DTF transfers, short for Direct-to-Film transfers, have revolutionized the world of custom apparel by offering unmatched quality and versatility in printing. This innovative technique allows for intricate designs with vibrant colors that not only stand out but also endure over time, making them a preferred choice for many clothing brands. As we delve into DTF transfers, we will explore essential DTF printing advantages and provide insightful DTF transfer tips to help you master the process. Whether you’re a seasoned professional or just starting out, understanding how to DTF transfers can elevate your design game significantly. Join us on a journey to unlock the magic behind custom apparel DTF and discover the secrets to achieving stunning prints that leave a lasting impression.

Direct-to-Film printing, often abbreviated as DTF, represents a cutting-edge approach to fabric decoration that is capturing the attention of designers and crafters alike. This process involves transferring detailed imagery onto garments through a specialized film, making it an excellent option for those looking to create unique and personalized apparel. With its growing popularity, many are discovering the various techniques and benefits associated with this innovative printing method, from easy application to its unparalleled color richness. Understanding the fundamentals of applying DTF transfers can significantly enhance your craft, whether you’re producing one-off custom items or large quantities of merchandise. As we explore this dynamic printing technique, you’ll learn how to master DTF printing while gaining insights into its numerous advantages for the fashion market.

Unlocking the Benefits of DTF Transfers

DTF transfers offer a plethora of advantages for those involved in custom apparel creation. Unlike traditional methods that often limit color options, Direct-to-Film (DTF) printing allows for full-color designs that are rich, vibrant, and capable of capturing the finest details. This means that you can create striking visuals that are sure to stand out in a competitive market, appealing to customers who value quality and aesthetics.

In addition to their vibrant color output, the durability of DTF transfers is another significant benefit. With high-quality inks and strong adhesive properties, designs created with DTF printing process won’t easily fade or peel, even after multiple washes. This reliability makes DTF a preferred choice for businesses looking to enhance customer satisfaction while ensuring their garments remain in great condition over the long term.

Essential Tools for Successful DTF Printing

Understanding which tools are necessary for successful DTF printing is crucial for any aspiring printer. A high-quality DTF printer and specialized DTF inks are fundamental to achieving vibrant and consistent results. The importance of investing in the right equipment cannot be overstated, as this directly affects the clarity and fidelity of your prints.

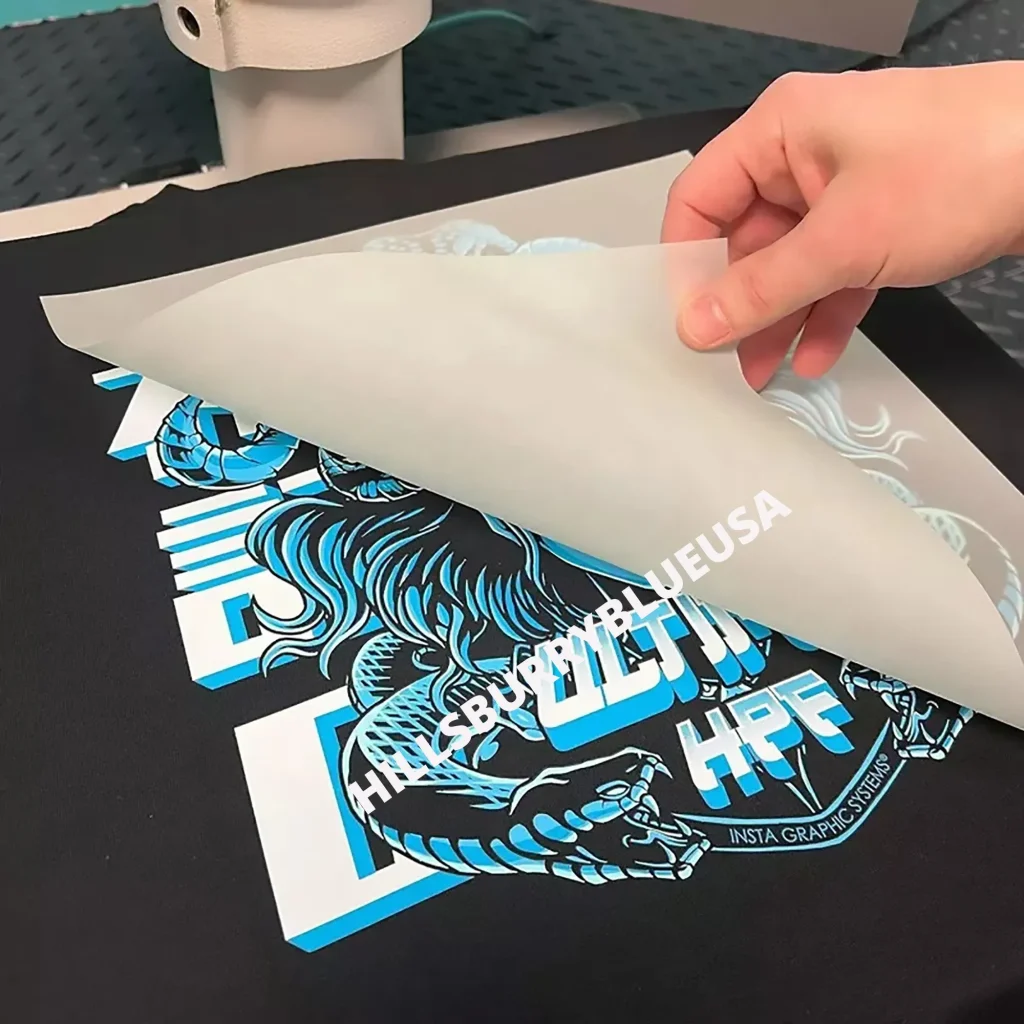

Additionally, a reliable heat press machine is vital for applying the DTF transfer effectively. It not only ensures even heat distribution but also allows for the correct pressure to be applied during the transfer process. Moreover, having high-quality powder adhesive is essential to create lasting bonds between the film and fabric, which is crucial for the longevity of the prints.

Tips for Perfecting Your DTF Transfer Technique

Achieving stunning DTF prints requires attention to various technique details. One of the first steps is to adjust your printing settings, especially ink density and feed rate. By experimenting with these parameters, printers can find the optimal balance that brings designs to life with the correct vibrancy.

Another important aspect is the application of the powder adhesive. Striking the right balance of coverage is key; using too much can lead to an undesirable texture, while too little can cause the designs to peel off. Utilizing a shaker for even distribution and conducting tests on scrap fabric can help in mastering this essential step.

Post-Transfer Care for Longevity

Once your DTF transfer is applied, proper care is essential to maintain its quality. Advising customers to wash garments inside out in cold water not only preserves the print but also prevents wear. This simple step can significantly extend the lifespan of DTF designs, allowing customers to enjoy their custom apparel for years.

Moreover, informing customers about avoiding harsh chemicals during washing is critical. Products like bleach can drastically affect the visual quality of DTF prints over time. By educating consumers on how to care for their apparel, you can ensure a higher level of satisfaction and repeat business.

Market Trends Influencing DTF Printing

As the trend for personalized apparel continues to grow, the market for DTF printing is also expanding. Many businesses are taking advantage of the cost-effectiveness this method offers, which can lead to higher profit margins and greater customer appeal. The versatility of DTF technology allows businesses to cater to both small and large order quantities efficiently.

Additionally, consumer preferences are shifting towards unique, customized garments that are not only stylish but also durable. This burgeoning demand is driving more designers and brands to experiment with DTF techniques, highlighting the need for printers to keep up with market innovations and trends.

Future Outlook of DTF Transfers in Custom Apparel

Looking ahead, the future of DTF transfers appears promising as more brands seek to incorporate personalization into their product offerings. As digital printing technology continues to evolve, DTF printing is likely to become increasingly efficient and accessible, making it an attractive choice for both startups and established businesses.

Furthermore, innovations in ink formulations and transfer films are expected to enhance the quality and functionality of DTF prints. As manufacturers continue to develop better materials and processes, the potential for DTF transfers in custom apparel seems boundless, encouraging creativity and exciting designs in the fashion market.

Frequently Asked Questions

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages for custom apparel, including vibrant colors that do not fade over time, excellent durability for frequent wear and washing, and the flexibility to handle both small orders and large production runs. This makes DTF printing an appealing choice for designers looking to create unique and long-lasting apparel.

How do I properly apply DTF transfers to fabrics?

To successfully apply DTF transfers, start by adjusting your heat press to about 320°F (160°C). Ensure the fabric is clean and flat, then place the DTF transfer on the desired spot. Apply moderate pressure for around 15 seconds. Always perform a test application to optimize settings for different fabric types.

What materials do I need for effective DTF printing?

For effective DTF printing, you will need a high-quality DTF printer, specialized DTF inks, powder adhesive for bonding the transfer, and a reliable heat press machine. Investing in these materials is crucial for achieving bright and durable prints on your custom apparel.

Can DTF transfers be used on any fabric type?

Yes, one of the key benefits of DTF transfers is their versatility; they can be used on a variety of fabrics, including cotton, polyester, and blends. This makes DTF a suitable choice for diverse custom apparel projects.

What are some DTF transfer tips for beginners?

Beginners should focus on adjusting printer settings for ink density, ensuring even powder adhesive application, and mastering heat press techniques. It’s also recommended to read care instructions for post-transfer maintenance to prolong the print’s lifespan.

Is DTF printing cost-effective for small orders?

Absolutely! DTF printing is particularly cost-effective for small orders due to its flexibility; it allows for detailed and colorful designs without the setup costs associated with traditional printing methods. This makes it a great option for personal projects or small business ventures.

| Key Point | Details |

|---|---|

| Definition | Direct-to-Film (DTF) transfers involve printing designs on a special film, which are then applied to fabric with heat and pressure. |

| Advantages | 1. Vivid Colors 2. Durability 3. Flexibility for small and large orders |

| Essential Tools | 1. DTF Printer 2. Special Inks 3. Powder Adhesive 4. Heat Press |

| Successful Tips | 1. Adjust printing settings 2. Ensure even adhesive application 3. Use proper heat press techniques 4. Follow post-transfer care instructions |

Summary

DTF transfers are quickly becoming a popular choice among apparel decorators, offering unique advantages over traditional printing techniques. This method not only produces vibrant and durable designs but also adds flexibility for both hobbyists and businesses. By understanding the intricacies of DTF printing, including the necessary tools, techniques, and care instructions, you can fully harness the potential of this innovative approach. The future of apparel decoration looks bright with DTF transfers leading the charge in customization and quality.