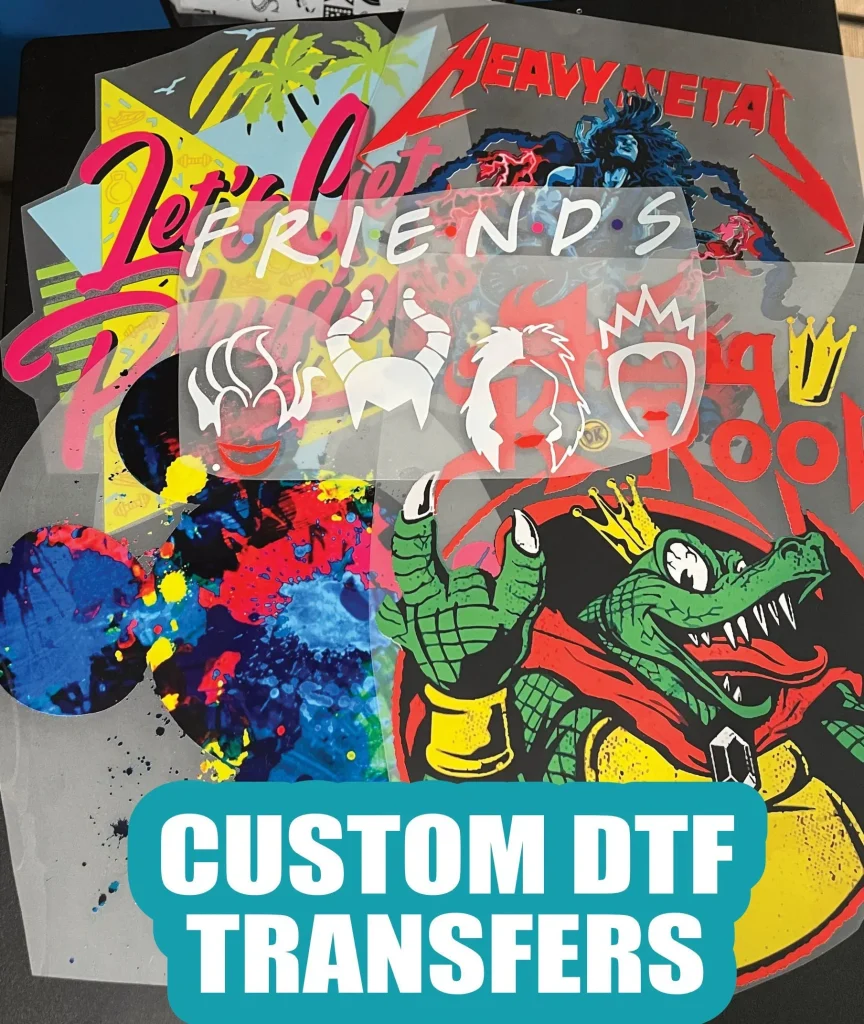

DTF transfers, or Direct-to-Film transfers, represent a revolutionary leap in the world of custom printing solutions, capturing the essence of modern printing technology. This innovative method enables designers and manufacturers to transfer high-quality images directly onto fabrics with remarkable ease and precision. As the DTF printing technology continues to evolve, it showcases a significant growth trajectory that aligns with the increasing consumer demand for personalized and unique garments. Businesses are turning towards sustainable printing practices, and DTF is leading the charge with eco-friendly options that appeal to environmentally conscious consumers. In this blog, we will explore how DTF transfers are reshaping the printing industry and what the future holds for this dynamic technology.

Direct-to-Film transfer methods, often referred to as DTF technology, offer a fresh perspective in the realm of fabric printing. This advanced technique allows for intricate designs to be printed onto a special film before being applied to different textile surfaces, paving the way for vibrant, durable prints. As the market for custom printing continues to expand, DTF printing solutions emerge as a frontrunner, proving essential for businesses seeking sustainable and efficient production methods. The growing popularity of personalized products has significantly influenced the DTF market growth, making this technology a staple in the competitive landscape of textile printing. This introduction to DTF will shed light on its immense potential and adaptability across various applications.

The Evolution of Direct-to-Film Printing

Direct-to-Film (DTF) printing has evolved remarkably since its inception, transitioning from a niche printing solution to a widely adopted method among textile manufacturers and graphic designers. This evolution can be attributed to several factors, including advancements in printing technology and the increasing consumer demand for customization. Today, DTF printing operates with sophisticated machinery that allows for high-quality and intricate designs to be effortlessly transferred onto various fabrics, ensuring durability and vibrancy in the output.

Furthermore, the appeal of DTF lies in its ability to cater to a wide array of materials beyond traditional fabrics. As designers and brands seek innovative ways to present their art and messages, DTF technology continues to adapt, ensuring that it meets the diverse needs of the market. This adaptability signals a strong future for DTF printing, showing that it is not merely a transitional phase but rather a robust solution in the textile printing landscape.

The Impact of DTF Printing on Customization Trends

The rise of DTF printing has fundamentally transformed the landscape of customization in apparel and promotional products. As consumers increasingly desire unique and personalized items, DTF technology provides an efficient means to fulfill these desires. With its capacity for high-resolution designs and vibrant colors, businesses can respond effectively to customer demands for individualized fashion and branded merchandise, ultimately fostering greater customer loyalty.

Moreover, as brands embrace DTF transfers in their production workflows, they find themselves positioned at the forefront of a burgeoning market. The ability to offer tailor-made solutions within short turnaround times nurtures a competitive edge, enabling brands to respond to trends and seasonal changes rapidly. This capability not only satisfies the aesthetic needs of consumers but also creates an intimate connection between the brands and their customers, solidifying long-lasting relationships.

Technological Advancements in DTF Printing

The technological advancements in DTF printing have been a game-changer for businesses striving for efficiency and quality. With innovations in printer design and ink formulation, DTF technology now boasts superior color accuracy and durability, setting it apart from traditional methods. These enhancements ensure that prints are not only visually appealing but also withstand the rigors of daily use, meeting the high standards set by today’s consumers.

Additionally, the streamlining of DTF production processes means shorter lead times and higher throughput, making it easier for businesses to meet growing demand. As printer manufacturers continue to innovate and enhance DTF technology, users can expect to see even greater improvements in workflow efficiencies, further solidifying DTF’s pivotal role in the future of the printing industry.

Sustainability Practices in DTF Printing

Sustainability is no longer an afterthought in business operations; it is becoming a central pillar of branding. DTF printing, with its adoption of water-based inks and eco-friendly practices, represents a significant step towards greener manufacturing processes in the textile industry. As brands increasingly seek to align themselves with sustainability goals, the low environmental impact of DTF technology positions it as a leading alternative to more traditional, harmful printing methods.

In response to consumer demand for responsible practices, DTF manufacturing not only supports sustainable initiatives but also enhances a brand’s reputation. Companies that adopt eco-conscious technologies like DTF printing demonstrate a commitment to environmental stewardship, which resonates strongly with today’s environmentally aware consumers, ultimately leading to higher engagement and brand loyalty.

User Adoption Trends in DTF Technology

The democratization of DTF technology is reshaping the custom printing landscape, with small and medium-sized enterprises (SMEs) increasingly leading the charge. Lower startup costs and simplified operational processes make DTF printing an attractive option for new businesses looking to enter the market. The flexibility and ease of use available with DTF printers allow these businesses to offer personalized products without the considerable overhead traditionally associated with custom printing.

Moreover, established companies are also pivoting towards DTF technology as they seek to diversify their offerings and streamline production. The adaptability of DTF integrates seamlessly with existing operations, allowing veteran businesses to adapt quickly to market demands. This trend towards broader user adoption signifies not only a shift in printing strategies but also a collective movement towards leveraging technology for greater creativity and efficiency in the custom printing sector.

Expanding Applications of DTF Transfers

DTF printing is carving out new applications beyond its roots in apparel manufacturing, demonstrating remarkable versatility. As different industries explore DTF technology, new markets are being uncovered, including home textiles and promotional products. The ability to produce customized items like cushion covers, bags, and wall art showcases how DTF can adapt to various consumer needs, making it a comprehensive printing solution for designers looking to diversify their portfolios.

As new applications are discovered, the ongoing growth of the DTF market indicates a promising future. Whether it’s creating unique home decor or custom-branded merchandise, businesses can leverage DTF printing to meet varied customer preferences. This flexibility not only reinforces DTF’s role in the contemporary marketplace but also sparks creativity in product design, empowering brands to innovate continuously and cater to evolving consumer demands.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technology that involves printing designs onto a specialized film, which is then transferred onto fabric using heat. This innovative method allows for high-quality and durable prints on various textiles, making it an excellent option for customized apparel and products.

Why is DTF printing technology gaining popularity in the custom printing solutions market?

DTF printing technology is rapidly gaining popularity due to its ability to produce intricate designs with vibrant colors and durability. As consumers increasingly demand personalized products, the versatility of DTF transfers meets this need, positioning it as a favored choice over traditional printing methods.

What are the sustainability benefits of DTF transfers?

DTF transfers promote sustainability through the use of water-based inks, which reduce harmful emissions compared to traditional printing methods like screen printing. This eco-conscious approach aligns with consumer expectations for environmentally responsible practices, making DTF an attractive and sustainable option for brands.

How is the DTF market expected to grow in the coming years?

The DTF market is projected to grow significantly, with forecasts suggesting it could surpass $800 million by 2030. This growth is driven by an increasing demand for customized apparel and the adoption of innovative printing technologies that enhance quality and efficiency.

What advantages do DTF transfers offer over traditional printing methods?

DTF transfers offer several advantages, including faster setup times, lower production costs, and the ability to print on a wide range of fabrics. Additionally, DTF technology delivers excellent color accuracy, wash durability, and the flexibility to produce tailored designs on demand, appealing to both brands and consumers.

In what industries are DTF transfers proving to be beneficial besides apparel?

Beyond apparel, DTF transfers are increasingly utilized in home textiles, promotional products, and specialty canvas prints. Their versatility enables designers to expand into new markets, creating unique items like custom cushion covers and branded merchandise, showcasing DTF’s wide-ranging applications in the custom printing landscape.

| Key Area | Description |

|---|---|

| Understanding DTF Technology | DTF printing offers versatility, durability, and efficiency across multiple fabrics, allowing for intricate designs and high-quality prints. |

| Market Growth | The DTF printing market is projected to exceed $800 million by 2030, driven by increasing demand for customized apparel. |

| Demand for Customization | Consumers’ desire for personalized fashion boosts the adoption of DTF, benefiting businesses looking for unique offerings. |

| Technological Advancements | Innovations in ink quality and printer efficiency enhance DTF’s appeal, making it a preferred choice for high-quality output. |

| Sustainability | DTF printing employs water-based inks, significantly lowering emissions and aligning with consumer preferences for eco-friendly practices. |

| User Adoption Trends | SMEs adopt DTF due to lower costs and ease of use, making it attractive for new and established businesses. |

| Expanding Applications | DTF technology is expanding beyond apparel into home textiles and promotional products, enhancing its market versatility. |

Summary

DTF transfers are revolutionizing the world of printing, offering a compelling combination of versatility, sustainability, and widespread application across industries. As consumer preferences shift towards personalized and eco-conscious options, DTF technology is not just a passing trend, but a crucial component of the future of printing. With advancements in technology and a growing understanding of its benefits, businesses that incorporate DTF transfers can expect to thrive in an increasingly competitive market. This innovative printing method enables brands to offer customizable products while aligning with modern sustainability practices, ensuring its lingering presence in the textile industry.