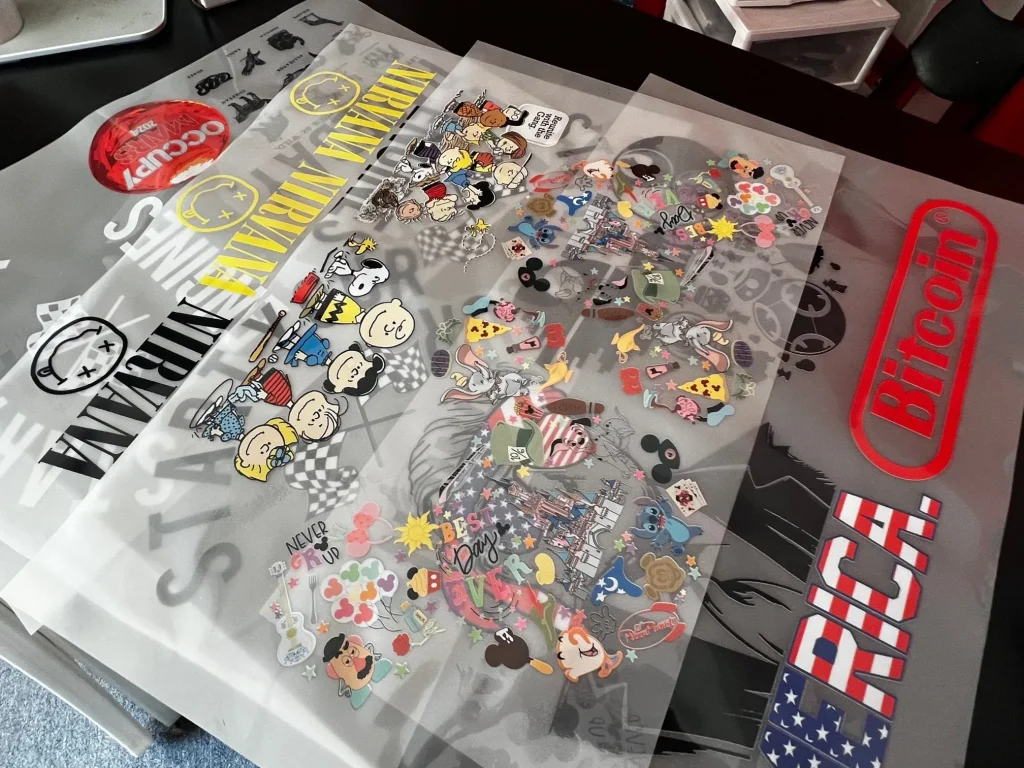

DTF gangsheet is revolutionizing the world of custom apparel production, becoming an essential tool for designers and printers alike. This innovative method, known for its versatility and efficiency, allows creators to print multiple images on a single sheet, optimizing both time and resources. With the rise of Direct-to-Film printing, understanding how to effectively design a gangsheet is crucial for achieving high-quality results. By mastering elements such as layout optimization and material selection, you can create stunning apparel that stands out in today’s competitive market. In this guide, we’ll delve into the best practices for crafting the perfect DTF gangsheet, including tips for utilizing the right DTF materials and enhancing your printing technique.

In the realm of Direct-to-Film (DTF) printing, a gangsheet serves as a pivotal component in the efficient production of custom apparel. By harnessing techniques that allow for the simultaneous printing of various designs, this approach not only saves valuable time but also maximizes material usage. Known by various names such as gang sheet printing and multi-design layouts, the concept focuses on creating an optimized design that can be easily transferred onto garments using specialized films. Understanding how to create an effective gangsheet design is essential for anyone looking to delve deeper into the DTF printing process, ensuring that every design is represented beautifully and accurately.

What is DTF Printing?

Direct-to-Film (DTF) printing is an innovative technique that has revolutionized the custom apparel production industry. By utilizing high-quality inkjet printers, designs are first printed onto a specialized film. This process allows for vibrant colors and intricate details, making DTF printing particularly appealing for custom garments. As a versatile printing method, DTF can be applied to a variety of fabrics, thus broadening the scope of creative possibilities for designers.

Moreover, DTF printing stands out due to its user-friendliness. Even those new to the custom apparel space can quickly grasp the basic process and start producing high-quality prints. One of the key benefits of DTF is the ability to print designs in bulk, further reducing costs and increasing efficiency. This adaptability makes DTF printing a sought-after choice among both hobbyists and professional printers.

The Importance of Gangsheet Design

Gangsheet design is a crucial aspect of the DTF printing process that directly impacts production efficiency. By arranging multiple designs onto a single sheet, businesses can optimize material usage and maximize their output. A meticulously planned gangsheet layout ensures that there is minimal wasted space, allowing for cost-effective printing. Additionally, proper spacing between designs prevents any overlapping during the transfer process, ensuring clean and distinct prints on each garment.

When designing a gangsheet, it’s essential to consider the dimensions of each individual design. Adjustments might be necessary to fit them all within the constraints of the transfer film. Utilizing software tools that specialize in gangsheet layouts can empower printers to visualize their designs and optimize their placement. Ultimately, this strategic planning leads to a smoother printing experience and a more effective use of DTF materials.

Essential DTF Materials and Their Impact

Selecting the right materials is paramount in achieving high-quality DTF prints. The transfer film plays a vital role in ensuring durability and vibrancy of colors. In 2024, numerous innovations in DTF materials have emerged, including films designed to enhance adhesion and improve wash resistance. Printers must stay informed about these developments to select the best options for their projects, which can significantly elevate the overall quality of the custom apparel produced.

Additionally, the type of adhesive used in DTF printing can affect the longevity and resilience of the prints. Combining advancements in film technology with high-quality adhesives can lead to satisfactory results that will endure the test of time. Therefore, understanding the best DTF materials and selecting them wisely is key to producing exceptional and lasting printed apparel.

Optimizing DTF Printer Settings

The printer settings used during the DTF printing process can greatly impact the quality of the final product. Adjustments to ink density, print speed, and temperature settings are crucial for achieving optimal results. For instance, a higher ink density may be necessary for vibrant color output, while the speed of printing should be finely tuned to ensure that every detail of the design is captured accurately.

Additionally, comprehending the specific characteristics of the printer being used for DTF printing is vital. Calibration can help printers attain the best performance from their printer, maximizing efficiency. Regularly reviewing and adjusting printer settings in line with advancements in DTF technology ensures consistently high-quality prints, yielding vibrant colors and intricate details in every project.

Innovations Transforming DTF Printing

The DTF printing industry is in a state of continuous evolution, with new innovations frequently emerging that aim to enhance the printing process. Recent developments include films that facilitate easier peeling and improved color vibrancy, which is important for creating eye-catching custom apparel designs. These advances not only improve the user experience but also play a significant role in the quality of the final products.

Moreover, as sustainability becomes increasingly important, manufacturers are now focusing on producing eco-friendly inks and materials. Incorporating sustainable practices within the DTF printing process not only appeals to environmentally conscious consumers but also positions businesses favorably in a competitive market. Embracing these innovations can give brands a distinct advantage while also supporting greener production methods.

Resources for Continuous Learning in DTF Printing

For those eager to deepen their understanding of DTF printing and gangsheet design, a wealth of educational resources is available. Platforms like Printful offer comprehensive guides designed for both beginners and experienced professionals. These resources delve into the complexities of creating effective DTF gangsheet designs and provide essential tips to enhance the overall printing process.

Furthermore, DTF Superstore specializes in beginner-friendly resources that break down the use of various DTF materials. They offer step-by-step tutorials that can help novices quickly grasp the concepts needed to start printing successfully. Engaging with such educational platforms allows practitioners to stay updated with industry trends and continuously improve their skills, helping them thrive in the evolving custom apparel market.

Frequently Asked Questions

What is a DTF gangsheet and how does it work in custom apparel production?

A DTF gangsheet is a design layout used in Direct-to-Film (DTF) printing that allows multiple designs to be printed on a single sheet simultaneously. This method optimizes the use of materials and streamlines the printing process, making it ideal for custom apparel production.

How can I design an effective DTF gangsheet layout?

To design an effective DTF gangsheet layout, arrange designs to minimize gaps and ensure they remain distinct to avoid overlapping during transfer. Utilizing layout optimization software can help visualize and refine your design arrangement before printing.

What materials are necessary for successful DTF gangsheet printing?

Successful DTF gangsheet printing requires specific materials, including high-quality transfer films and adhesive. Staying updated with the latest DTF materials is crucial, as innovations can enhance adhesion and durability of the prints.

What are some common mistakes to avoid when creating a DTF gangsheet?

Common mistakes when creating a DTF gangsheet include using low-resolution images, neglecting color profile settings, and poor layout planning. Always ensure high-resolution files and proper arrangements to optimize the printing process.

How do I set up my printer for optimal DTF gangsheet results?

To achieve optimal results for DTF gangsheet printing, adjust your printer settings for ink density, print speed, and temperature specific to your equipment. Understanding your printer’s capabilities is key to calibrating the settings appropriately.

Where can I find resources to learn more about DTF printing and gangsheet design?

Resources for learning more about DTF printing and gangsheet design include blogs from platforms like Printful, tutorials on DTF Superstore, and industry news from Graph-Tech and Fespa. These platforms offer valuable insights and updates in the DTF printing sector.

| Key Aspect | Details |

|---|---|

| DTF Printing Overview | DTF printing is a user-friendly method that allows vibrant and intricate designs to be printed on various fabrics. |

| Design Layout Optimization | Proper arrangement of multiple designs minimizes material waste while avoiding overlaps. |

| File Preparation | High-resolution images and correct color profiles (RGB to CMYK) are essential for quality. |

| Material Selection | Choosing the right transfer film and adhesives is crucial for the durability and quality of prints. |

| Printer Settings | Adjusting settings like ink density and print speed is essential for optimal results. |

| Recent Innovations | New materials improve peeling ease and color vibrancy, enhancing the user experience. |

| Sustainability Practices | Focus on eco-friendly inks and materials can attract environmentally conscious consumers. |

| Educational Resources | Platforms like Printful and DTF Superstore offer guides and tutorials for DTF printing. |

Summary

DTF gangsheet is a vital component in the world of custom apparel, providing creators with an efficient method to streamline production. Understanding the nuances of DTF printing, from design considerations to material choices, is essential for anyone looking to excel in this field. The importance of layout optimization and proper file preparation cannot be understated, as they significantly influence the quality and durability of the prints. As the DTF printing industry continues to evolve with sustainable practices and innovative materials, creators should remain informed and adaptable. By leveraging available educational resources, one can master the art of creating the perfect DTF gangsheet and remain competitive in the ever-growing custom apparel marketplace.