landscape.

Additionally, networking within these platforms can offer collaboration opportunities that might not have been considered otherwise. Sharing knowledge, troubleshooting common issues, and even sourcing materials from trusted community recommendations can contribute to a more robust and informed printing process. By tapping into these resources, entrepreneurs not only foster a supportive environment but also create a network of contacts that can lead to business growth and shared success.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work in DTF printing?

A DTF gangsheet builder is a software tool designed to optimize the layout of multiple designs on a single transfer sheet used in Direct to Film (DTF) printing. It reduces material waste and costs by efficiently arranging individual designs, ensuring proper spacing for clean transfers. This helps improve overall printing efficiency and speeds up the production process.

How can using a DTF gangsheet builder improve custom apparel printing?

Using a DTF gangsheet builder enhances custom apparel printing by maximizing the use of printing materials and reducing waste. It allows for arranging various designs on one sheet, which not only saves costs but also streamlines the transfer process. This leads to more efficient production runs, ideal for small business owners in the custom printing market.

What are the benefits of utilizing gang sheets in DTF printing?

Gang sheets in DTF printing provide several benefits including cost savings through optimized material usage, reduced production time, and improved design alignment during transfers. They allow for multiple designs to be printed simultaneously, making them a practical solution for custom apparel creators looking to enhance their efficiency.

What should I consider when arranging designs on a DTF gangsheet?

When arranging designs on a DTF gangsheet, consider spacing between designs to allow for clean cuts and transfers. Additionally, group designs of similar sizes to make the most of the material. Shape considerations are also important to optimize layout and minimize waste, ultimately improving printing efficiency.

How does color management impact the quality of prints from a DTF gangsheet builder?

Color management is crucial in DTF printing as colors can vary depending on the fabric used. Utilizing specific color profiles tailored for DTF printing helps achieve better color accuracy and vibrancy. Test prints should be conducted to ensure colors translate well from screen to fabric, allowing adjustments to be made for optimal results.

What trends are emerging in DTF printing technology that can affect gangsheet builders?

Emerging trends in DTF printing technology include advancements in printer capabilities, improved ink formulations, and new software innovations that enhance printing speeds and quality. Eco-friendly inks are gaining traction, catering to environmentally conscious consumers. Keeping up with these trends will ensure that users of DTF gangsheet builders stay competitive and efficient in their printing processes.

| Key Point | Explanation |

|---|---|

| Understanding DTF Printing | A modern printing method that transfers designs onto fabrics using heat and adhesive. |

| What is a Gangsheet? | A strategic layout that allows multiple designs to be printed on a single sheet, optimizing material use. |

| Effective Utilization of DTF Gangsheet Builder | Maximizing efficiency through design arrangement, color management, and software proficiency. |

| Recent Technological Developments | Advancements in printer technology and eco-friendly inks improve quality and sustainability. |

| Community Insights and Resources | Online communities provide support, sharing methods and troubleshooting strategies. |

| Future Trends | Growing demand for custom apparel drives innovation and improvements in DTF printing processes. |

Summary

DTF gangsheet builder is a crucial tool in enhancing your custom printing efficiency. This guide emphasizes the significance of understanding DTF printing, utilizing gang sheets properly, and keeping abreast of technological advancements. It’s important for creators to optimize their design arrangements and color management while leveraging community resources. As the market for custom apparel expands, mastering the use of a DTF gangsheet builder will allow businesses to thrive, streamline production, and ultimately transform creative ideas into successful products.