DTF transfers, or Direct-to-Film transfers, have emerged as a game-changer in the world of textile printing, offering a unique blend of flexibility and vibrancy. This innovative technique allows designers to create intricate designs on a variety of fabrics, making it a favorite among apparel manufacturers and DIY enthusiasts alike. However, achieving successful DTF transfers requires meticulous attention to detail, as common mistakes can compromise transfer quality and lead to disappointing results. In this blog post, we’ll uncover essential DTF transfer tips to help you avoid pitfalls, from selecting the right materials to perfecting your DTF printing techniques. With these insights, you’ll be well on your way to producing stunning and durable prints that truly stand out.

When it comes to Direct Transfer Film applications, understanding the nuances of this modern printing technique is crucial. Utilizing an array of vibrant inks, filmmakers create stunning visuals that can be applied to various textile surfaces seamlessly. Yet, many users encounter hurdles that affect the overall effectiveness of their printed designs. This discussion will dive into the fundamental concepts and methodologies associated with effective transfers, equipping you with strategies to circumvent typical errors and enhance the quality of your outputs. From fabric selection to optimal printing conditions, master the art of producing beautiful textiles that leave a lasting impression.

Understanding DTF Transfers and Their Advantages

DTF transfers, or Direct Transfer Film transfers, represent a cutting-edge technology that has transformed the landscape of fabric printing. Utilizing a unique blend of high-quality inks and specialized transfer films, DTF printing allows for the application of intricate designs and vivid colors onto a wide variety of materials, from cotton to polyester. This versatility makes it a favored choice for designers looking to create unique apparel and other textile products. Understanding the chemistry behind DTF transfers can enhance your printing process, ensuring you harness the full potential of this innovative method.

The primary advantage of DTF transfers lies in their ability to achieve detailed and vibrant prints that are not only visually striking but also durable. Unlike traditional printing methods that may fade or crack over time, DTF prints maintain their integrity, offering longevity regardless of washing or exposure to elements. This appeal to permanence coupled with the ease of application positions DTF transfers as a highly sought-after option in the industry. Mastering this technique can elevate your textile projects, providing both aesthetic and functional benefits.

Common Mistakes in DTF Transfers to Avoid

When venturing into the world of DTF transfers, it is critical to steer clear of common mistakes that can ruin your projects. One prevalent error is selecting the wrong type of fabric that doesn’t allow for proper adhesion. For instance, high-polyester fabrics can lead to peeling and fading of designs. Instead, choosing materials like cotton or polyester blends enhances transfer quality, ensuring your prints stick well and look great for longer. To achieve the best results, always refer to DTF guidelines, as they highlight material compatibility.

Another mistake involves incorrect temperature and pressure settings during the transfer process. Many individuals either underestimate or overlook the importance of these parameters, leading to poor-quality prints or transfer failures. Each DTF film and fabric combination requires precise adjustments to achieve optimal bonding. Therefore, it’s advisable to consult with your DTF film manufacturer regarding recommended settings or conduct sample tests to determine the ideal settings for your unique projects.

Essential Tips for Successful DTF Transfers

Successful DTF transfers hinge on adhering to specific best practices that ensure your results are high-quality. Firstly, always initiate your project with high-resolution images; designs should be crisp and clear with a minimum resolution of 300 DPI. This quality in your artwork is foundational for achieving exceptional final prints. Ensuring that your images meet these standards will significantly enhance the clarity and vibrancy of your finished product.

Additionally, proper fabric preparation cannot be overstated. Before applying a DTF transfer, ensure that your fabric is clean and dry. Any remnants of dust, moisture, or oils can obstruct the transfer process, leading to diminished adhesion and compromised quality. Simple steps, like a quick wash or lint roll, can make a world of difference in ensuring your fabric is ready for the transfer, which ultimately affects the longevity and appearance of the print.

Mastering DTF Printing Techniques

To master DTF printing techniques effectively, one must stay informed on the latest advancements and troubleshooting strategies. Engaging with industry blogs, forums, and newsletters can provide valuable insights into effective practices and the latest innovations in DTF printing. Consistent learning ensures you stay ahead, allowing you to apply the best techniques that yield optimal results in your DTF transfers.

Moreover, testing before production is paramount. Conducting test runs allows you to verify if your temperature, pressure, and timing settings are aligned. This precaution minimizes the risk of material waste and ensures that your settings are conducive to a successful print. Analyzing the outcomes of your test transfers can lead to adjustments that refine your technique, ultimately enhancing your DTF transfer quality across larger production runs.

The Importance of Cooling Time in DTF Transfers

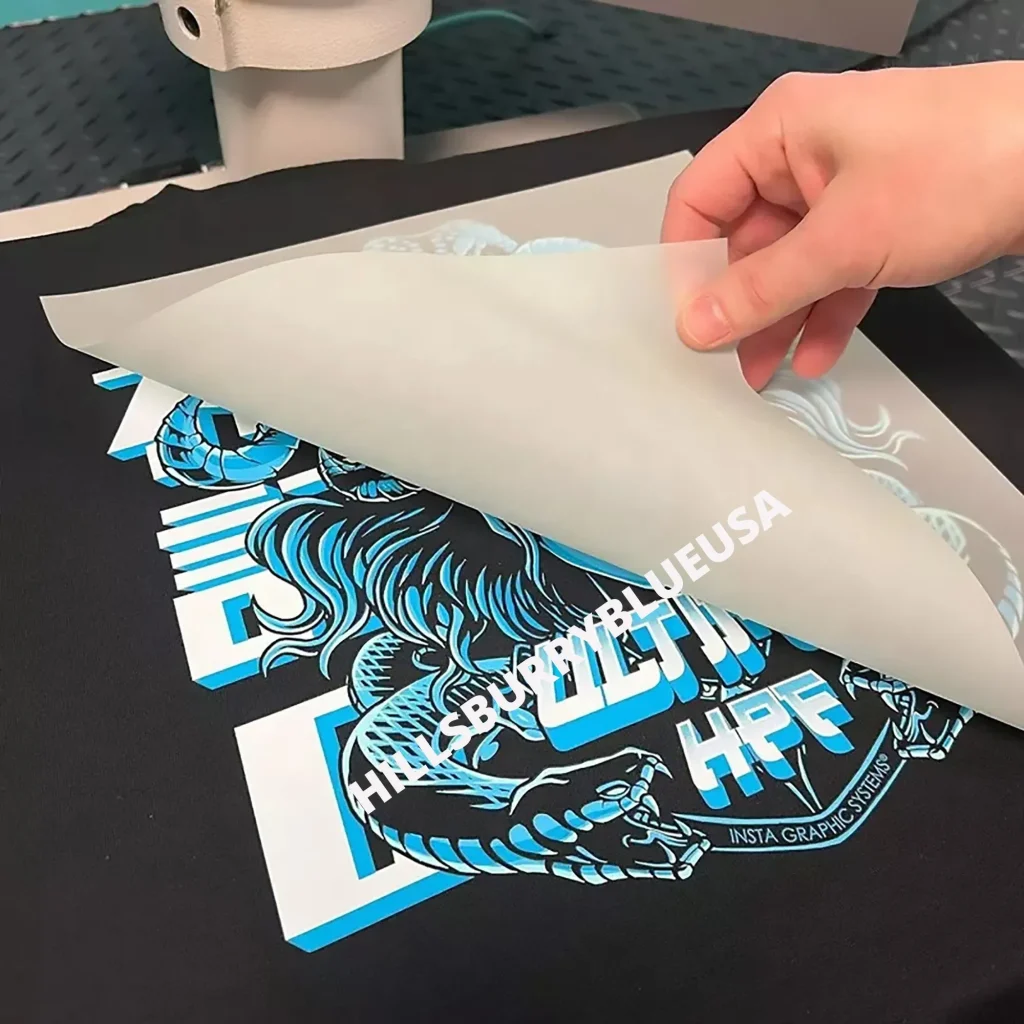

One crucial aspect that is often rushed in the DTF transfer process is the cooling time. The cooling phase is integral as it allows for the transfer to set and bond properly with the fabric. If you remove the transfer film too soon, it may lead to lifting or cracking of the printed design. Therefore, it’s essential to follow the manufacturer’s recommendations regarding cooling duration to maintain the integrity of your prints. Patience in this step can significantly influence the durability and aesthetic of the final product.

In addition, understanding the cooling process can help tailor your workflow efficiently. By timing different phases of your transfer process, you can optimize productivity without sacrificing quality. For those engaged in high-volume production, adjusting the workflow to accommodate adequate cooling can save time in the long run by preventing repeat failures due to neglecting this critical step.

Maintaining Your DTF Equipment for Optimal Results

Regular maintenance of equipment is paramount for achieving optimal DFT transfer results. Your heat press, a central component of the DTF process, should be routinely cleaned and checked for optimal performance. Residue or dirt can interfere with the transfer quality, leading to inconsistent results. Employing a regular cleaning schedule not only prolongs the lifespan of your heat press but also ensures that each transfer operates at top efficiency, enhancing your overall print quality.

In addition to cleaning, calibrating your heat press regularly is vital. Consistency in temperature and pressure allows for reliable results across multiple batches. Neglecting to maintain these settings may result in variations in print quality, compromising your designs. Therefore, investing time and effort into equipment maintenance is essential for any serious DTF printer aiming for professional and high-quality results.

Frequently Asked Questions

What are common mistakes to avoid in DTF transfers?

When working with DTF transfers, common mistakes include choosing the wrong type of fabric, incorrect temperature and pressure settings, improper fabric preparation, using low-quality images, neglecting cooling time, failing to maintain your heat press, and not conducting test runs before production. Each of these can significantly impact the quality and success of your DTF transfers.

What are some DTF transfer tips for beginners?

For beginners in DTF transfers, essential tips include selecting the right fabric—ideally cotton or its blends—ensuring high-resolution images (at least 300 DPI), properly preparing your fabric by keeping it clean and dry, and adhering to manufacturer guidelines for temperature and pressure settings. Conducting tests before mass production is crucial to guarantee quality.

What are recommended DTF printing techniques for successful transfers?

Successful DTF printing techniques involve using high-quality, specifically designed transfer paper, accurately aligning your designs with registration marks, and maintaining your heat press. Additionally, allowing appropriate cooling time after pressing is critical to prevent lifting or cracking of your DTF transfers.

How can I improve the quality of my DTF transfers?

To improve DTF transfer quality, start with high-quality images, maintain clean and properly prepared fabrics, and use suitable temperature and pressure settings. Regular maintenance of your heat press also ensures consistent performance, while proper alignment of designs helps achieve professional-looking prints.

What should I know about heat press maintenance for DTF transfers?

Maintaining your heat press is vital for achieving high-quality DTF transfers. Regularly clean the heat press to remove any residue or dirt, check all settings for optimal performance, and ensure even pressure distribution. A well-maintained heat press enhances the success rate and quality of your DTF printing projects.

Why is testing important before full production of DTF transfers?

Testing before full production of DTF transfers is crucial to identify and troubleshoot potential issues related to temperature, pressure, and design alignment. Running trial prints helps ensure that your settings are correct and that the transfers will adhere properly, ultimately saving time, resources, and costs associated with errors in larger batches.

| Key Point | Explanation |

|---|---|

| Choosing the Wrong Type of Fabric | Select fabrics like cotton or cotton-blends that bond well with DTF transfers, avoiding high polyester materials which can cause issues. |

| Incorrect Temperature and Pressure Settings | Consult manufacturer settings and perform tests to ensure the correct application of temperature and pressure for optimal results. |

| Improper Fabric Preparation | Ensure fabrics are clean, dry and free from debris before applying transfers to achieve high-quality prints. |

| Using Low-Quality Images | Utilize high-resolution images (at least 300 DPI) to maintain crispness and professionalism in prints. |

| Inattention to Cooling Time | Allow transfers to cool completely before removing the film to prevent lifting or cracking of the print. |

| Neglecting Heat Press Maintenance | Regularly clean and maintain heat press equipment to ensure consistent results in transfer quality. |

| Failing to Test Before Production | Conduct test runs before mass production to troubleshoot settings and ensure success. |

| Improper Design Alignment | Ensure designs are properly aligned with fabric using registration marks for an accurate application. |

| Using Inappropriate Transfer Paper | Select transfer paper specifically designed for DTF applications to avoid adhesion problems and ensure print quality. |

Summary

DTF transfers are an innovative solution for vibrant and intricate textile printing, but avoiding common mistakes is critical for success. From choosing the right fabric to ensuring accurate temperature settings and maintaining equipment, each step plays a pivotal role in achieving exceptional results. By investing time in careful planning and adopting best practices, you can leverage DTF transfers to create stunning and high-quality designs that resonate with your audience.