The DTF Gangsheet Builder has emerged as a revolutionary tool in the realm of Direct-to-Film (DTF) printing, transforming the approach to garment decoration. This innovative builder enables users to create gang sheets with multiple designs efficiently, maximizing the use of DTF transfer film while minimizing material waste. With its ease of use, it caters to both seasoned printers and newcomers in the print-on-demand industry. By utilizing this powerful software, users can capitalize on the cost-effectiveness and efficiency associated with gang sheets, ensuring that every print run is optimized. As the garment printing industry embraces new technologies, mastering the DTF Gangsheet Builder is essential for those looking to stay ahead of the competition.

In today’s dynamic printing landscape, the creation of high-quality transfer sheets through the DTF Gangsheet Builder is a key strategy for businesses involved in garment decoration. Known for its ability to allow several designs on a single film sheet, the gang sheet technique has become indispensable in the print-on-demand sector. By consolidating designs, users can optimize resources, ensuring a more efficient printing process. Furthermore, the versatility of DTF printing appeals to a wide range of applications, making it suitable for diverse client needs. Whether referred to as transfer sheets or gang prints, leveraging these tools is crucial for any printer aiming to enhance productivity and reduce costs.

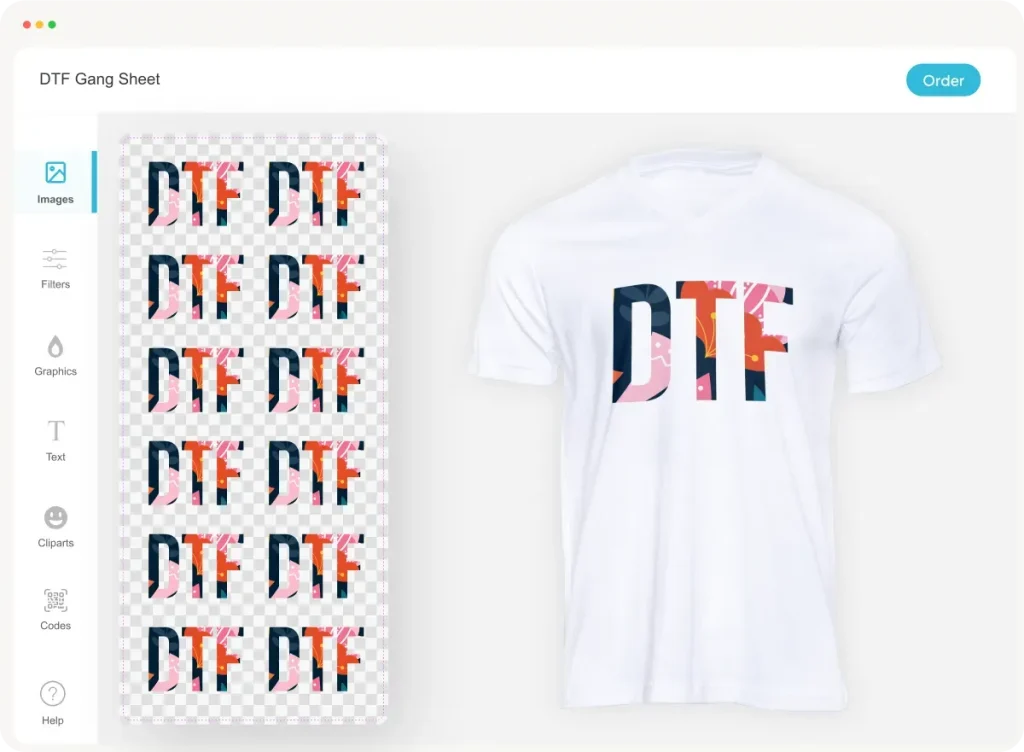

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is a powerful tool that revolutionizes the way printers create designs for garment decoration. By allowing multiple designs to be arranged on a single sheet, it not only enhances productivity but also minimizes material waste. This is particularly beneficial in the print-on-demand industry, where efficiency is essential for meeting tight deadlines and customer demands. With the Gangsheet Builder, users can seamlessly optimize their designs, ensuring that every inch of DTF transfer film is utilized effectively.

Moreover, the efficiencies gained through the DTF Gangsheet Builder translate directly into cost savings. As businesses are able to produce more designs in one go, they significantly reduce expenses related to printing films and inks. This method also cuts down the setup time between print jobs, allowing for a quicker turnaround on orders. For businesses striving for profitability, implementing the DTF Gangsheet Builder can be a game-changer in how they operate and deliver products.

Understanding DTF Printing Fundamentals

DTF printing, or Direct-to-Film printing, is a modern method used in the garment industry for transferring designs onto fabrics. The process involves printing designs onto transfer film that is later heat-pressed onto the clothing. This technique has changed the landscape of garment printing by enabling vibrant colors and intricate designs to be transferred quickly and efficiently. Furthermore, DTF printing allows for a diverse range of fabrics to be printed on, catering to the varying needs of the market.

One of the key components of successful DTF printing is mastering the use of gang sheets. Gang sheets allow for multiple designs to be printed simultaneously, optimizing the use of transfer film and inks. By utilizing this technique, printers can minimize waste, resulting in a more sustainable operation. The flexibility of gang sheets enables businesses to offer a wider variety of designs without the need for extensive setup, making it an essential part of the DTF printing process.

Benefits of Utilizing Gang Sheets in DTF Printing

Adopting gang sheets within the DTF printing process yields a multitude of benefits. First and foremost, it provides substantial cost savings by maximizing the efficient use of transfer film. Instead of printing one design per sheet, printers can optimize layouts to produce several designs, reducing material costs per unit. This economical approach is especially critical for startups and small businesses that need to keep costs low while still providing high-quality prints.

In addition to cost-effectiveness, gang sheets enhance operational efficiency. The setup time is significantly reduced, allowing businesses to fulfill orders more quickly. By arranging designs on a single sheet, printers can streamline their workflow, which is crucial in today’s fast-paced market. This level of efficiency empowers printers to take on larger volumes and meet the rising demand for diverse designs, ultimately driving growth for print-on-demand services.

Step-by-Step Guide to Setting Up Your Designs

When it comes to implementing DTF printing, the initial setup plays a crucial role in the quality of the final product. Users must first open their design software and create a new canvas based on the size specifications of the DTF transfer film. The precise scaling of imported designs is critical to ensure they do not overlap when arranged on the canvas. This meticulous approach not only aids in visualizing the end product but also minimizes adjustments needed post-printing.

Once the designs are imported, arranging them in an optimal way on the canvas is essential. Using either grid or freeform layouts can help maximize the space on the gang sheet, resulting in less wasted film. Careful planning at this stage translates into a smoother printing process and better overall results, allowing for effective use of both the transfer film and resources. This step also establishes the groundwork for the print job’s success.

Expert Tips for Utilizing the DTF Gangsheet Builder

When using the DTF Gangsheet Builder, it’s critical to understand the settings available for optimal results. Fine-tuning aspects such as ink density and color profiles to match those of your printer can significantly impact the vibrancy and accuracy of the colors in the final prints. Each DTF printer may have its specific requirements, making it essential for users to familiarize themselves with these before proceeding. Such attention to detail ensures that the prints will not only look great but also stand the test of wear and washing.

Additionally, a final preview before exporting your gang sheet is a best practice that shouldn’t be overlooked. This step allows printers to catch any potential issues—like alignment problems or color mismatches—that could detract from the overall quality of the prints. Taking time to verify these elements before sending the print job can save hours of reprinting and corrections later. By mastering these tips, users can truly harness the full potential of the DTF Gangsheet Builder.

Achieving Quality Prints with DTF Transfer Film

The choice of DTF transfer film is integral to achieving high-quality results in garment printing. Various types of films have different properties, affecting everything from how well the print adheres to fabric to the vibrancy of colors. Selecting the right film for your printer and the specific materials you are printing on is paramount for achieving the best results. By investing in quality DTF transfer films that are compatible with your designs, you can enhance the durability and aesthetic appeal of your prints.

Moreover, understanding the curing process post-printing is critical. Designs printed on the transfer film require adequate drying or curing to ensure that the ink bonds properly with the film. Following the manufacturer’s instructions closely regarding heat and time will lead to better longevity and resistance to washing. This aspect of DTF printing ensures that the end products maintain their quality over time, which is vital for customer satisfaction in the competitive world of garment printing.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for users in the Direct-to-Film (DTF) printing industry. It allows printers to create gang sheets by arranging multiple designs on a single DTF transfer film. This process optimizes film usage, reduces material waste, and enhances printing efficiency, making it an essential tool for businesses and hobbyists in garment printing.

What are the primary benefits of using gang sheets in DTF printing?

Using gang sheets in DTF printing provides several benefits including cost-effectiveness by reducing film and ink usage, increased efficiency by allowing multiple designs to be printed simultaneously, and versatility as it accommodates a wide range of design options. This not only saves time but also maximizes the productivity of your print-on-demand operations.

How do I set up my designs for the DTF Gangsheet Builder?

To set up your designs for the DTF Gangsheet Builder, first, use design software like Adobe Illustrator or CorelDRAW to create a new canvas that matches the size of your DTF transfer film. Import and scale your designs to fit, then arrange them efficiently on the canvas to minimize empty space, ensuring they’re ready for uploading to the Gangsheet Builder tool.

What materials do I need to use the DTF Gangsheet Builder successfully?

To use the DTF Gangsheet Builder effectively, you will need a computer with design software, high-quality images or vector files for your designs, access to DTF transfer film, and ink for your DTF printer. These materials are essential for creating and printing your gang sheets successfully.

What steps are involved in printing a gang sheet with a DTF printer?

Printing a gang sheet with a DTF printer involves several key steps: 1) Set up your printer and load it with DTF transfer film; 2) Send the gang sheet design from your software to the printer; 3) Monitor the print quality during the process; and 4) Cure the print as per the DTF film manufacturer’s instructions to ensure quality before transferring to garments.

How does the DTF transfer process work after using the DTF Gangsheet Builder?

After using the DTF Gangsheet Builder and printing your designs, the transfer process involves preheating your heat press, preparing the garments, and positioning the gang sheet on the fabric. Apply pressure and heat for the specified time, then allow it to cool before carefully peeling off the backing to reveal the high-quality prints on the garment.

| Step | Description |

|---|---|

| Step 1: Gather Your Materials | Collect your design software, images, DTF transfer film, and ink. |

| Step 2: Setting Up Your Designs | Open your design software and arrange your designs effectively on a new canvas. |

| Step 3: Using the DTF Gangsheet Builder | Upload your design canvas, configure printer settings, and preview the gang sheet. |

| Step 4: Preparing for Printing | Prepare your printer and load the DTF transfer film correctly. |

| Step 5: Printing Your Gang Sheet | Start the print job and monitor quality, then cure the prints as required. |

| Step 6: Transfer Process | Preheat heat press, position your gang sheet on the garment, and press for the recommended time. |

Summary

DTF Gangsheet Builder is an essential tool for anyone looking to enhance their printing efficiency and creativity. This comprehensive tutorial provides detailed steps to successfully create and use gang sheets, allowing for more effective use of materials while reducing overall costs. By mastering each stage, from gathering materials to the final transfer process, users can significantly improve their garment printing capabilities. As the demand for quality printed textiles continues to grow, utilizing the DTF Gangsheet Builder becomes a strategic advantage for both small businesses and seasoned professionals in the printing industry.