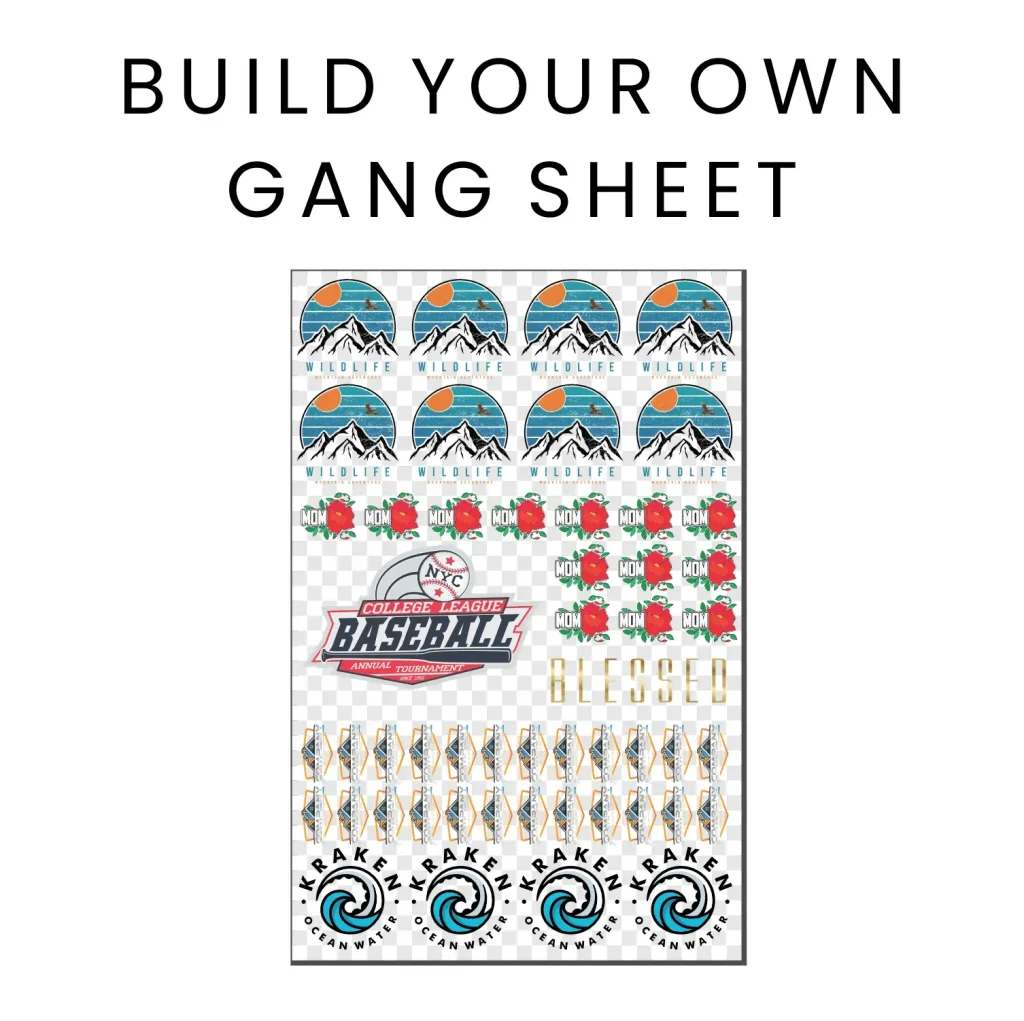

In the rapidly evolving landscape of printing, the DTF Gangsheet Builder stands out as a revolutionary tool that enhances the creative process for printers and designers alike. By utilizing DTF printing techniques, this innovative builder allows for the simultaneous printing of multiple designs, optimizing efficiency while maintaining exceptional DTF print quality. Gone are the days of tedious single prints; with gang sheet printing, you can push the boundaries of design optimization, achieving vibrant and detailed results on fabric. Moreover, as the industry shifts towards sustainability, the eco-friendly DTF printing options provided by such builders ensure that quality never compromises environmental responsibility. Whether you are a seasoned professional or a novice, the DTF Gangsheet Builder is your gateway to creating stunning and resource-efficient prints.

Exploring the realm of Direct to Film (DTF) printing unveils an array of innovative solutions, particularly through the use of a gangsheet creator. This advanced technology not only streamlines the printing workflow but also enables designers to maximize their output by combining various artwork pieces into a single transfer sheet. With an emphasis on design enhancement and efficient printing processes, these tools cater to the demands of creators seeking precision and vibrancy in their fabric prints. As businesses increasingly prioritize eco-conscious methods, utilizing an eco-friendly approach within DTF methodologies has become paramount, further enriching the realm of personalized printing. By understanding these dynamic printing methods and their potential, artists can craft visually arresting projects while championing sustainability.

Maximizing DTF Print Quality with Proper Technique

To achieve the highest quality in DTF printing, adopting the right techniques is essential. It begins with understanding the specifics of DTF print quality, which not only includes vibrant color reproduction but also durability on various fabrics. The resolution of your designs plays a critical role; a resolution of 300 DPI ensures clarity and precision in the printed output. Furthermore, utilizing vector graphics allows for scalability, meaning your designs won’t lose quality when resized. This is particularly important for intricate designs where details are crucial.

Additionally, consistent testing is key to mastering DTF print quality. Regularly conducting test prints on different substrates will provide insight into how ink responds on various materials. It is advisable to monitor the curing temperatures and times, as these directly affect the adhesion of the transfer to the fabric. With each test, adjustments can be made to ink density and print speed to find the perfect balance that delivers outstanding results.

Effective DTF Design Optimization Techniques

Design optimization is a fundamental step when utilizing the DTF Gangsheet Builder. The goal here is to ensure that the designs are not only visually appealing but also functionally efficient when printed. This involves choosing the right color palettes that translate well into vibrant prints. Colors can appear differently when printed on fabric, so selecting hues with a matching profile can greatly enhance the outcome. Using design software, it’s wise to print mock-ups to identify any potential issues before finalizing designs.

Moreover, the arrangement of designs on the gang sheet plays a vital role in maximizing the use of space and reducing waste materials. By strategically placing designs to minimize gaps and overlap, you can optimize ink usage and cost efficiency. Proper layering of designs can also minimize the need for alterations during the transfer process, making it an intuitive practice to follow for every DTF printing project.

The Essential Role of File Preparation in DTF Printing

File preparation is a critical component of the DTF printing process that significantly affects the transfer quality. Converting images to suitable formats such as PNG or TIFF, especially with transparent backgrounds, ensures that designs are rendered with clarity during the transfer. This step is crucial as it maintains the integrity of the artwork and avoids pixelation when designs are enlarged. Furthermore, keeping an organized file structure will aid in quick access during the printing process.

In addition to format selection, it’s important to check color profiles before printing. Using an RGB color profile can sometimes yield better results, matching the colors as they will appear in print. Additionally, reducing the number of layers in the artwork can streamline the transfer process, as fewer layers mean less complexity during application. This leads to higher quality outcomes for intricate designs.

Exploring Eco-Friendly DTF Printing Solutions

As the printing industry evolves, eco-friendly DTF printing solutions are gaining traction. Many businesses are seeking ways to reduce their environmental footprint by incorporating sustainable practices into their operations. This includes using eco-friendly inks and films that not only appeal to environmentally conscious consumers but also maintain high-quality print results. It’s essential to stay updated with suppliers that offer sustainable materials, ensuring that your printing practices align with current trends.

Utilizing eco-friendly DTF practices can also enhance your brand’s image. Customers increasingly prioritize sustainability in their purchasing decisions, leading to a competitive advantage for those who adopt green practices. Moreover, embracing eco-friendly processes often leads to innovations that can improve operational efficiency, such as reduced waste during production and lower energy consumption, further benefitting both the business and the environment.

Mastering the Transfer Process for Optimal Results

The transfer process is the culmination of all the efforts put into DTF printing, and mastering it can significantly impact the overall quality of the final product. One essential tip is to apply the adhesive powder while the ink is still wet; this ensures a strong bond between the film and fabric during the heat application phase. It’s also crucial to maintain consistent heating during the curing process, avoiding fluctuations that can compromise the adhesion quality.

Testing these settings on samples can provide insights into how different materials respond to various temperatures and times. Since fabrics can vary in texture and thickness, calibrating your heat settings for each type of textile will enhance the effectiveness of the transfer. By investing time into perfecting this process, you ensure that designs are not only vibrant but also durable, standing up to wear and wash while retaining their integrity.

Choosing the Right Software for DTF Printing

In today’s digital age, selecting the right software for DTF printing can streamline the design process significantly. Various software options are tailored specifically for DTF, providing unique features that enable easier manipulation and organization of designs when preparing gang sheets. Software such as Adobe Photoshop remains popular due to its robust layering options, while specialized DTF software often includes pre-configured settings that optimize designs for print efficiency.

When working with software, take advantage of tools that allow grouping multiple designs into a single file effectively. Features like grid layouts and automatic alignment capabilities ensure that your designs are printed efficiently without wasting material. Investing time in learning the software’s capabilities can lead to creative exploration and ultimately yield stunning prints that stand out in the marketplace.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how is it used in DTF printing techniques?

The DTF Gangsheet Builder is a tool that allows users to efficiently create gang sheets for Direct to Film (DTF) printing. By laying out multiple designs on a single film transfer, it enhances production efficiency, reduces material waste, and allows for vibrant and high-quality prints, making it popular among printers.

How can I optimize my designs for the DTF Gangsheet Builder to improve DTF print quality?

To optimize your designs for the DTF Gangsheet Builder, ensure they are created at a resolution of 300 DPI and use vector graphics where possible. This maintains clarity and sharpness. Additionally, consider color profiling and layout designs that fit well on the gang sheet to enhance DTF print quality.

What file formats are best for use with DTF Gangsheet Builder in DTF printing?

The best file formats for DTF Gangsheet Builder are PNG or TIFF, as these formats support transparent backgrounds and preserve image quality. Ensuring that files are appropriately prepared will contribute to the overall success of the DTF printing process.

What transfer process should I follow for DTF printing with a gang sheet using the DTF Gangsheet Builder?

For a successful transfer after printing with the DTF Gangsheet Builder, apply a powder adhesive to the wet ink and cure it using heat at approximately 160-180°C for 10-20 seconds. This ensures strong adherence of your designs to the fabric, resulting in high-quality outputs.

Are there eco-friendly options available in DTF printing when using a DTF Gangsheet Builder?

Yes, many DTF printing operations are adopting eco-friendly DTF inks and films. By using sustainable materials, printers not only comply with environmental standards but also attract eco-conscious consumers. Incorporating these options into your printing process can enhance your brand reputation.

Can I use popular software for DTF printing with the DTF Gangsheet Builder to streamline my workflow?

Absolutely! Software like Adobe Photoshop and specialized DTF printing applications can help streamline the design and layout process for gang sheets. These tools offer features that aid in optimizing multiple designs to fit well on a single print, improving both quality and efficiency.

| Key Points | Details |

|---|---|

| DTF Printing | Direct to Film (DTF) printing offers vibrant colors and durability by transferring designs from a special film to fabric using heat. |

| Gang Sheets | Using gang sheets allows for multiple designs to be printed simultaneously, increasing efficiency and reducing waste. |

| Design Optimization | Ensure designs are at least 300 DPI for clarity and use vector graphics to avoid pixelation. |

| File Preparation | Use PNG or TIFF formats with transparent backgrounds to maintain quality during transfers. |

| Printer Settings | Adjust printer settings specifically for DTF, conducting test prints to calibrate before production. |

| Transfer Process | Apply adhesive while ink is wet and cure with heat (160-180°C for 10-20 seconds) for strong adherence. |

| Popular Software | Use dedicated DTF software or applications like Adobe Photoshop for optimizing gang sheet designs. |

| Sustainability Trends | There’s a growing emphasis on eco-friendly inks and films in DTF printing to appeal to conscious consumers. |

Summary

DTF Gangsheet Builder is an essential tool for mastering the art of DTF printing, empowering users to create high-quality prints efficiently. By employing the recommended techniques, such as optimizing your designs and mastering the transfer process, you’re not only enhancing the aesthetic quality of your products but also streamlining your production workflow. As the DTF printing method continues to evolve with new software and sustainable practices, it’s vital to stay informed on best practices to maintain a competitive edge. Ultimately, leveraging the DTF Gangsheet Builder opens up a world of possibilities for elevating your print projects, making them more vibrant and durable for your clients.