DTF printing techniques have become a game-changer in the custom apparel and textile printing industry with their ability to deliver vibrant colors and intricate designs. This innovative approach, known as Direct to Film printing, allows artists and businesses to print high-quality graphics directly onto transfer films before applying them to garments. Unlike traditional screen printing, DTF offers superb flexibility and the potential for endless creativity, making it a favorite among modern decorators. To fully tap into this revolutionary printing method, understanding the nuances of DTF printing is essential. In this article, we’ll dive into top tips that will elevate your DTF printing skills to new heights, ensuring stunning, durable results each time.

Exploring custom fabric printing methods, one might encounter techniques like Direct to Film that elevate the visual impact of printed apparel. Utilizing innovative processes in textile printing, this technique stands out for its exceptional adaptability and vivid prints. Compared to conventional methods such as screen printing, the benefits of DTF printing become increasingly clear as it provides a smoother transition from design to finished product. For those keen on enhancing their skills in this craft, focusing on critical aspects such as material quality and application techniques will greatly improve the overall outcomes. As we uncover the essentials of DTF printing tips, you’ll be equipped to create eye-catching wearables that truly resonate with your audience.

Understanding DTF Printing Techniques

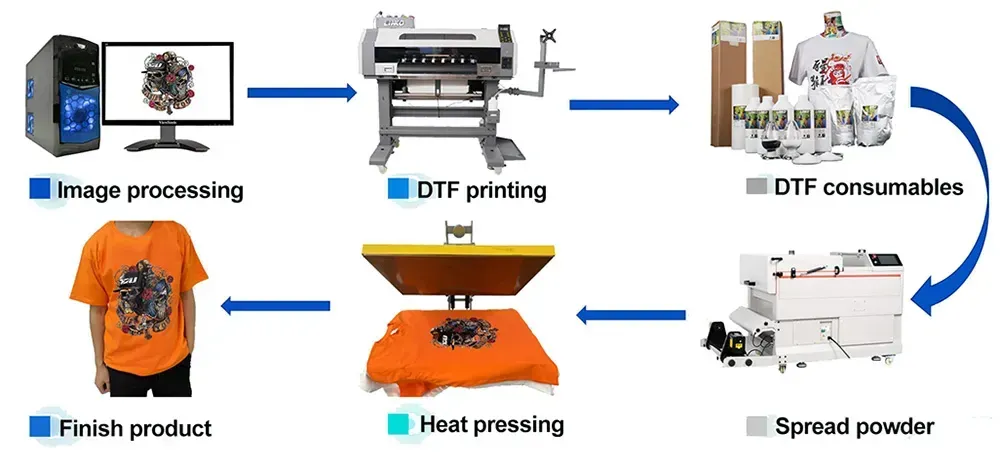

Direct to Film (DTF) printing is a modern textile printing technique that has transformed the custom apparel industry. Unlike traditional screen printing, which requires separate screens for each color, DTF printing utilizes a single film transfer that can capture intricate designs and multiple colors. This method not only streamlines the printing process but also reduces production time, making it a favored choice for businesses looking to meet tight deadlines. Understanding the nuances of DTF printing techniques allows artists and entrepreneurs alike to unlock their creative potential and produce high-quality prints quickly and efficiently.

Additionally, DTF printing techniques allow for a range of applications beyond just apparel, including accessories and home textiles. The versatility of DTF transfers can cater to various fabric types, such as cotton, polyester, or blends, making it a valuable addition to any printing repertoire. By mastering these techniques, you can expand your product offerings and appeal to a broader customer base. Whether you’re creating custom t-shirts for a music festival or unique designs for corporate branding, DTF printing can meet diverse demands with remarkable clarity and color vibrancy.

Essential Tips for Quality Control in DTF Printing

Quality control is paramount in achieving optimal results in DTF printing. One of the key aspects of maintaining quality is conducting thorough tests before the final run. Print sample designs on different fabrics and settings to ensure you achieve the desired output. This step will not only help in fine-tuning printer settings but will also offer insights into how different inks and transfer films behave with each other. Moreover, creating a checklist for each printing session can help keep track of critical settings and the quality of materials to ensure consistency in every batch produced.

Furthermore, using high-definition images as a starting point is crucial for quality assurance. Ensure that the artwork intended for DTF printing is of high resolution and that any color profiles are appropriately set for the printer. Low-quality images can result in pixelation and loss of detail, leading to underwhelming results. By prioritizing quality control at each stage of the printing process, from design to final application, you will set yourself up for success in delivering vibrant and durable prints that meet the expectations of your clients.

The Importance of Choosing the Right Transfer Film

The choice of transfer film significantly impacts the overall quality of DTF prints. High-quality DTF transfer films are designed to effectively adhere to fabric while maintaining brilliant colors and sharp images. When choosing transfer films, consider factors such as thickness, adhesiveness, and compatibility with the inks being used. Some films are better suited for cotton fabrics, while others perform exceptionally on polyester or blended materials. Investing in the right transfer film gives your prints longevity and vibrancy, which are key components in the competitive fabric printing market.

Moreover, the application of transfer films must be executed accurately for best results. Using the appropriate temperature and pressure settings ensures that the ink adheres properly to the substrate, preventing issues like peeling or cracking over time. Performing tests with different films can help identify which ones work best with your machinery and settings, ultimately allowing for a refined printing process. By understanding and selecting the right transfer film, you can improve the durability and aesthetic appeal of your custom apparel.

Mastering Application Techniques in DTF Printing

Mastering the application techniques in DTF printing is crucial for achieving high-quality results. The process involves pressing the transfer film onto the garment with precision to ensure a durable bond between the print and the fabric. The ideal setup typically includes a heat press machine that allows for adjustable temperature and pressure settings. Understanding the optimal combinations based on the type of fabric and the specific transfer film being used can make all the difference in the final output. Typical temperatures for DTF application should be maintained between 300°F to 330°F, along with correct pressure for best adhesion.

Practice makes perfect, and applying DTF prints can require a bit of fine-tuning. Conducting multiple test prints helps in determining the most effective heat and time settings. Each garment type might react differently to heat and pressure, so documenting the settings that yield the best results is advisable. By perfecting the application techniques, not only will you enhance print durability, but you will also ensure that your artwork retains its vibrant colors and fine details, ultimately leading to higher customer satisfaction.

Post-Printing Care Tips for DTF Prints

The care taken after printing is just as important as the printing process itself. To prolong the vibrancy and longevity of DTF prints, specific care instructions should be followed. Washing garments inside-out in cold water is a simple yet effective way to prevent fading while also protecting the print from abrasion during laundry cycles. Avoidance of harsh chemicals such as bleach is essential, as they can erode the ink and compromise the quality of the garment.

Moreover, allowing the prints to cure fully before wearing or washing them is crucial to ensure maximum adhesion. This post-printing care routine can significantly extend the life of your designs, making them look fresh and new for an extended period. Offering care tips to your customers not only enhances their experience but also establishes your credibility as a professional in the custom apparel printing industry, ensuring repeat business and customer loyalty.

Keeping Up with Trends in DTF Printing Techniques

The landscape of DTF printing is constantly evolving, with new trends and technologies emerging. Keeping up with these changes is essential for anyone in the custom apparel industry looking to enhance their skills and services. Subscribing to industry newsletters or joining online forums can provide valuable insights into the latest printing techniques and materials. Attending workshops and trade shows not only expands your knowledge but also offers networking opportunities with other professionals and manufacturers who can provide the latest updates on printing innovations.

Additionally, being aware of consumer preferences and market trends can help you adapt your practices accordingly. For instance, the growing demand for sustainable printing methods is reshaping the industry, prompting many to seek eco-friendly inks and recyclable films. By integrating these sustainable practices into your DTF printing process, you not only meet market demands but also establish your brand as a responsible leader in the apparel printing sector. Staying informed about these trends not only enhances both personal skills and business viability but positions you strategically in an increasingly competitive market.

Frequently Asked Questions

What are the key benefits of using DTF printing techniques for custom apparel?

DTF printing techniques offer several benefits for custom apparel, including vibrant colors, superior detail, and versatility across various fabrics. Unlike traditional screen printing, DTF allows for complex designs and gradients, making it ideal for small runs and customized designs. Additionally, DTF prints are highly durable and can withstand multiple washes without fading, ensuring long-lasting quality.

How can I improve my DTF printing results using the right materials?

To enhance your DTF printing results, always invest in high-quality DTF transfer films and inks that are compatible with your equipment. Choosing films with a smooth surface finish ensures better heat transfer adhesion. Moreover, using professional-grade inks will contribute to vibrant and long-lasting prints, which is essential for custom apparel printing.

What printer settings should I adjust for optimal DTF printing results?

For optimal DTF printing results, you should adjust your printer’s resolution, select the appropriate color profile, and ensure the right ink application settings are utilized. Performing test prints will help you fine-tune these settings based on the specific DTF transfer film and ink you are using, ultimately leading to higher quality outputs.

What are the best application techniques for transferring DTF prints onto garments?

The best application techniques for transferring DTF prints involve proper calibration of your heat press. Standard temperatures range from 300°F to 330°F with pressing times between 15 to 20 seconds. Testing various combinations of heat and pressure will help you achieve optimal adhesion and avoid damaging the garment or the print, which is crucial for high-quality custom apparel printing.

How should I care for DTF printed garments to maintain their quality?

To maintain the quality of DTF printed garments, wash them inside out in cold water, and avoid bleach or harsh detergents that can damage the print. Additionally, ensure the prints are fully cured before washing or wearing the items. These care practices will help preserve the vibrancy and durability of your DTF prints over time.

What resources are available for learning more about DTF printing techniques?

There are plenty of resources available for learning more about DTF printing techniques, including industry blogs, forums, and workshops. Engaging with the printing community through events or online platforms will help you stay updated on the latest trends and innovations in DTF, allowing you to enhance your skills and improve your printing results.

| Tip | Key Points |

|---|---|

| Invest in Quality Materials | Use high-quality DTF transfer films and inks for vibrant, long-lasting prints. |

| Get Your Printer Settings Right | Adjust printer resolution, color profiles, and ink application for optimal results. |

| Perfect Application Techniques | Calibrate heat press correctly; use specific temperatures and times for better adhesion. |

| Post-Printing Care | Wash garments carefully and allow prints to cure for longevity. |

| Stay Updated on Techniques and Trends | Engage with the printing community to learn about new tools and materials. |

Summary

DTF printing techniques are essential for achieving high-quality results in custom apparel and textile printing. This innovative method not only offers vibrant colors and versatility but also requires an understanding of various elements to master the technique fully. By investing in quality materials, adjusting printer settings appropriately, applying transfers with precision, and caring for your print garments, you can significantly enhance your DTF printing skills. Staying updated with the latest trends and techniques will further elevate your expertise, ensuring your prints stand out in the competitive market. Ultimately, mastering DTF printing techniques leads to stunning, durable prints that meet the needs of both hobbyists and professionals.