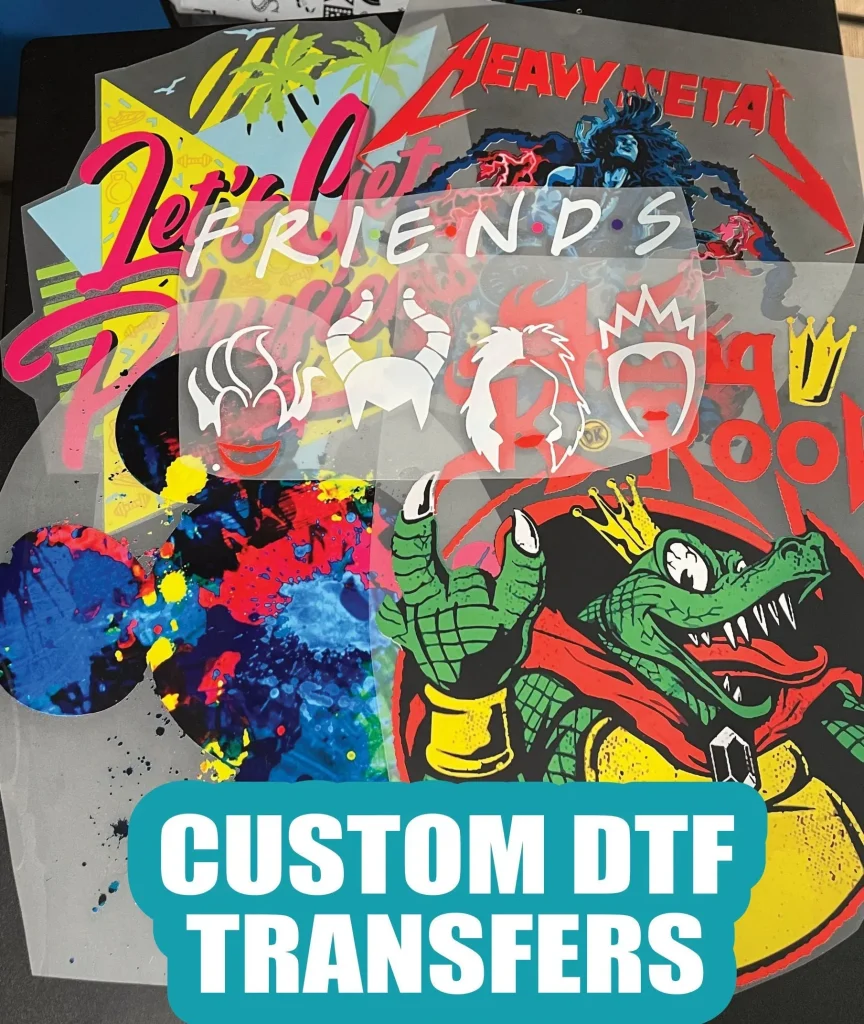

DTF transfers, or Direct-to-Film transfers, have emerged as a groundbreaking method in the printing industry, transforming how designs are transferred onto various fabrics. This innovative technique allows for vibrant, high-quality prints, making it a favorite among both DIY enthusiasts and professional artisans. By utilizing DTF printing techniques, creators can achieve detailed imagery with remarkable precision while enjoying the flexibility to work with a wide range of materials. Essential to successful DTF transfers are the right DTF transfer materials, which encompass specialized films and inks designed to yield optimal results. In this guide, we will explore how to use DTF transfers effectively, ensuring you have everything you need to perfect your craft and satisfy your customers.

Known as Direct-to-Film printing, the method of transferring designs to fabric through advanced technology has gained significant traction in recent years. This approach leverages direct printing onto a film that is subsequently applied to textiles, offering an efficient means to produce stunning visuals. With its capacity to deliver bright colors and intricate details, this fabrication technique is becoming a go-to for crafters and small businesses alike. The versatility of this method allows for printing on a variety of surfaces, making it an appealing option in the competitive market of fabric printing. In this article, we will delve into the step-by-step process, required materials, and valuable tips for maximizing the benefits of this innovative transfer method.

Understanding DTF Printing Techniques

DTF printing techniques represent a significant advancement in the realm of textile printing. This method typically involves innovative software and high-precision printers designed specifically for producing high-quality DTF transfers. The process consists of printing your design onto a specially coated film, which can accommodate a diverse array of prints—from intricate patterns to vivid graphics. Both hobbyists and professional printers are increasingly adopting this technology due to its efficiency and versatility when it comes to fabric types, which range from cotton to synthetic materials.

The appeal of DTF printing lies not just in its practicality but also in the stunning results it yields. Unlike other methods, such as screen printing or direct-to-garment (DTG), DTF allows for the vibrant display of colors and detailed designs, ensuring that every element of the image is captured flawlessly. Moreover, the ability to layer colors and achieve gradients can add a unique flair to any project, making DTF printing techniques a preferred choice among creative minds.

Selecting High-Quality DTF Transfer Materials

Choosing the right materials is crucial to the success of your DTF printing endeavors. High-quality DTF transfer film is a fundamental component, as it facilitates adequate ink adhesion and results in a vibrant final print. Look for films that are specially coated and designed to work with DTF inks, as they ensure the durability of the prints on various fabric surfaces. Additionally, not all films are created equal; investing in reputable brands can save you time, money, and effort in the long run.

Equally important is the selection of DTF inks and adhesive powders. DTF inks should provide bright colors and excellent coverage, which helps in maintaining the integrity of the design post-application. On the other hand, high-quality adhesive powder is crucial for ensuring that prints remain intact during wash cycles. By picking premium materials for your DTF transfers, you not only enhance the aesthetic appeal of your creations but also ensure they withstand the test of time.

Mastering the DTF Design Preparation Process

Preparing your design is a vital step before diving into DTF printing. Utilizing graphic design software, you have the creative freedom to design or modify artwork that will translate beautifully onto fabric. Ensure your design utilizes high-resolution images to maintain quality during the transfer process. High-quality artwork is the foundation of successful DTF transfers and can significantly impact the final look of your product.

After the initial design creation, configuring your printer settings to DTF specifications is equally important. This includes selecting the correct mode for film printing and adjusting the color profiles to produce accurate hues on the transfer film. Performing a test print on regular paper before committing to the transfer film can save you from costly mistakes and help align your expectations with the final output.

Executing the DTF Printing Process

The LSI (Latent Semantic Indexing) terms play a crucial role during the execution of the DTF printing process. The first step is placing the DTF transfer film into the printer, ensuring it is correctly oriented. As the ink prints onto the film, it is essential to allow adequate drying time before moving forward. This attention to detail ensures that you avoid smudges or blurs, which can detract from the overall quality of the final transfer.

Once your print is complete, you will apply a thin, even layer of adhesive powder to the wet ink. This step is critical—using too much or too little adhesive can result in failed transfers. Afterward, curing the print under heat may be necessary according to your film’s instructions, which will secure the bond between the ink and the film for successful transfer to the fabric.

Applying DTF Transfers with Precision

The heat application phase is where all your efforts come together in the DTF transfer process. Setting your heat press to the recommended temperature is crucial—most settings range from 320°F to 350°F (160°C to 180°C). Ensure that you always verify the specific requirements for the film and fabric being used. Proper heat application not only helps in bonding the ink properly but also influences the vibrancy of the colors on the fabric.

During pressing, positioning the DTF transfer accurately is vital to achieve the desired look. A good practice is to align the transfer carefully before applying pressure, ensuring that it does not shift. Typically, you need to press the transfer for approximately 15-20 seconds—optimal timing can depend on the fabric and film you use. After releasing the press, allow the design to cool slightly before peeling away the film, revealing your beautiful new graphic on the fabric.

Eco-Friendly Practices in DTF Transfers

In today’s eco-conscious market, adopting eco-friendly DTF printing practices can significantly enhance your brand’s reputation. Traditional printing methods often generate excess waste and utilize harmful chemicals, but DTF technology tends to be more sustainable. By opting for eco-friendly DTF inks and transfer films, you not only contribute to a healthier environment but also attract customers who care about sustainability.

Moreover, many modern DTF systems are designed to minimize waste during both the printing and transfer process. This reduction in waste proves beneficial for your operational efficiency and resonates with consumers looking to make environmentally sound purchases. By integrating sustainability into your DTF process, you stand to create products that are both appealing and responsibly made.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve printing your design onto a specialized film and then transferring it onto fabric using heat. This technique allows for the use of vibrant colors and detailed designs on various materials, making it increasingly popular for t-shirt printing and other fabric applications.

What materials do I need for effective DTF Printing?

To achieve great results with DTF printing, you will need high-quality DTF transfer film, DTF inks, adhesive powder, and a reliable heat press. These materials ensure your designs are vibrant, durable, and adhere correctly to the fabric.

How do I prepare my design for DTF transfers?

Preparing your design for DTF transfers requires using graphic design software to create or modify your artwork in high resolution. Ensure your printer is set to the correct settings for DTF printing on film, and perform a test print on regular paper before printing on the transfer film.

What heat settings should I use for DTF transfer application?

For applying DTF transfers, set your heat press to between 320°F to 350°F (160°C to 180°C). The specific temperature may vary depending on the type of DTF transfer film and fabric being used, so always check the manufacturer’s recommendations.

How can I ensure my DTF Transfers are long-lasting?

To ensure the longevity of your DTF transfers, allow adequate curing time after application and provide proper washing instructions for the end users, such as washing inside out in cold water and avoiding bleach. Testing the durability with wear and wash cycles before selling is also advisable.

Are there eco-friendly options for DTF printing?

Yes, there are eco-friendly DTF printing technologies that help minimize waste and align with sustainable practices. By choosing eco-friendly DTF transfer materials and inks, you can enhance your brand’s appeal to environmentally conscious consumers while maintaining high-quality print results.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A method of printing designs onto special film that is then transferred onto fabric using heat. |

| Materials Needed | DTF transfer film, DTF inks, adhesive powder, heat press. |

| Preparing Your Design | Use graphic design software, adjust printer settings, and perform a test print. |

| The Printing Process | Print the design on DTF film, apply adhesive powder, and cure if needed. |

| Heat Application | Set the heat press to recommended temperature, align transfer, apply pressure and peel once cooled. |

| Post-Application Care | Allow curing time, educate on washing instructions, and test durability before sales. |

| Eco-Friendly Considerations | Opt for sustainable DTF technologies to reduce waste and align with eco-conscious values. |

Summary

DTF transfers, or Direct-to-Film transfers, offer a game-changing approach to fabric printing, making them indispensable for both professionals and enthusiasts. In this guide, we explored the essential aspects of DTF transfers, ranging from material selection to the intricacies of the printing process. By utilizing high-quality materials and following precise techniques, you can achieve stunning, durable designs that stand out. Additionally, embracing eco-friendly practices can enhance your brand’s appeal, aligning with the growing demand for sustainability. Mastering DTF transfers not only elevates your projects but also positions you ahead in the competitive world of fabric printing.