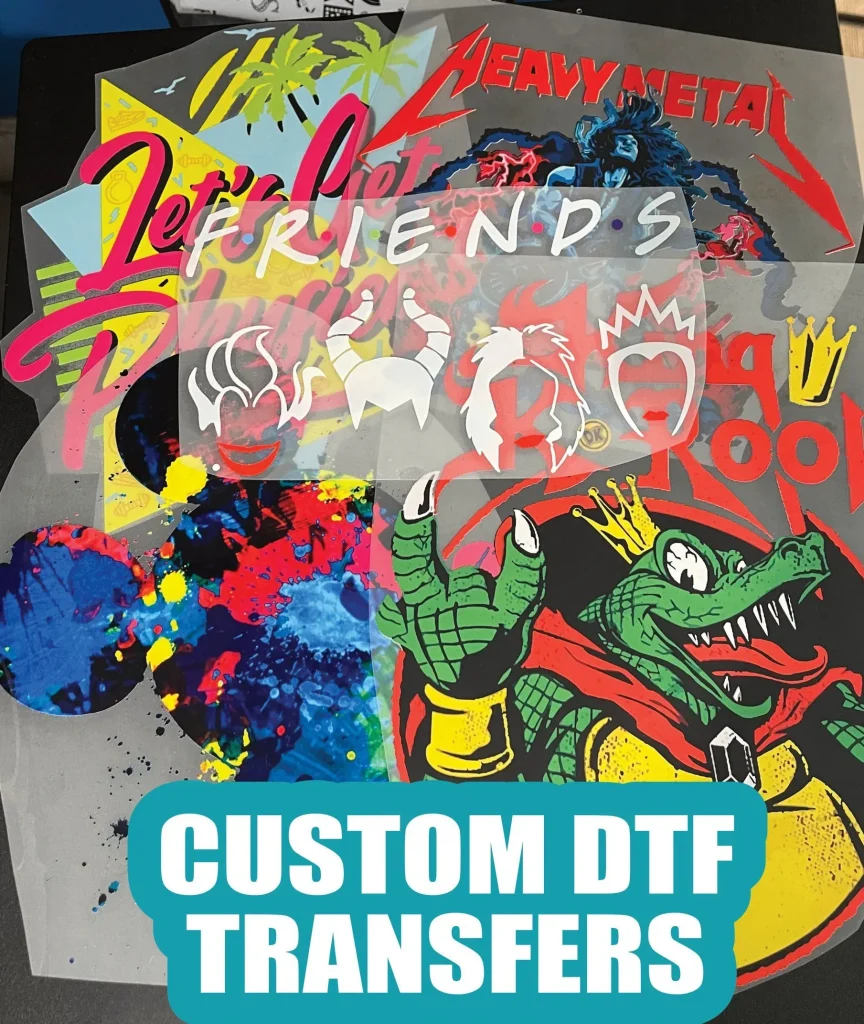

In the ever-evolving printing industry, DTF transfers are making a significant impact by providing an innovative approach to custom apparel printing. Direct-to-Film (DTF) transfers utilize a unique process that allows for vibrant, high-quality prints on various fabric types, making them an attractive option for both professionals and hobbyists. This method stands out not only for its efficiency but also for its versatility compared to traditional techniques like DTF printing and Direct-to-Garment (DTG). As more businesses recognize the advantages of DTF transfers, including cost-effectiveness and ease of use, the method is rapidly gaining popularity. In the following sections, we will explore the DTF transfer process and its numerous benefits, further highlighting why this technique is revolutionizing custom printing.

The world of printing is witnessing a transformative shift with the emergence of Direct-to-Film (DTF) technology, a method that enhances the realm of personalized fabric designs. This cutting-edge printing approach allows users to transfer intricate graphics directly onto textiles, offering a superior resolution and color vibrancy. By leveraging the shortcomings of conventional techniques such as Direct-to-Garment (DTG) and screen printing, DTF printing presents a compelling alternative for those involved in custom apparel production. The transformative DTF process combines efficiency and adaptability, making it a favorite among both small business owners and creative enthusiasts alike. As consumer demand for unique and high-quality printed items grows, understanding the nuances of DTF transfer will be essential for those looking to thrive in this dynamic marketplace.

Understanding the Benefits of DTF Printing

DTF printing stands out for its ability to create high-quality prints that are both vibrant and durable, making it a favorite among those in the custom apparel market. What sets DTF transfers apart is their capacity to produce intricate designs that maintain color fidelity and detail, regardless of the fabric texture. This process allows for detailed graphics that are particularly appealing for promotional items or unique fashion pieces.

Additionally, the versatility of DTF transfers plays a significant role in their popularity. DTF can be applied to a wide range of fabrics, including cotton, polyester, and blends, allowing creators to experiment with various materials without compromising on quality. Furthermore, this adaptability has made DTF a preferred method for many businesses looking to expand their product offerings beyond the limitations of traditional printing methods.

The DTF Transfer Process Demystified

Understanding the DTF transfer process is essential for anyone looking to utilize this technology effectively. The method starts with the creation of a digital design that is then printed onto a specialty coated film using high-quality DTF printers. It’s important to note that the choice of ink can significantly affect the vibrancy and longevity of the final product, emphasizing the need for quality materials throughout the printing process.

After the design is printed, a hot-melt adhesive is applied to the film, allowing for a secure transfer to fabric during the heat application. Using a heat press, the film is heated and pressed against the chosen fabric, activating the adhesive. As the film cools, the design adheres firmly to the fabric, resulting in a crisp, bright print that can endure multiple washes. This straightforward yet effective process has contributed to DTF’s rising popularity.

DTF Transfers vs. DTG Printing: A Comprehensive Comparison

When comparing DTF printing to Direct-to-Garment (DTG) printing, several differences emerge that can influence users’ choices. While both methods aim to provide high-quality prints, DTF has a notable advantage in terms of its suitability for various fabric types without the necessity of pre-treatment. In contrast, DTG requires fabric pre-treatment to achieve the best results, making the DTF process faster and less resource-intensive.

Moreover, for small run productions, DTF tends to prove more cost-effective than DTG. This aspect significantly benefits small businesses that may not have the demand for larger print quantities. While DTG can produce stunning photographic imagery, DTF excels in reproducing intricate graphics with bold colors, making it an ideal choice for custom apparel that demands high visual impact.

Market Trends: The Growth of DTF Transfers

The DTF transfer market is witnessing unprecedented growth as the demand for custom apparel surges in various retail sectors. Fashion, sports, and promotional merchandise industries are increasingly adopting DTF technology, drawn in by its flexibility and ability to provide high-quality outputs. This alignment with contemporary market trends signifies DTF’s role as an essential player in the custom printing landscape.

Moreover, the emergence of small businesses and startups adopting DTF for customized printing solutions is propelling this sector’s expansion. As more entities leverage DTF to meet consumer demands for personalized products, the technology’s market presence continues to strengthen, highlighting its strong potential in redefining the future of apparel printing.

Challenges to Consider with DTF Transfers

Despite the many advantages of DTF printing, there are certain challenges that businesses should navigate. One key hurdle is the technical knowledge required to achieve consistent, high-quality results. New users might experience a learning curve as they familiarize themselves with the nuances of DTF technology, from design creation to final producing techniques.

Additionally, the initial investment needed for DTF printers and heat presses can be daunting for some businesses. However, while equipment costs can be high, the understanding of equipment maintenance and strict quality control can mitigate longer-term costs associated with poor-quality prints. Balancing these factors is crucial to guarantee optimal returns on investment in DTF technology.

The Environmental Impact of DTF Printing

One of the lesser-known benefits of DTF printing is its reduced environmental impact compared to traditional printing methods, such as screen printing. DTF uses water-based inks that are less harmful and promote sustainability—this environmentally friendly aspect resonates well with consumers who increasingly prioritize eco-conscious products. Becoming a more sustainable choice not only benefits the planet but also appeals to a broader range of customers.

As businesses look to differentiate themselves in a crowded market, promoting sustainability through DTF printing might just be the unique selling point that sets them apart. By embracing newer, greener technologies, companies can not only satisfy consumer demand for sustainability but also enhance their brand image, leading to potentially increased market share.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that involves printing a design onto a specially coated film, which is then transferred onto fabric using a heat press. This DTF transfer process produces high-quality, vibrant prints that adhere to various materials, making it an ideal choice for custom apparel printing.

What are the advantages of DTF transfers over other printing methods?

The advantages of DTF transfers include high-quality prints with vibrant colors, versatility across multiple fabric types, cost-effectiveness for small runs, and no need for pre-treatment of fabrics—unlike Direct-to-Garment (DTG) printing. Additionally, DTF printing utilizes eco-friendly water-based inks, aligning with sustainable practices.

How does DTF printing compare to DTG in terms of quality and cost?

DTF printing generally offers excellent quality, particularly for intricate designs and vibrant colors on various fabrics. While DTG printing is also high-quality, it may have higher initial costs due to necessary pre-treatment equipment. DTF is often more economical for smaller print runs, making it an attractive option for custom apparel.

What is the DTF transfer process step by step?

The DTF transfer process involves several key steps: 1) Design creation using graphic software, 2) Printing the design onto DTF film with a specialized printer, 3) Applying a hot-melt adhesive, 4) Using a heat press to transfer the design onto fabric, and 5) Peeling the film away to reveal the finished print.

Are DTF transfers environmentally friendly compared to traditional printing methods?

Yes, DTF transfers are considered more environmentally friendly than some traditional printing methods because they utilize water-based inks. This reduces the impact on the environment as opposed to solvent-based inks used in traditional processes, appealing to consumers who prioritize sustainability in custom apparel printing.

Can DTF transfers be used on any type of fabric?

DTF transfers are highly versatile and can be used on a wide range of fabrics, including cotton, polyester, and blended textiles. This adaptability makes DTF a preferred choice for various applications in custom apparel printing, ensuring vibrant prints on diverse materials.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers revolutionize custom printing by allowing high-quality prints on various materials, especially textiles. |

| Definition | DTF transfers print designs onto coated film and then use heat to transfer them to fabric, achieving vibrant, durable results. |

| Advantages | 1. High-quality prints with intricate designs. 2. Versatile across various fabrics. 3. Cost-effective for small runs. 4. No pre-treatment required. 5. Uses eco-friendly water-based inks. |

| Process | Involves design creation, printing on film, applying adhesive, heat transfer to fabric, and final cooling. |

| Comparison with Other Techniques | Compared to DTG and screen printing, DTF has lower costs for small prints, versatile print quality, and faster production for custom orders. |

| Market Growth | DTF transfers are seeing rising adoption in retail sectors, particularly fashion and promotional merchandise, driven by small business demand. |

| Challenges | Requires technical knowledge, significant initial equipment costs, and rigorous quality control to ensure high output. |

Summary

DTF Transfers have emerged as a transformative solution in the realm of custom printing, offering exceptional quality and versatility for fabric applications. As businesses and individuals alike seek innovative ways to create personalized apparel, DTF transfers are increasingly recognized for their ability to produce intricate and vibrant designs. This method not only streamlines the printing process by eliminating pre-treatment steps but also supports eco-friendly practices with its use of water-based inks. The growing demand for custom products positions DTF transfers as a key player in the future of the printing industry, making it essential for businesses to adopt and embrace this technology.